Multi-sample rapid replacement type scanning probe microscope

A scanning probe, multi-sample technology, applied in the field of scanning probe microscopy, can solve the problems of large thermal fluctuations, bulky, and reduced imaging quality, and achieve improved scanning imaging accuracy, convenient control signals, and consistent thermal fluctuations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

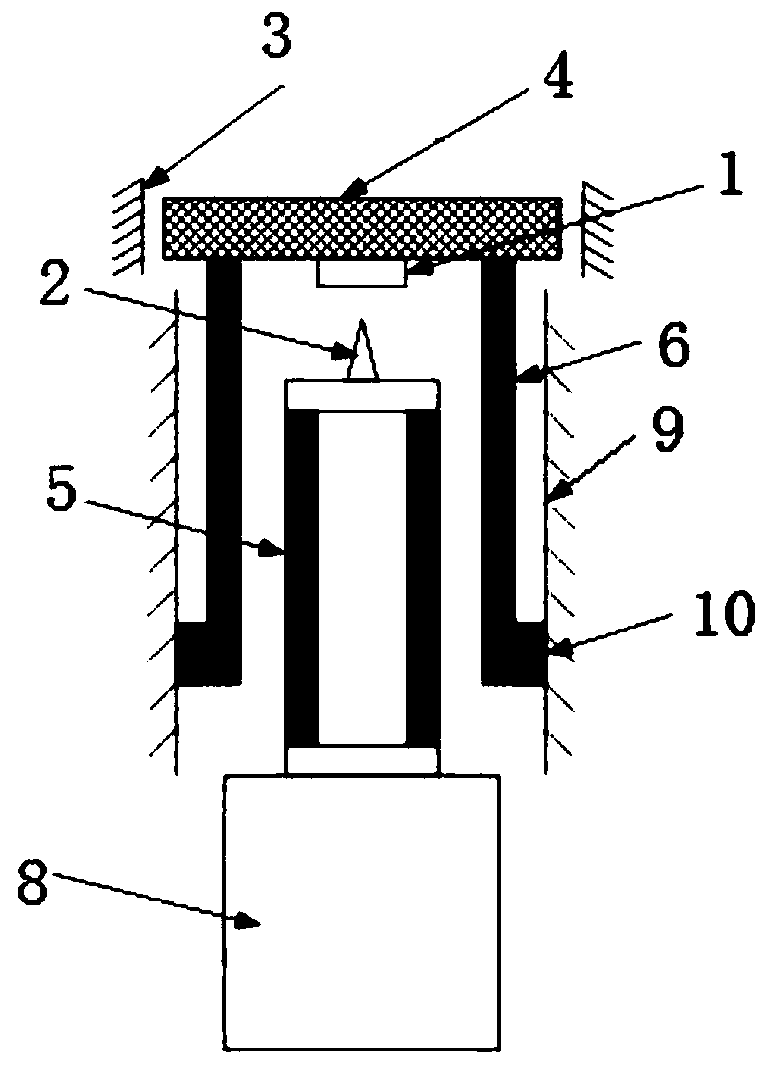

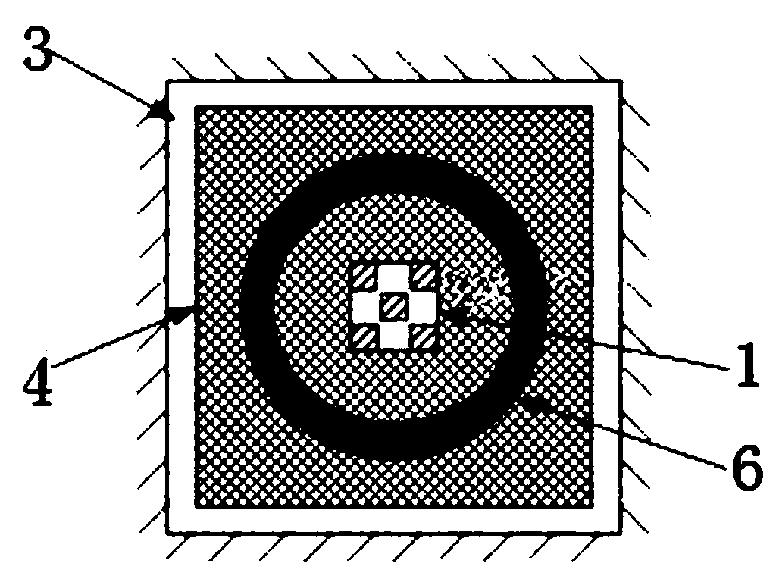

[0033] like Figure 1 to Figure 3 As shown, the braking motor pushes the scanning tube 5 and the probe 2 to approach (or move away from) the sample surface (Z direction), and the scanning tube 5 controls the probe 2 to perform two-dimensional scanning in the XY direction. The piezoelectric tube 6 and the scanning tube 5 belong to a nested relationship, and applying a spike signal to the piezoelectric tube can control the swing of the mass in the XY direction (equivalent to an inertial motor). The sample stage 1 is fixed on the mass block 4, such as figure 2 As shown, in the initial state (that is, when the mass block 4 is in the center of the XY limit device 3 ), the probe 2 is facing the sample at the center, which can be scanned and imaged. After scanning, the probe 2 is controlled to retreat a certain distance, and then the piezoelectric tube 6 is controlled to swing so that the mass block 4 drives the sample to move in the XY direction. This movement does not need to ca...

