Mistaken-touch-preventing power strip for industrial production

A technology of preventing accidental contact and plug-in, which is applied in the direction of preventing contact with live contact devices, electrical components, coupling devices, etc., can solve the problems of power failure and shutdown of production lines, and achieve stable power connection process, simple manufacturing, and avoidance of disconnection. effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

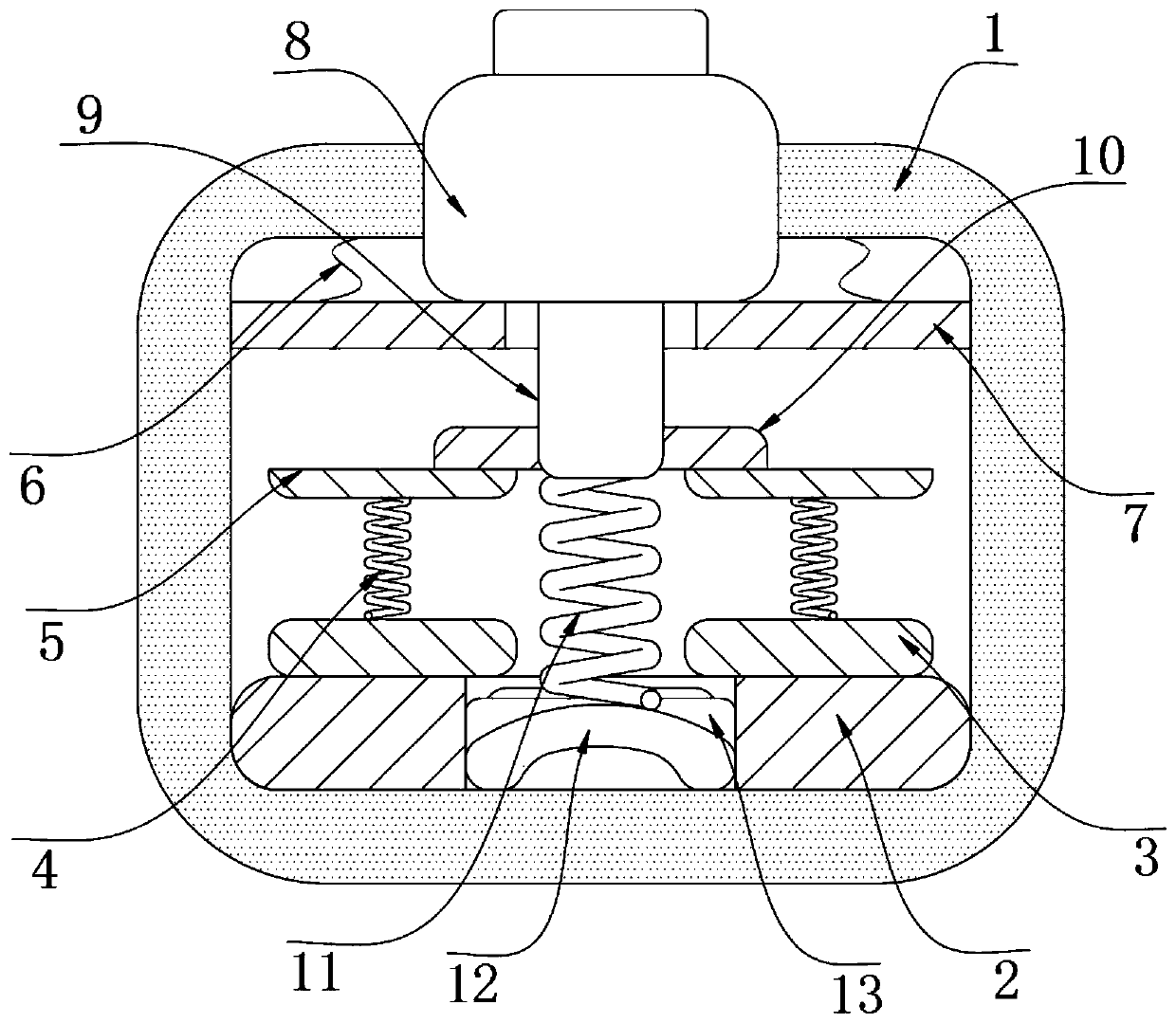

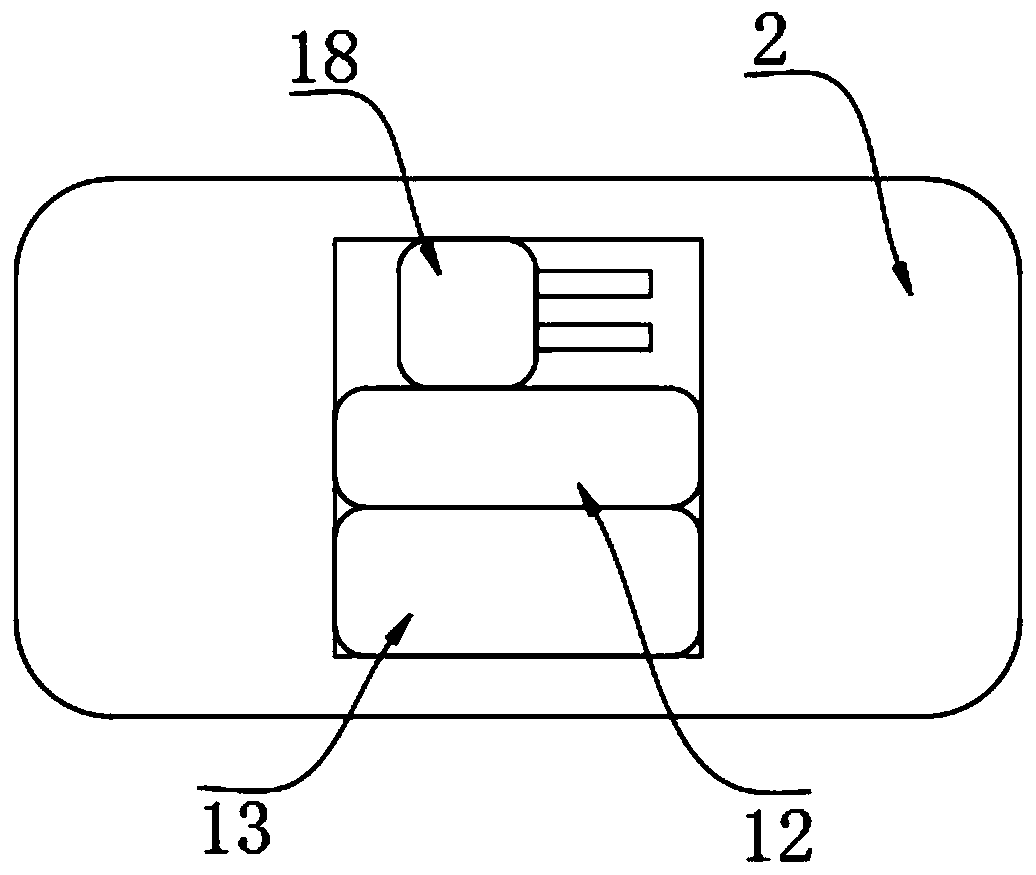

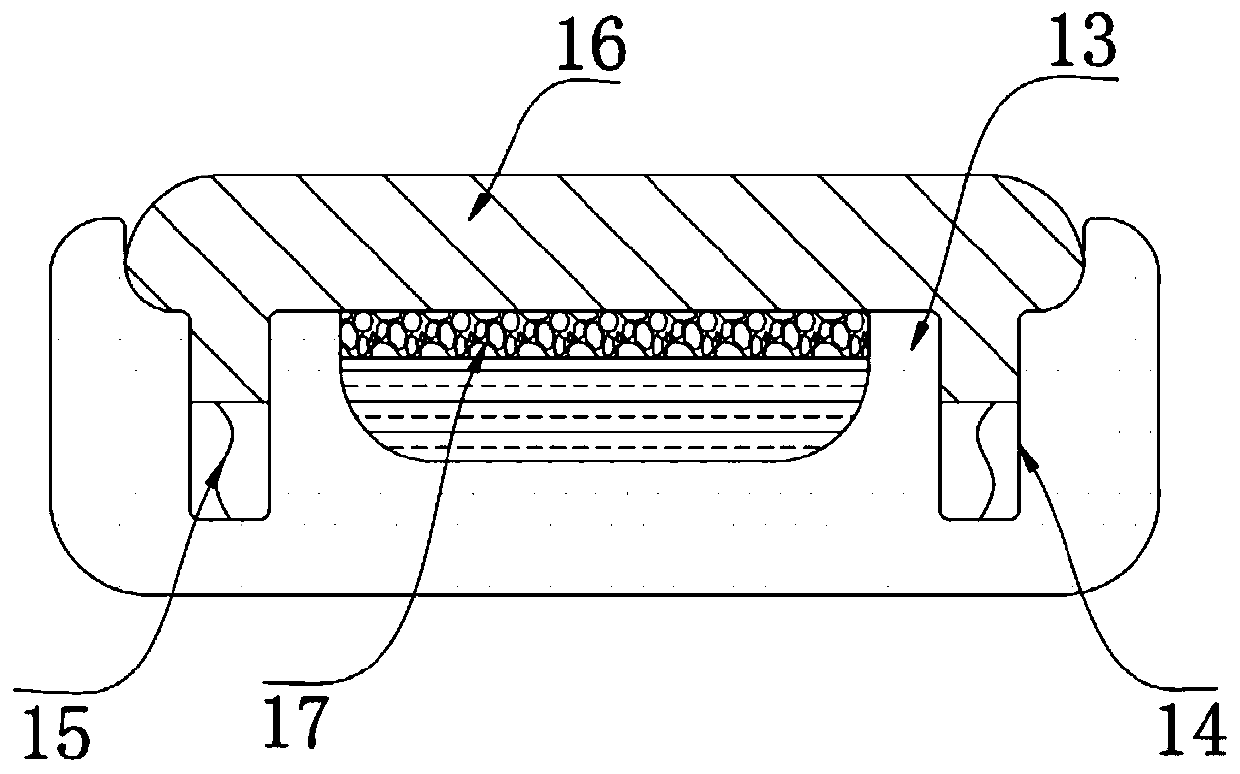

[0018] refer to Figure 1-3 , an anti-mistouch plug-in strip for industrial production, comprising a housing 1, a fixing frame 2 is fixed on the inner bottom of the housing 1, two symmetrically arranged power connecting plates 3 are fixed on the upper end of the fixing frame 2, and the two power connecting plates 3 The upper ends of the upper ends are connected with the connecting piece 5 through the compression spring 4, and the inner top of the shell 1 is fixed with the carrying plate 7 through the carrying spring 6, and the upper end of the carrying plate 7 is fixed with a self-locking button 8 that runs through the top of the shell 1, and the self-locking button 8 is a commonly used button for plugging in and out, which is not repeated here for the mature existing technology. The bottom of the self-locking button 8 is fixed with an insertion rod 9, and the circumferential side wall of the insertion rod 9 is fixed with a connecting ring 10. The bottom of the insertion rod 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com