Optical adjustment platform for quantum optical test

A technology of optical adjustment and quantum optics, which is applied in the direction of laboratory stools/lab tables, educational appliances, teaching models, etc., can solve the problems of insufficient portability, optical lenses can only be adjusted in one dimension, and the adjustment direction is limited, so as to achieve convenience The effect of folding and carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

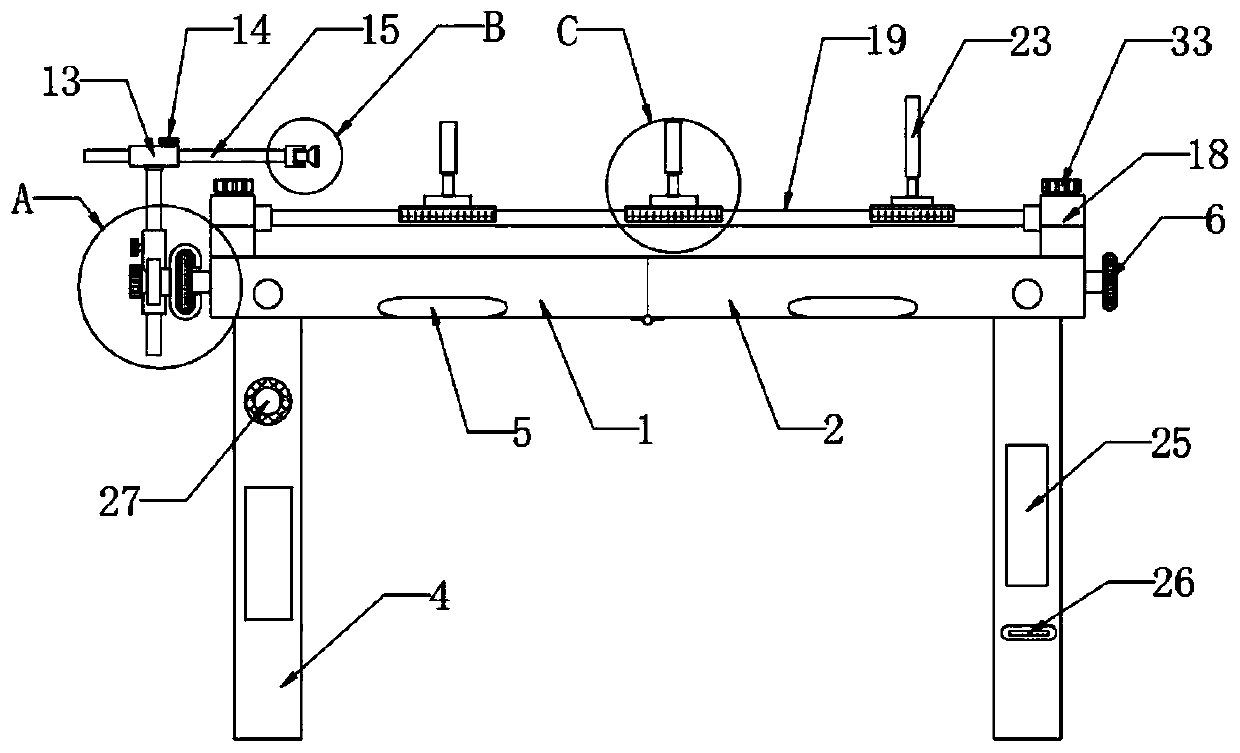

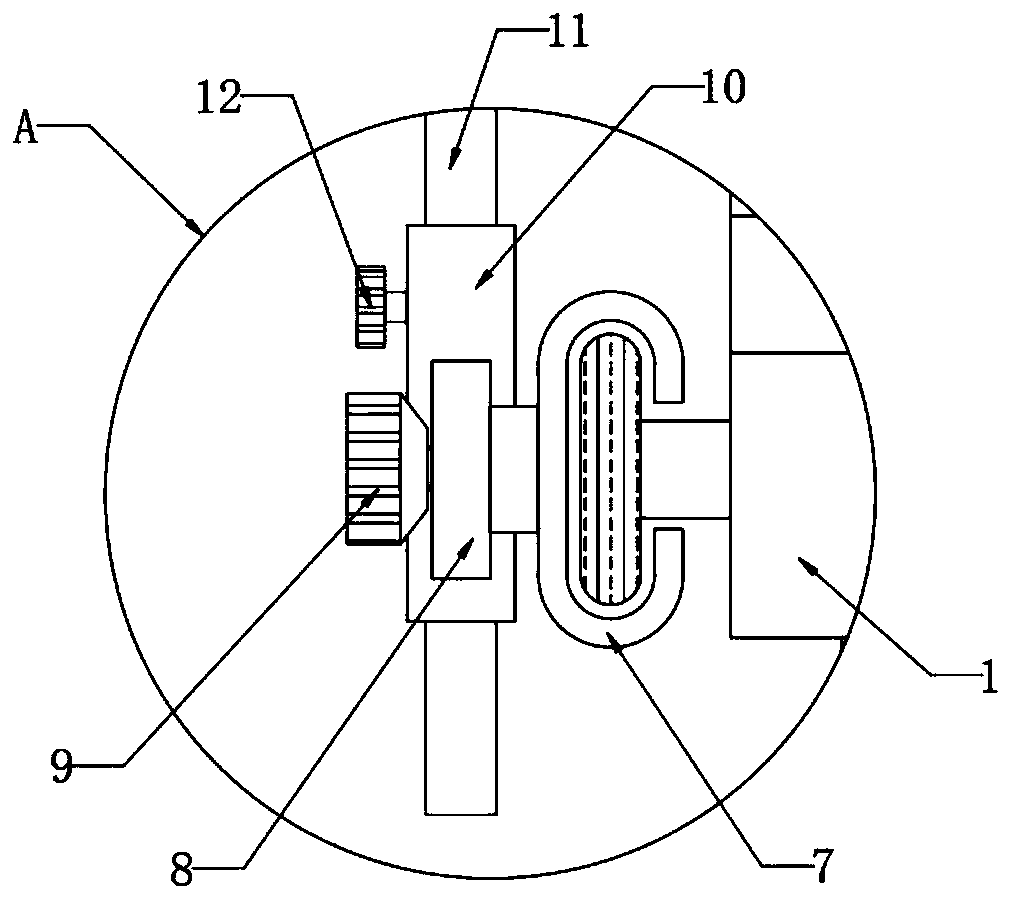

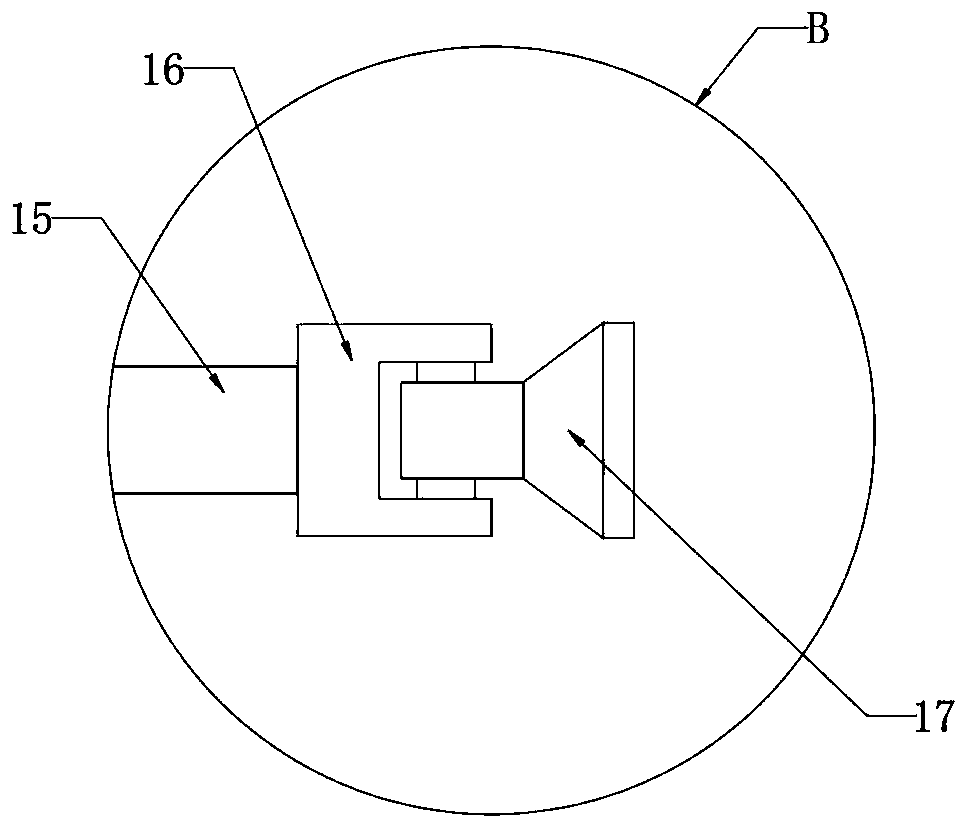

[0030] Embodiment 1: When the device is in use, first slide the adjustment slider 7 along the length direction of the adjustment slide rail 6 to adjust the position of the light source lamp 17 on the side of the test bench, and then slide along the length direction of the lifting sleeve 10 Adjust the lifting rod 11 so that the light source lamp 17 moves up and down with the lifting rod 11, thereby adjusting the height of the light source lamp 17 to a suitable position, and then rotate the first locking bolt 12 so that the lifting rod 11 is opposite to the lifting sleeve 10 Fix, then turn the level adjustment sleeve 13, so that the level adjustment sleeve 13 drives the level adjustment rod 15 to rotate to adjust the horizontal irradiation angle of the light source lamp 17, then slide the level adjustment rod 15 along the length direction of the level adjustment sleeve 13 , and the light source lamp 17 moves along with the horizontal adjustment rod 15, so as to reach the horizont...

Embodiment 2

[0031] Embodiment 2: By extracting the adjusting rod seat 18 from the inside of the mounting hole 24, then removing the adjusting rod 19 from the adjusting rod seat 18, and removing the lens seat 20 from the adjusting rod 19, by pulling the adjusting rod seat 18. Put the adjustment rod 19 and the lens holder 20 into the storage tank 3 to complete the storage of the adjustment rod holder 18, the adjustment rod 19 and the lens holder 20; And the horizontal adjusting rod 15 is taken off from the adjusting slide rail 6, then the first locking bolt 12 and the second locking bolt 14 are rotated, so that the lifting rod 11 and the horizontal adjusting rod 15 are separated from the lifting sleeve 10 and the horizontal adjusting sleeve respectively. The inside of the cylinder 13 is separated, and the fixing plate 8, the lifting sleeve 10, the level adjusting sleeve 13, the lifting rod 11 and the level adjusting rod 15 are all put into the inside of the storage tank 3, and the fixing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com