Inventory path optimization method and device

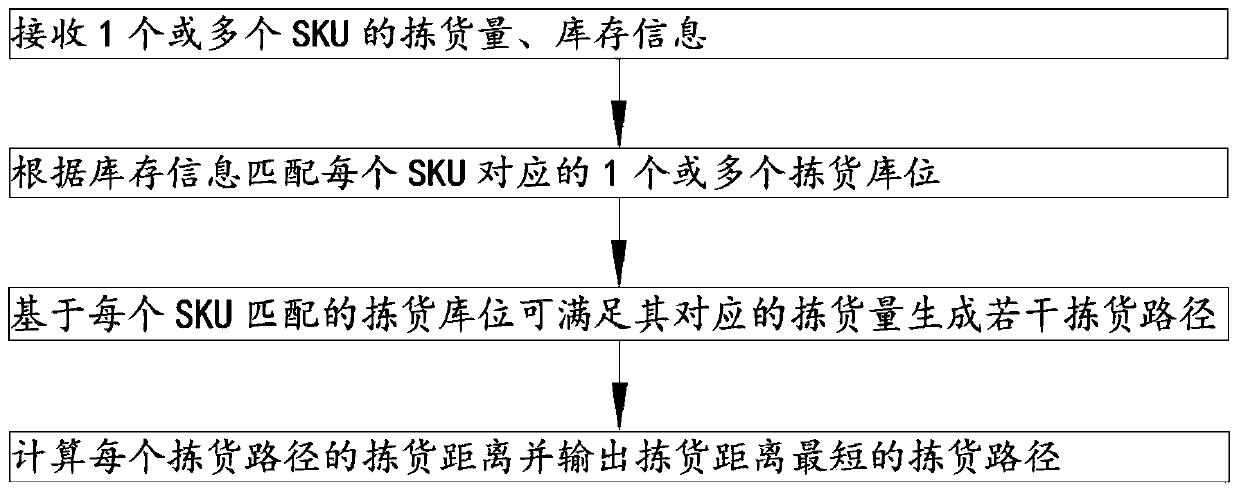

A route optimization and inventory technology, applied in the field of warehousing, can solve the problems of low overall efficiency, difficulty in meeting different SKUs, and difficulty in effectively utilizing cargo space, etc., to achieve effective guidance, improve overall efficiency, and meet business requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An inventory path optimization device in this embodiment includes:

[0048] The information receiving unit is configured to receive the picking quantity and inventory information of one or more SKUs. The inventory information refers to the corresponding relationship between the inventory location and the SKU type and inventory amount. For example, there are N types of SKUs: 1, 2,… ,N,SKU k The location set is L k , the inventory quantity on the i-th location is c ki ,i∈L k , the required picking quantity is p k , the present embodiment is preferably real-time inventory information, 1, real-time inventory information can also come from other modules such as random replenishment in addition to the location placement.

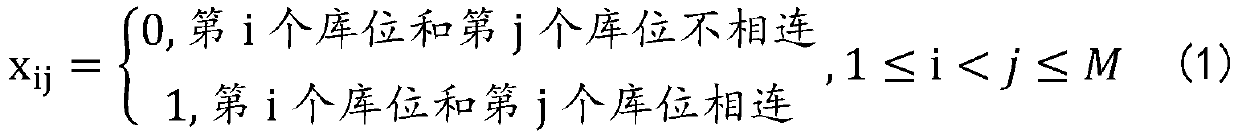

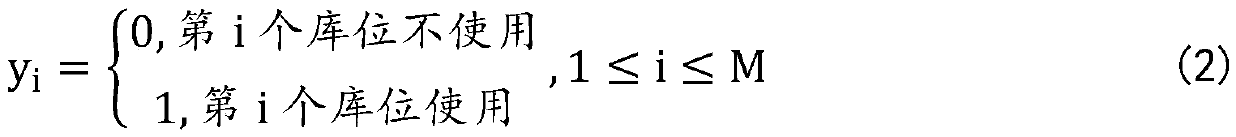

[0049] The information generation unit is configured to match one or more picking locations corresponding to each SKU according to the inventory information, specifically including: an inventory quantity acquisition module configured to obtain the locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com