Asphalt pavement maintenance method and vehicle additionally-hung forward-pushing type road roller

A technology of asphalt pavement and road roller, applied in the direction of roads, roads, road repairs, etc., can solve problems such as low efficiency, high cost, waste of resources, etc., and achieve the effects of reducing costs, avoiding waste, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

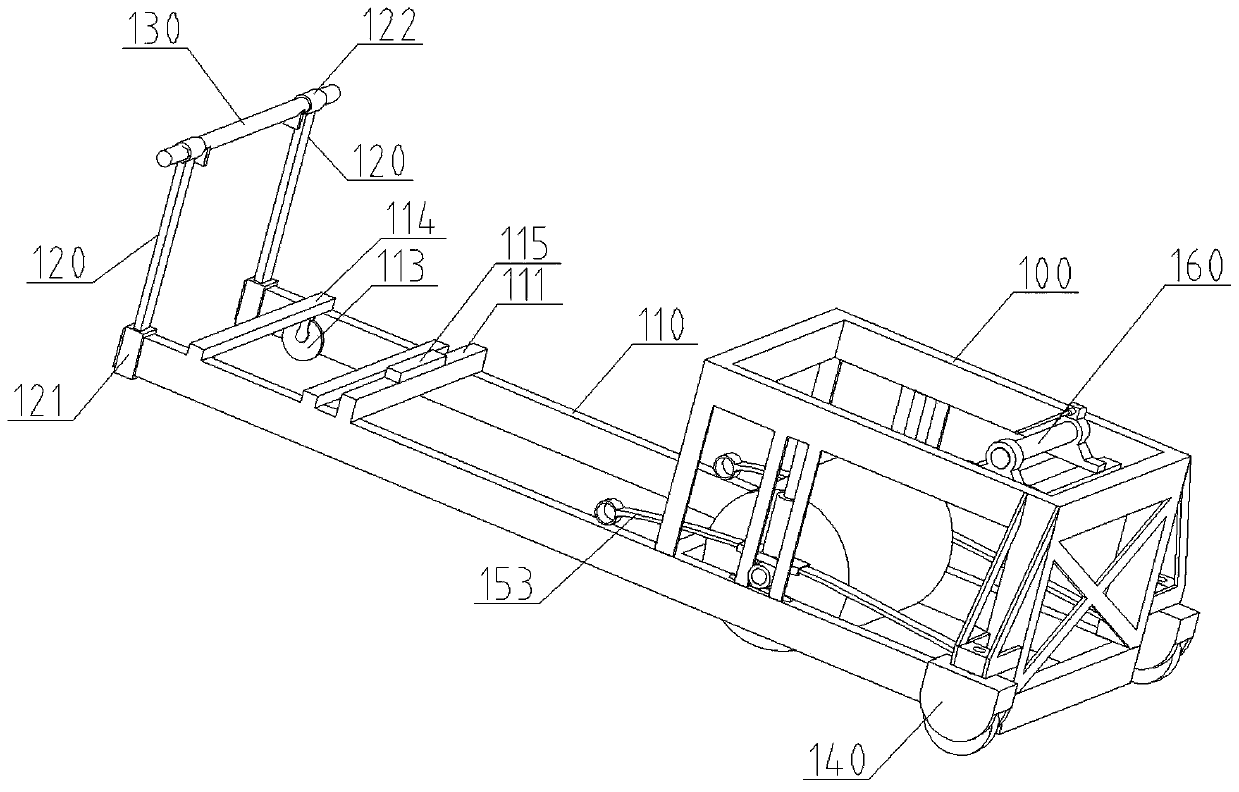

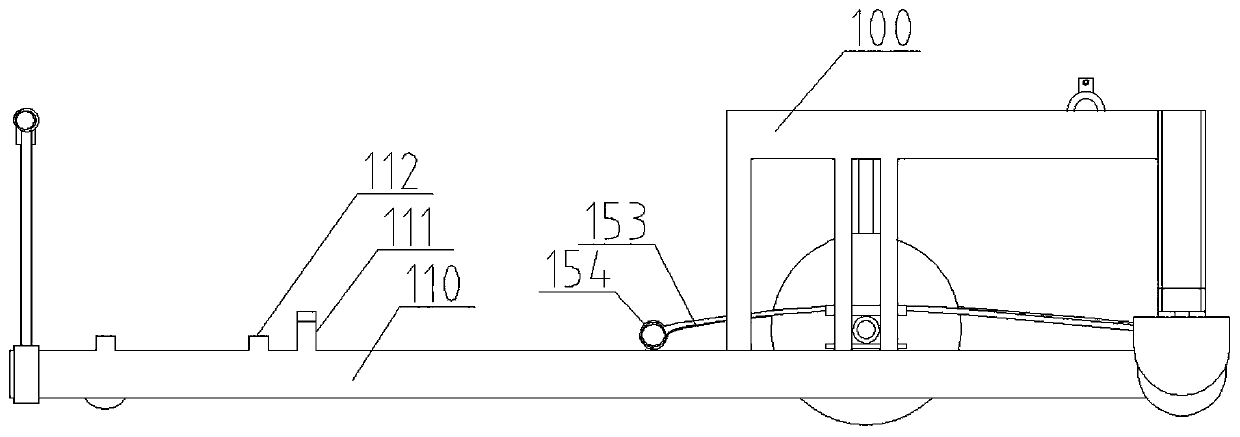

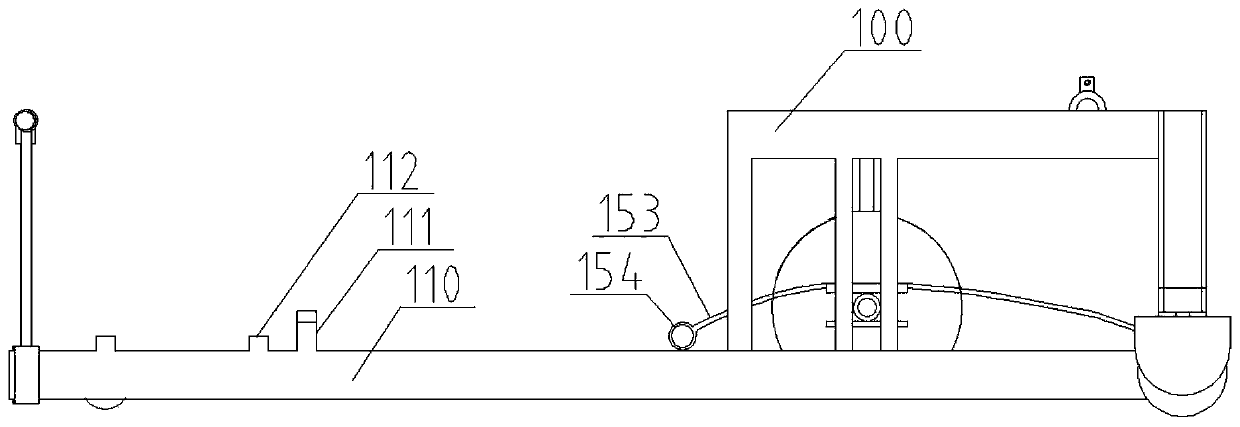

[0040] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

[0041] The invention provides a kind of asphalt pavement maintenance method, comprises the following steps:

[0042] S1. Asphalt prefabricated square blocks. Press the remaining material after the asphalt pavement is laid into a rated size square block with a hydraulic press and a mold. The length of the square block is: 300mm, the width: 300mm, and the thickness: 45mm;

[0043] S2, square plate storage, the pressed square plate is sealed and stored with a plastic film;

[0044] S3. Clean up pits and cracks, estimate the number of square plates used according to the size of pits or cracks, and dig out square trenches of appropriate size;

[0045] S4. Spray asphalt-bonded oil, evenly spray asphalt-bonded oil on the inner wall and bottom of the squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com