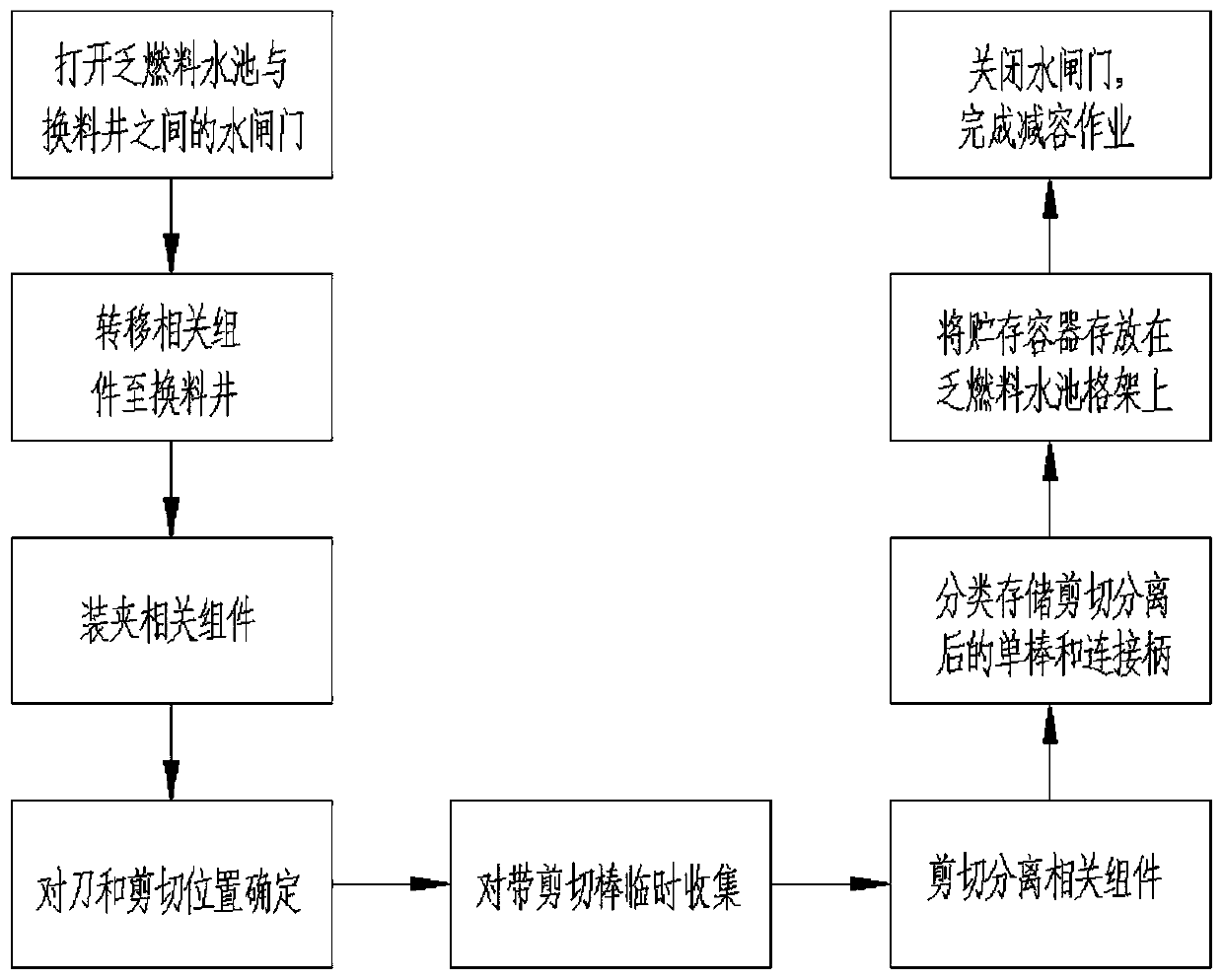

Underwater vertical volume shrinkage treatment method and device for fuel-related components

A processing device and processing method technology, applied in nuclear engineering, radioactive purification and other directions, can solve the problems of inability to flip components to a horizontal state, large cross-sectional size requirements of the shrinking site, and small tank size, so as to avoid leakage of radioactive substances. , Reduce the demand of the site, the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

