Hard box screen printing auxiliary packaging equipment

A technology of packaging equipment and silk screen printing device, which is applied in the field of hard box silk screen printing auxiliary packaging equipment, can solve the problems of inconvenient collection and packaging, difficulty in accurate silk screen printing, etc., and achieve the effect of convenient collection and packaging, accurate silk screen collection and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

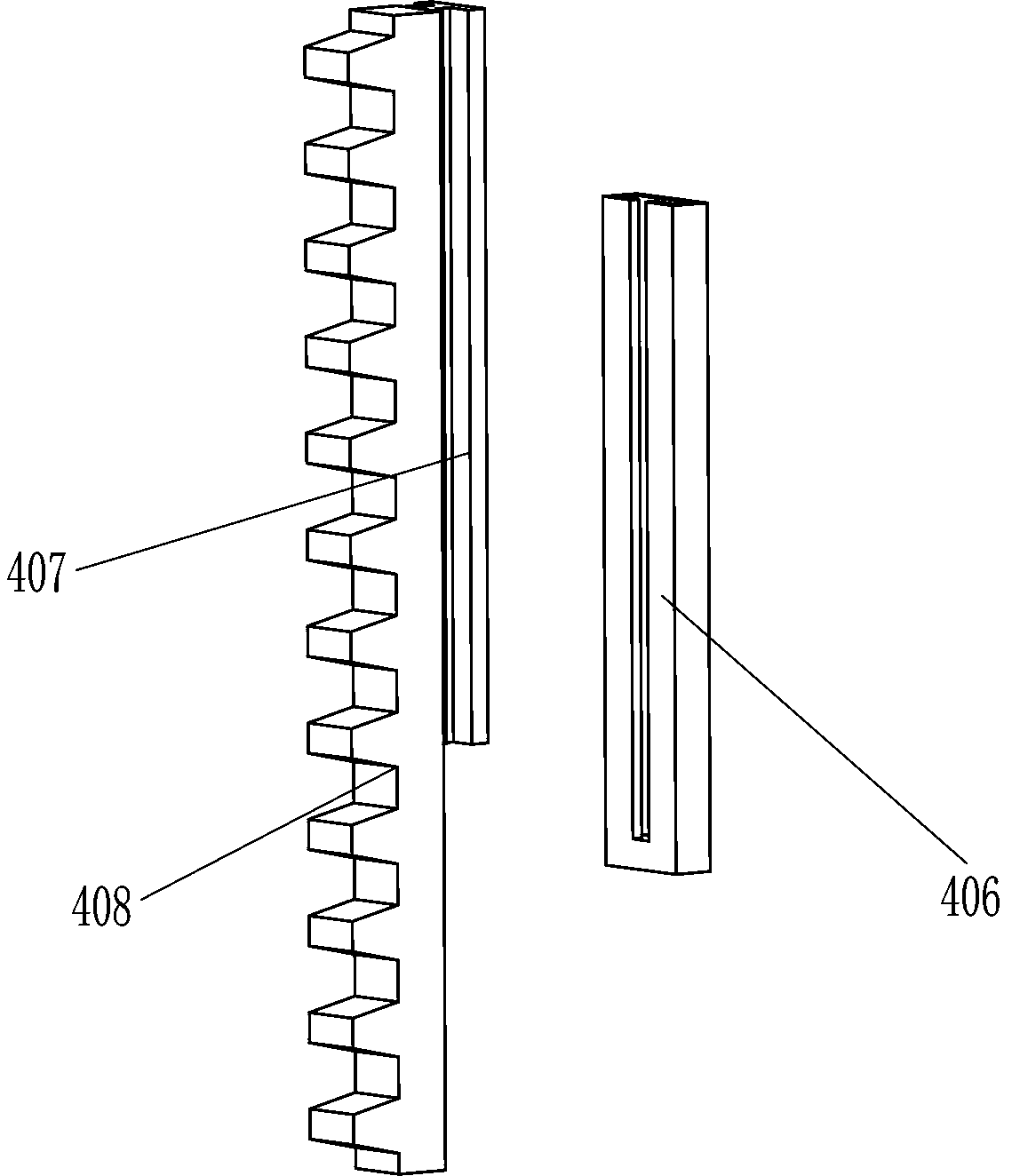

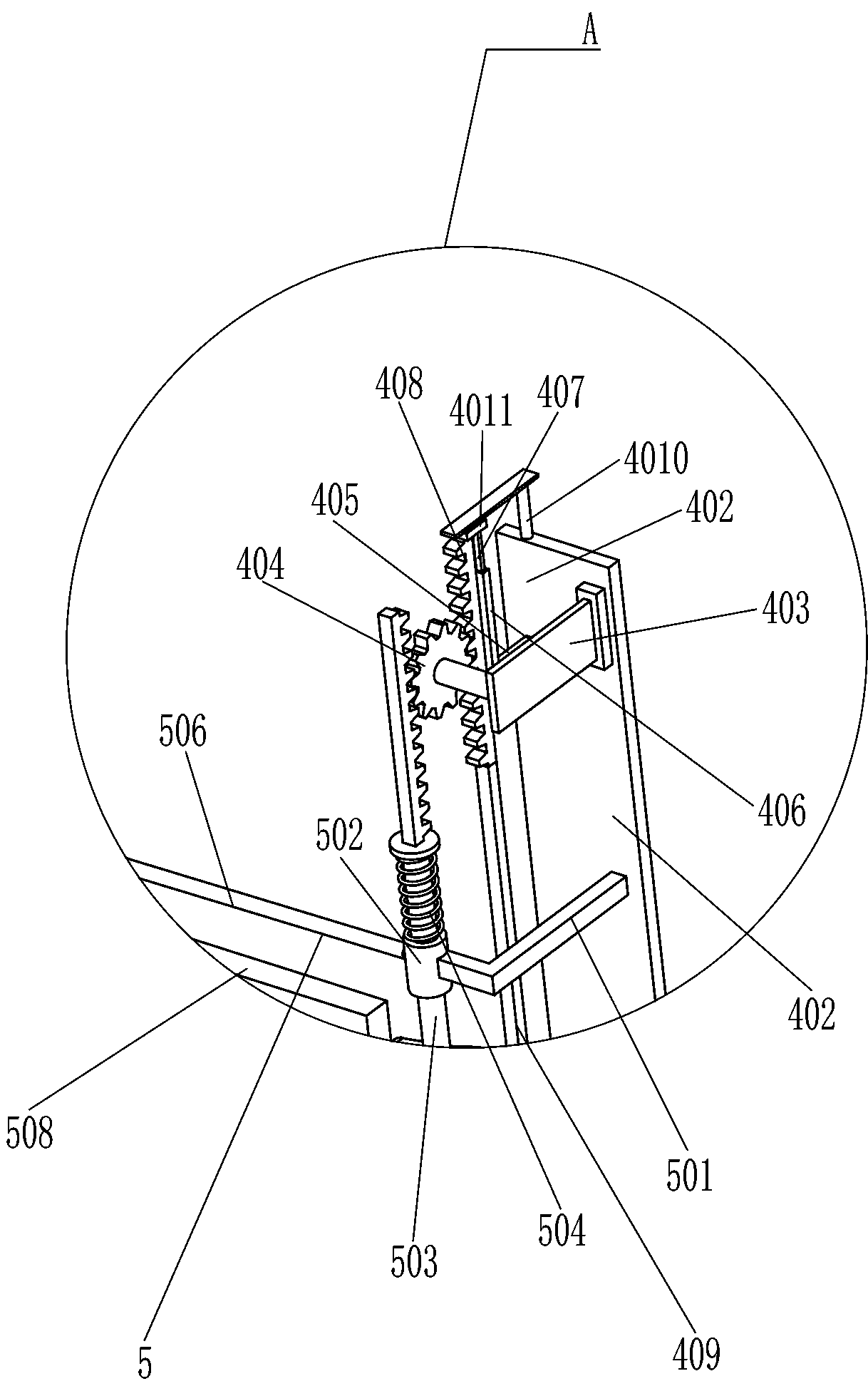

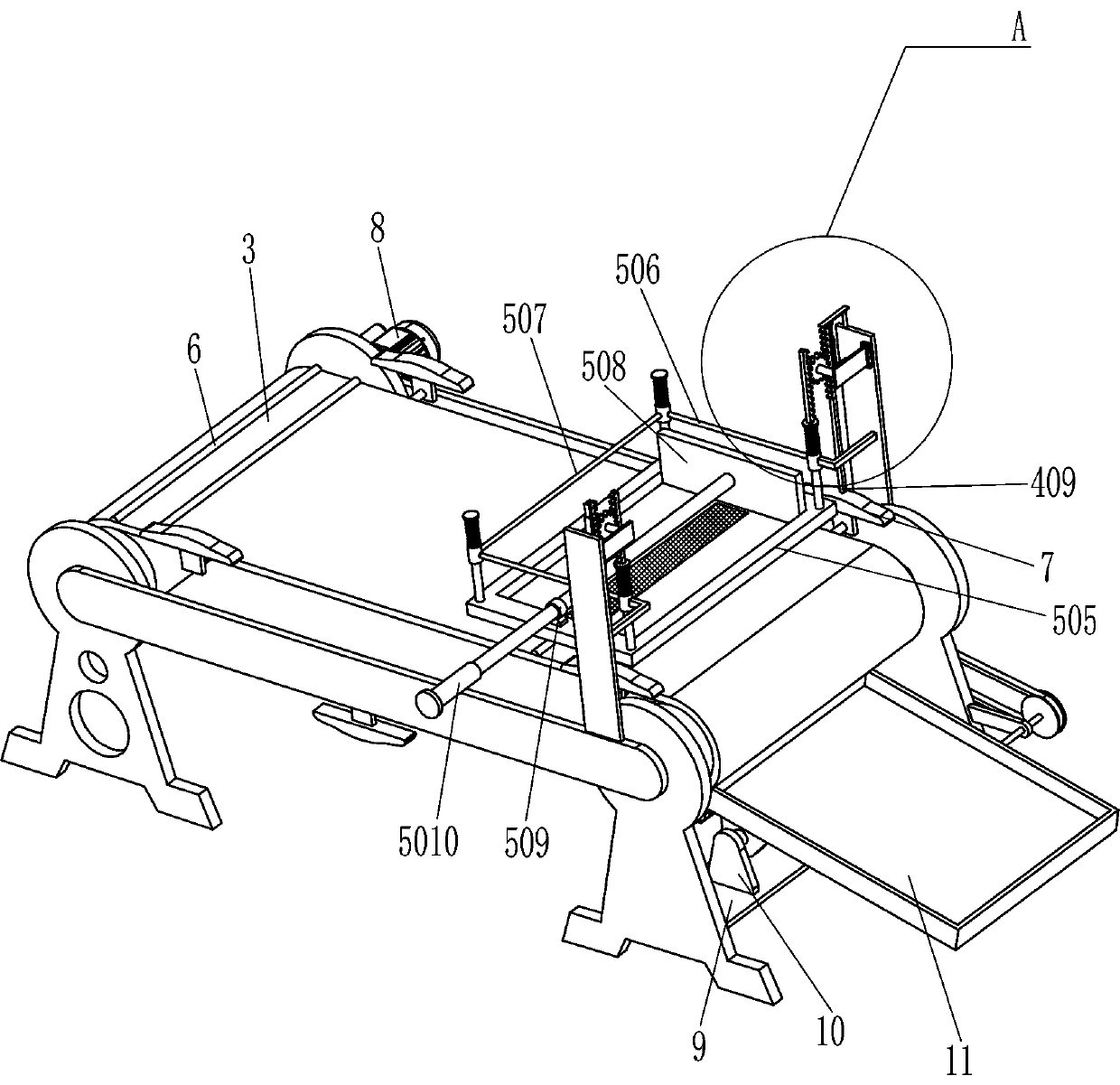

[0024] A hard box screen printing auxiliary packaging equipment, such as Figure 1-5 As shown, it includes base 1, driving roller 2, conveying steel belt 3, pushing device 4, silk screen device 5, rubber strip 6, push plate 7, gear motor 8, T-shaped plate 9, mounting