A feeding device for cloth inspection machine

A cloth inspection machine and fabric technology, applied in the field of cloth inspection machines, can solve problems such as troublesome operation, waste of time, and increase the work intensity of workers, and achieve the effects of convenient operation, reduced labor intensity, and improved cloth inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

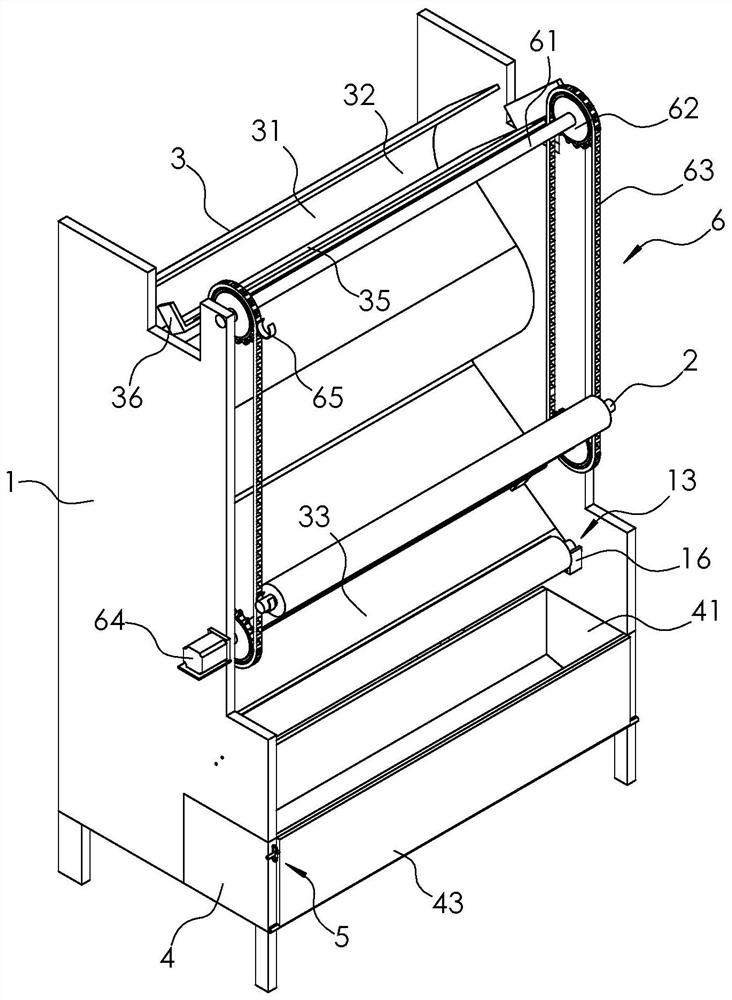

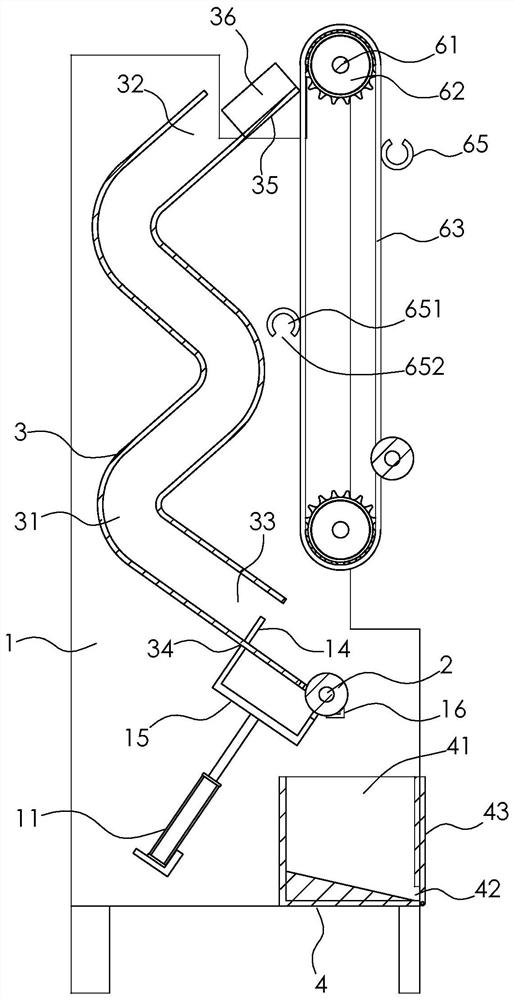

[0037] Such as figure 1 and figure 2 As shown, a feeding device for a cloth inspection machine includes a bracket 1 and a material shaft 2. Cloth is wound on the material shaft 2. Two sets of serpentine plates 3 arranged at intervals