A photoelectric composite cable

A technology of photoelectric composite cable and optical unit, which is applied in the direction of power cables, insulated cables, power cables including optical transmission components, etc., and can solve the time-consuming and labor-intensive problems of taking out optical units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

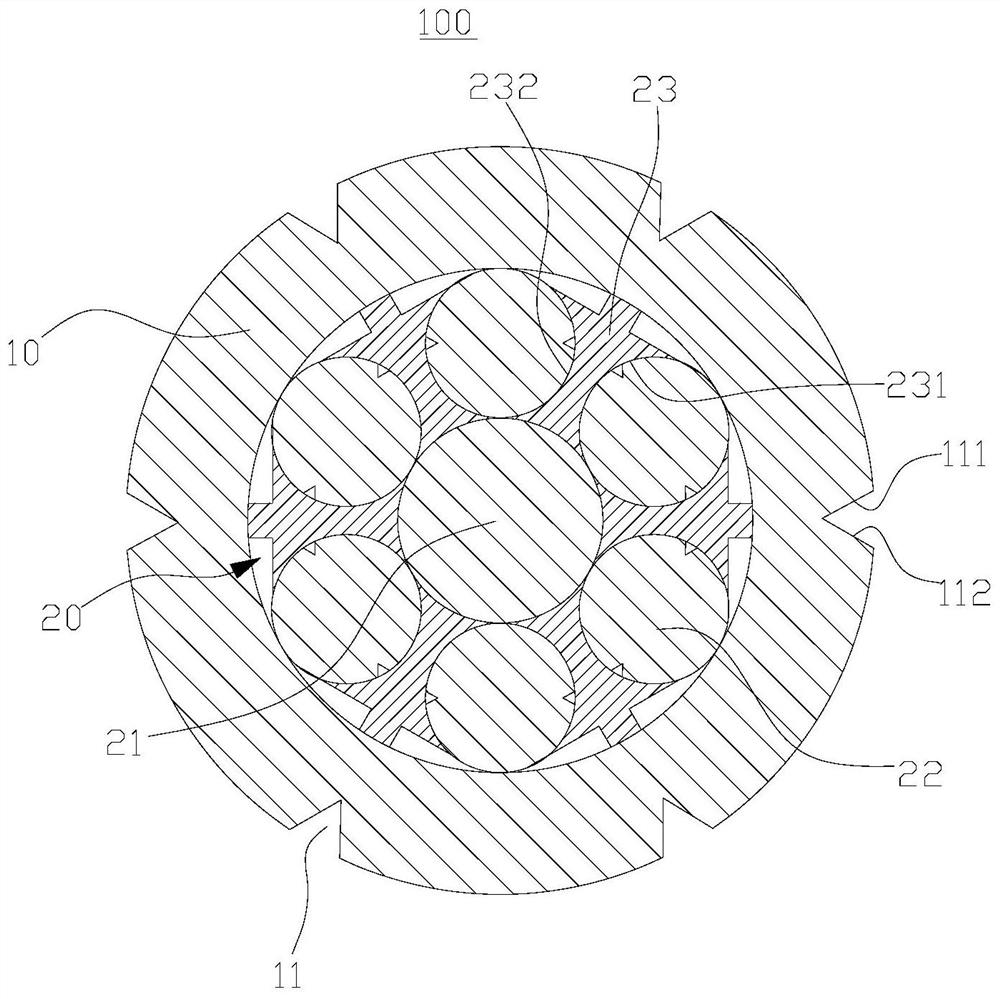

[0047] Such as figure 1 As shown, the embodiment of the present application provides a photoelectric composite cable 100 , including an outer protective layer 10 and a core 20 , and the outer protective layer 10 covers the outer side of the core 20 .