seat 10, and receiving frame 11 And support base 12, all rotation is provided with driving roller 2 between the front and back both sides base 1, is wound with conveying steel belt 3 on the left and right sides driving roller 2, and left side base 1 outside upper part is symmetrically provided with propelling device 4, front and back two A screen printing device 5 is arranged between the side pushing devices 4, three pairs of rubber strips 6 are evenly spaced on the surface of the transmission steel belt 3, and three pairs of push plates 7 are evenly spaced on the sides of the transmission steel belt 3, and the push plates 7 are located on the corresponding rubber strips 6. The front part of the base 1 on the left...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 5-6 As shown, it also includes a second mounting plate 13, a rotating shaft 14, a cam 15 and a drive assembly 16. The left front base 1 is provided with a second mounting plate 13 at the lower left side of the base 1, and a rotating shaft 14 is provided in the second mounting plate 13 for rotation. Rotating shaft 14 rear end is provided with cam 15, and cam 15 contacts with material receiving frame 11 bottoms, and rotating shaft 14 front end is provided with driving assembly 16, and the upper end of driving assembly 16 is connected with the output shaft on the reduction motor 8.

[0032] Also include sliding seat 17, the second compression spring 18, moving bar 19 and pressing plate 20, the bottom side of material receiving frame 11 right is provided with sliding seat 17 symmetrically front and back, all sliding type is provided with moving bar 19 in the sliding seat 17, slides The inner bottom of the seat 17 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com