Embodiment 2

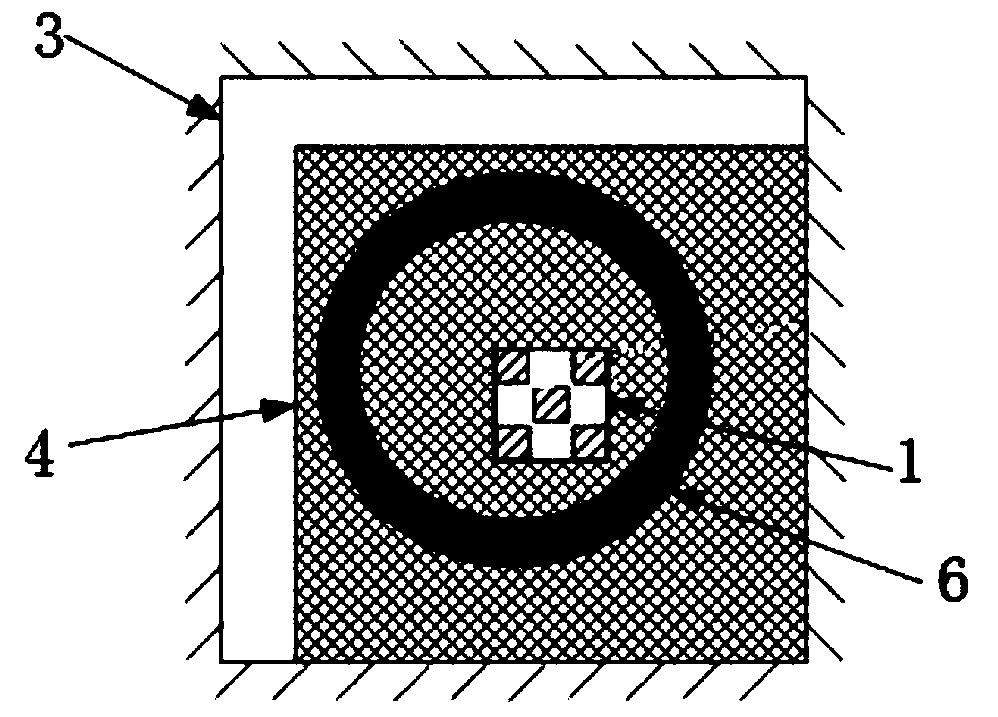

[0035] like Figure 4 As shown, on the basis of Embodiment 1, the positions of the probe 2 and the sample stage 1 are exchanged, the piezoelectric tube 6 drives the mass block 4 to move in the XY position, and the XY limit device 3 can make the probe 2 respectively align Five samples on the quasi-sample stage 1 (mass block 4 is in the center of the limit device in the initial state, and probe 2 is facing the central sample). During scanning, the scanning tube 5 applies a scanning signal to drive the sample to scan, and the probe 2 does not move during the scanning process.

Embodiment 3

[0037] like Figure 5 to Figure 7 As shown, on the basis of the first embodiment, the functions of the scanning tube 5 and the piezoelectric tube 6 are interchanged. The sample stage 1 is fixed on the mass block 4 connected with the piezoelectric tube 6 , and the probe 2 is fixed on the free end of the scanning tube 5 . The piezoelectric tube 6 controls the mass block 4 to perform inertial swinging in the XY direction, and the scanning tube 5 controls the probe 2 to scan, and the scanning of 5 samples can also be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com