are fixed on the bracket 1. The two groups The serpentine plate 3 and the bracket 1 together form a serpentine channel 31 , and the upper and lower sides of the serpentine channel 31 are respectively provided with a material inlet 32 and a material outlet 33 . Multiple sets of material reels 2 can be placed in the serpentine passage 31, realizing the material preparation of the material reels 2.

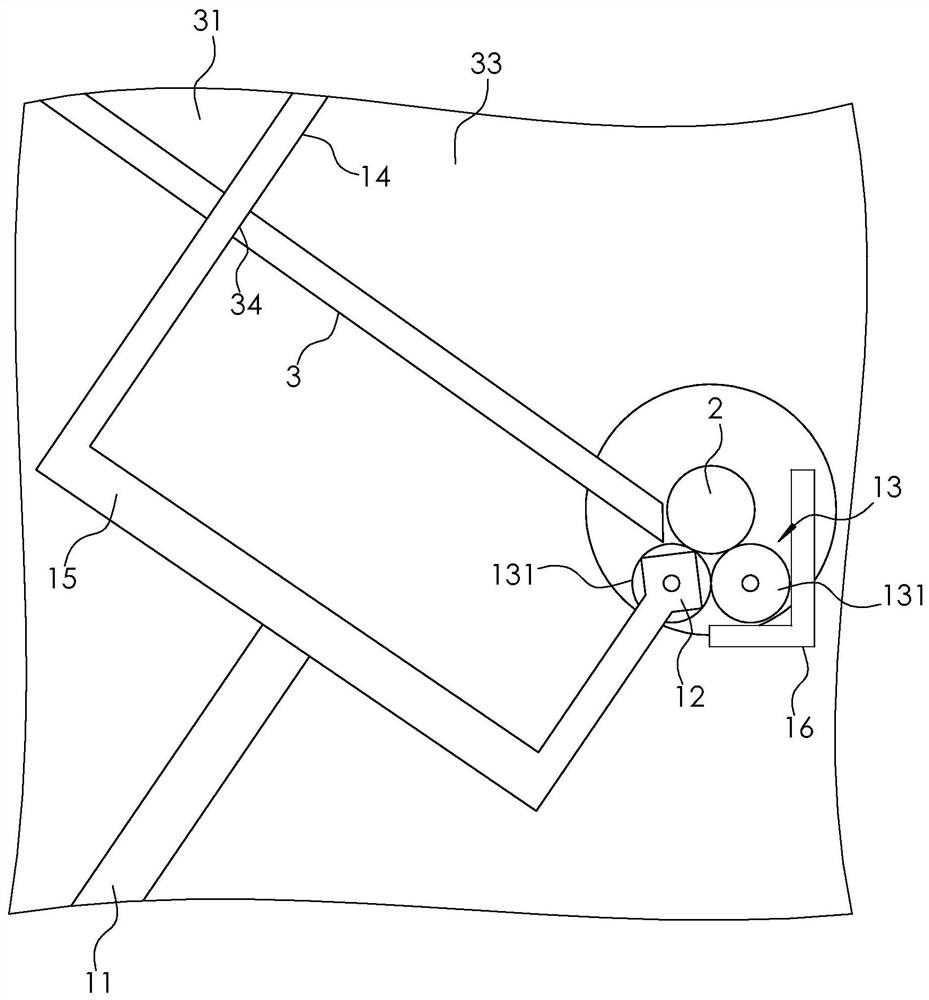

[0038] Such as image 3 and Figure 4 As shown, the bracket 1 is provided with two groups of mounting brackets 12 and two groups of rotating parts 13 located at the outlet 33, each rotating part 13 includes two groups of runners ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com