Controllable fuse, fuse assembly and control method

A fuse and fusing technology, applied in the direction of relays, electrical components, emergency protection devices, etc., can solve the problems of prolonging research and development time, damage to smart devices, inconvenient use, etc., and achieve the effect of precise overcurrent protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

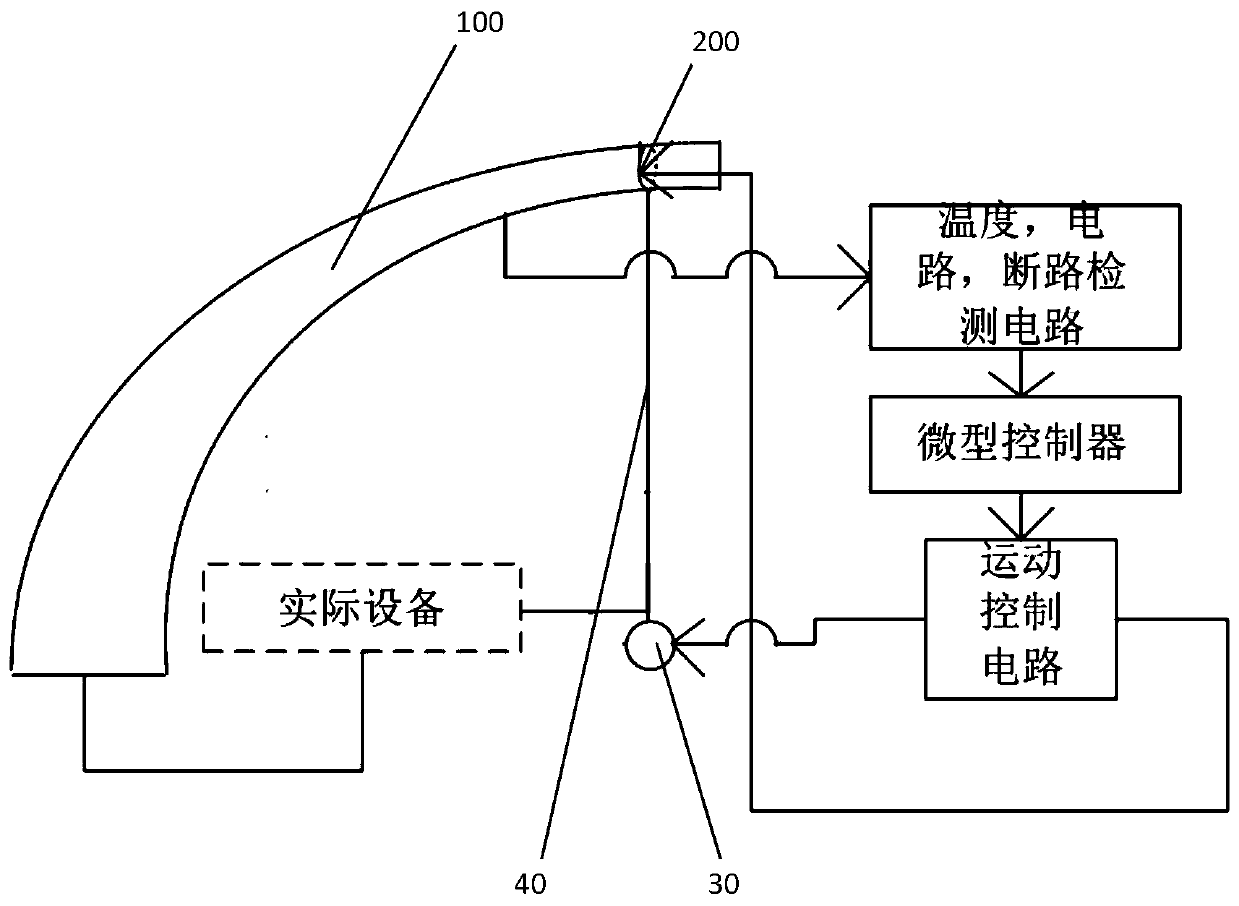

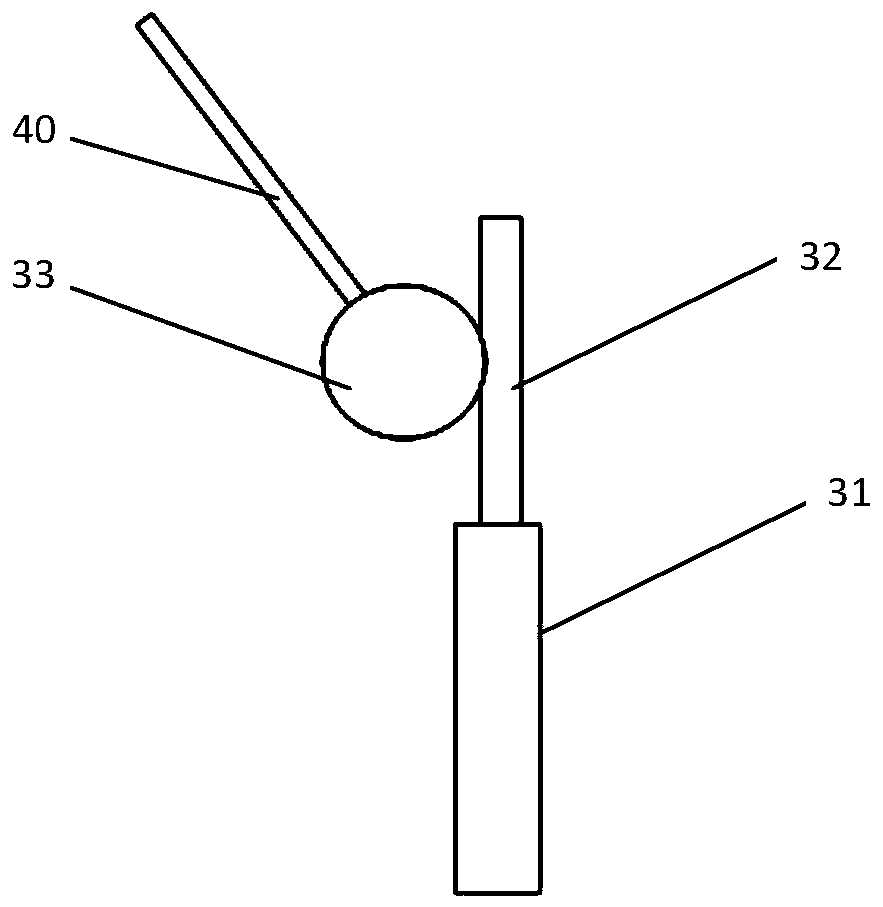

[0021] Please combine figure 1 As shown, this embodiment discloses a fuse assembly, which includes a controllable fuse, a motion controller circuit, a microcontroller circuit and a detection circuit. The controllable fuse includes a fuse metal body 100 , a driving device, and an automatic terminal locking device 200 . The cross-sectional area of the fuse metal body 100 gradually increases from one end of the fuse metal body 100 along the extending direction of the fuse metal body 100; the terminal locking device 200 is conductive, and serves as a terminal and an overcurrent protected device Make an electrical connection. One end of the fuse metal body 100 is used as another terminal to form an electrical connection with the device to be protected from overcurrent. When the fuse assembly is in use, the terminal locking device 200 is in contact with the fuse metal body 100 and moves back and forth along the extending direction of the fuse metal body 100 ; the driving device ...

Embodiment 2

[0029] This embodiment is the control method of the fuse assembly in the first embodiment above. After the controllable fuse is connected to the protected equipment at both ends, the current value signal detected by the detection circuit is transmitted to the control system. The control system controls the end locking device 200 to slide so that the fusing current reaches the set fusing requirement.

[0030] Set the temperature threshold of the fuse metal body. When the detection circuit detects that the current temperature value of the fuse metal body 100 is greater than the temperature threshold and the circuit is not broken, the automatic locking device 200 at the control end performs a loosening action to automatically break the circuit. After a period of time, it automatically locks The device 200 continues to lock the fuse metal body to connect the circuit so that the circuit can work normally. And when the automatic locking device 200 is locked on the same position of the...

Embodiment 3

[0035] Embodiment 3 provides a controllable fuse, which is an independent controllable fuse in Embodiment 1. The independent controllable fuse can be manufactured and used as a single product, including a fuse metal body 100, a drive The device and the terminal automatic locking device 200 realize the selection of different rated fusing currents. Since the controllable fuse in this embodiment is completely the same as the controllable fuse in Embodiment 1, details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com