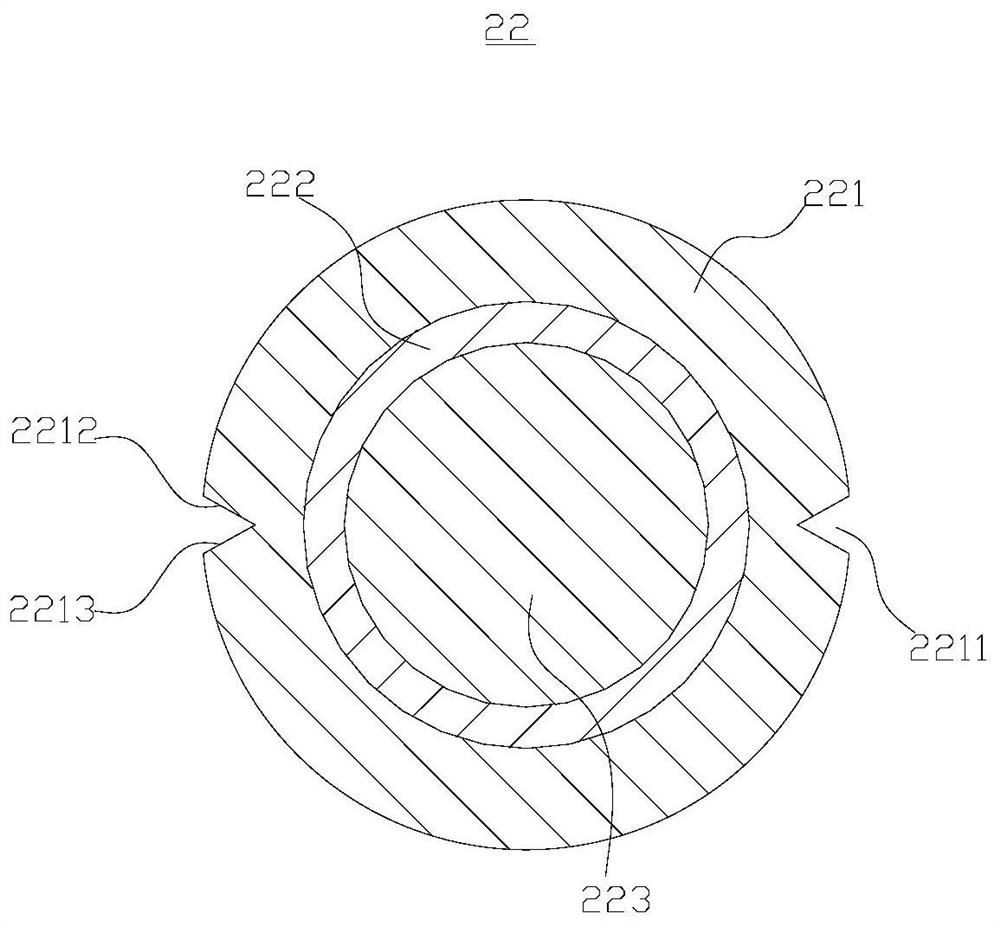

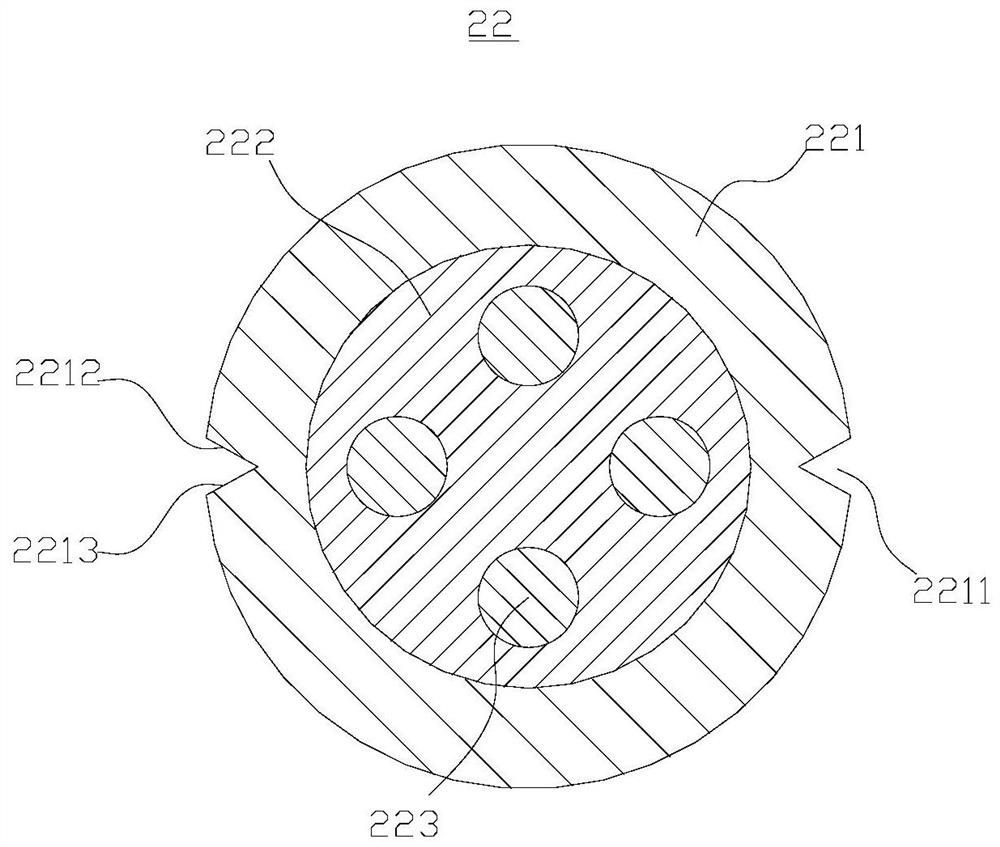

[0048] Wherein, the core body 20 includes an electrical unit 21, a plurality of optical units 22 and a plurality of filling strips 23, and the plurality of optical units 22 are distributed on the outside of the electrical unit 21 at intervals in the circumferential direction. A filling strip 23 is provided in the gap, and a first hand-tear notch 11 is provided on the outer wall of the outer protective layer 10 corresponding to each filling strip 23 .

[0049] In the above structure, a filling bar 23 is provided in every gap between two adjacent light units 22 , and the filling bar 23 can ensure the relative position of the two adjacent light units 22 . Because the position that the first hand tear notch 11 is provided correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com