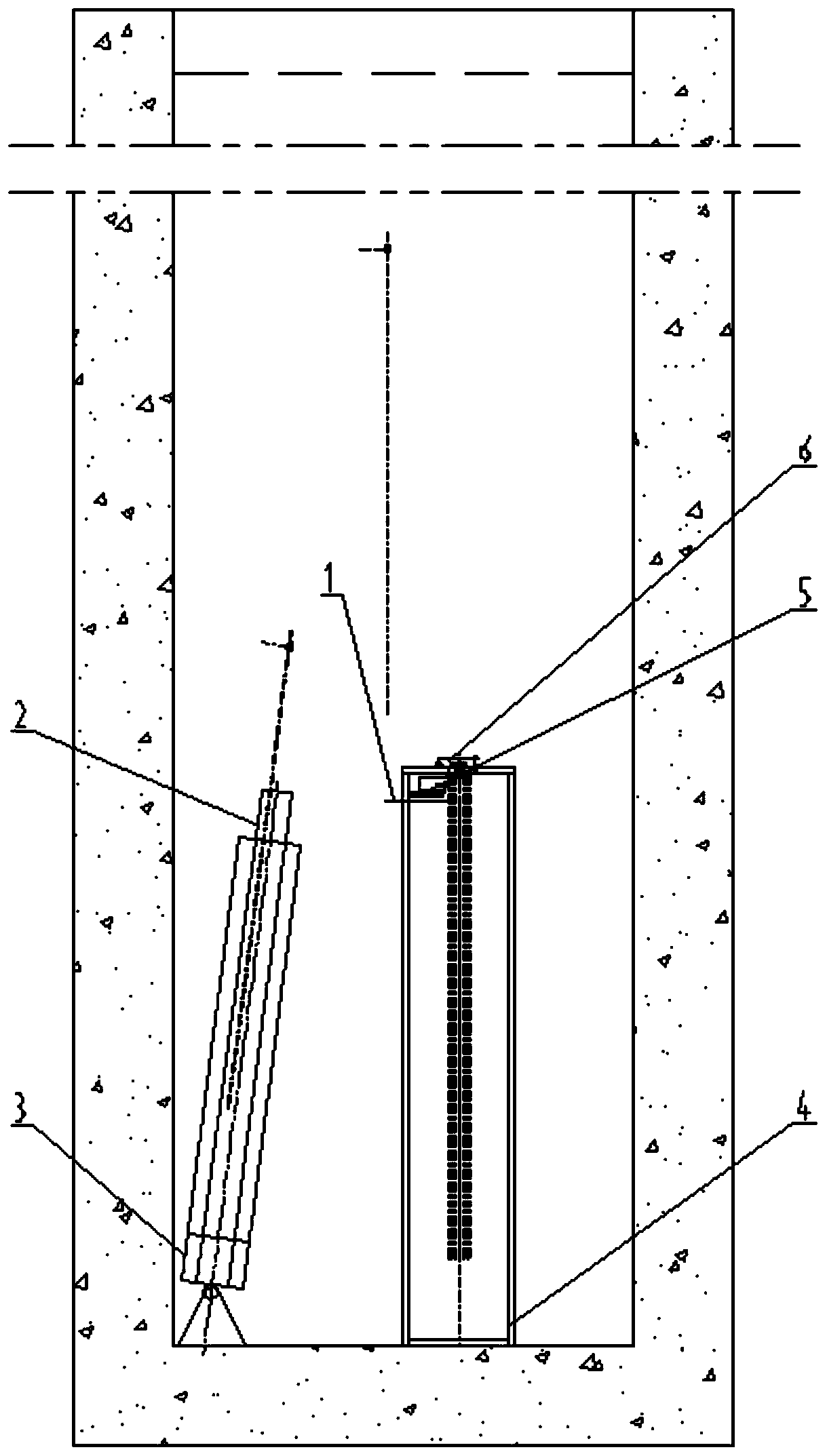

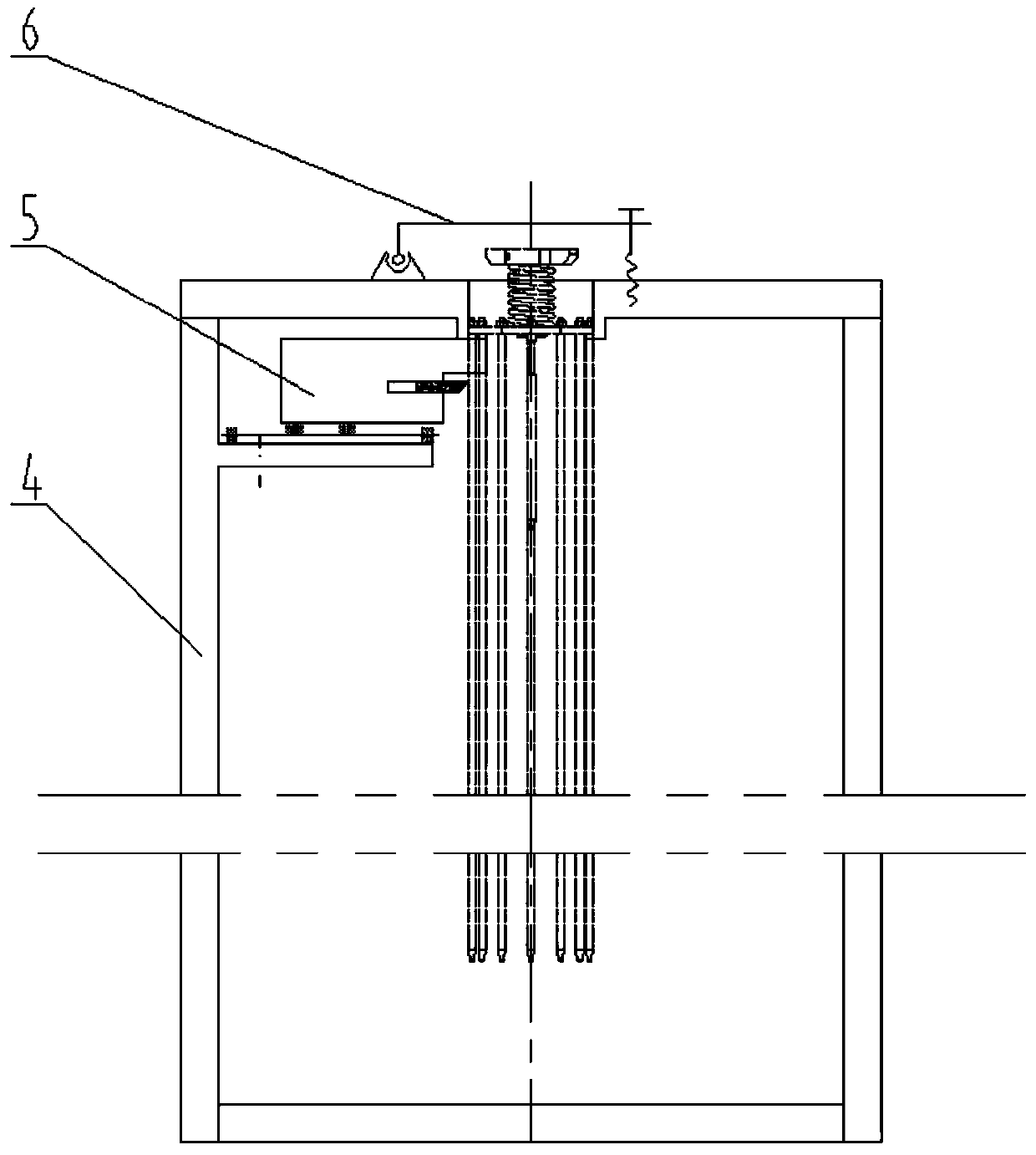

[0062] like figure 2 , image 3 As shown, an underwater vertical shrinkage treatment device for fuel-related components includes a tanking well, a storage rack 4, a shearing device 5, a clamping device 6, and a storage container 2, wherein the tanking well is set in the spent fuel pool and control the transfer of fuel-related components through the water gate between the canning well and the spent fuel pool; fill the canning well with water so that the water surface in the canning well is level with the water surface in the spent fuel pool, A storage rack 4 is installed at the bottom of the tank well, and a clamping device 6 is installed on the upper surface of the storage rack 4. The fuel-related components are moved to the tanking well by the exhaust crane, and placed vertically inside the storage rack 4, and the clamping device 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com