Sheet type silencer

A muffler and chip technology, which is applied in the direction of sound-emitting devices, instruments, and noise suppression, can solve the problems of lack of mufflers, etc., and achieve the effects of reducing flow loss, facilitating absorption, and benefiting low-frequency sound absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

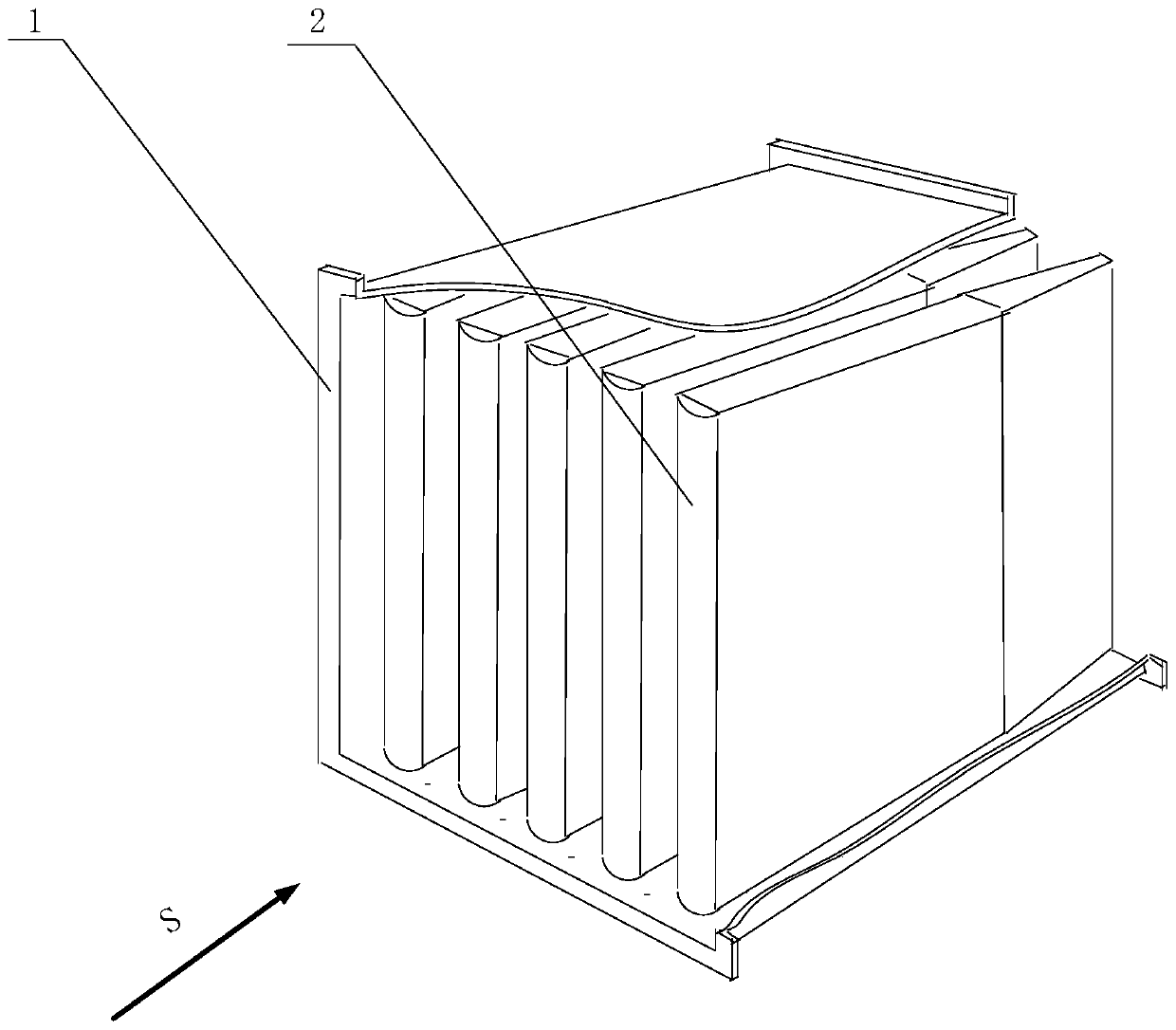

[0044] combine Figure 1-Figure 3 Shown, a kind of chip muffler, it comprises:

[0045] mufflers, and

[0046] The outer casing of the muffler 1, the outer casing 1 of the muffler is suitable for accommodating at least two sound-absorbing sheets at intervals, an air flow channel is formed between the two sound-absorbing sheets, and the outer casing 1 of the muffler is made of metal or hard plastic Support to ensure the working stability of the internal muffler;

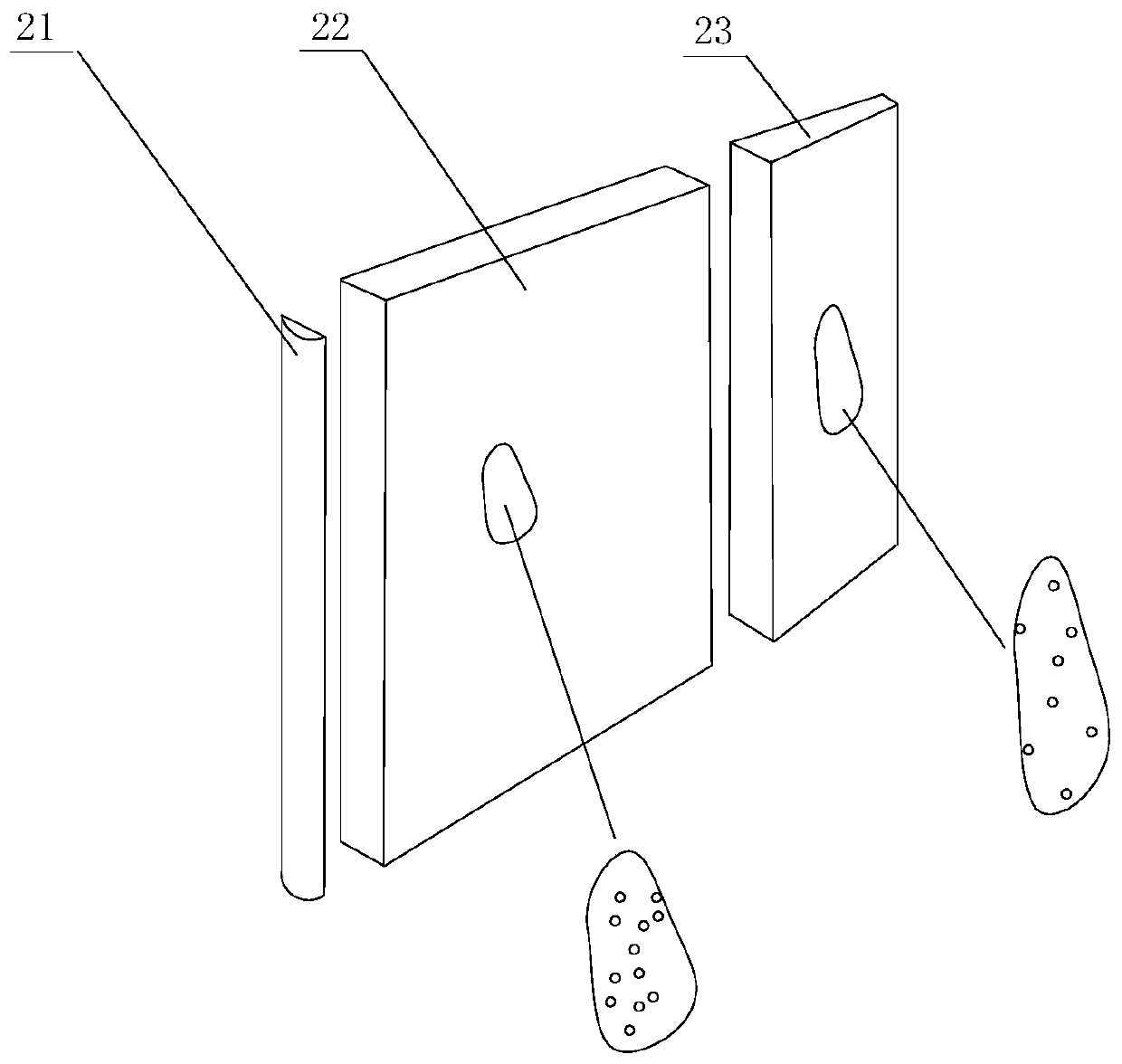

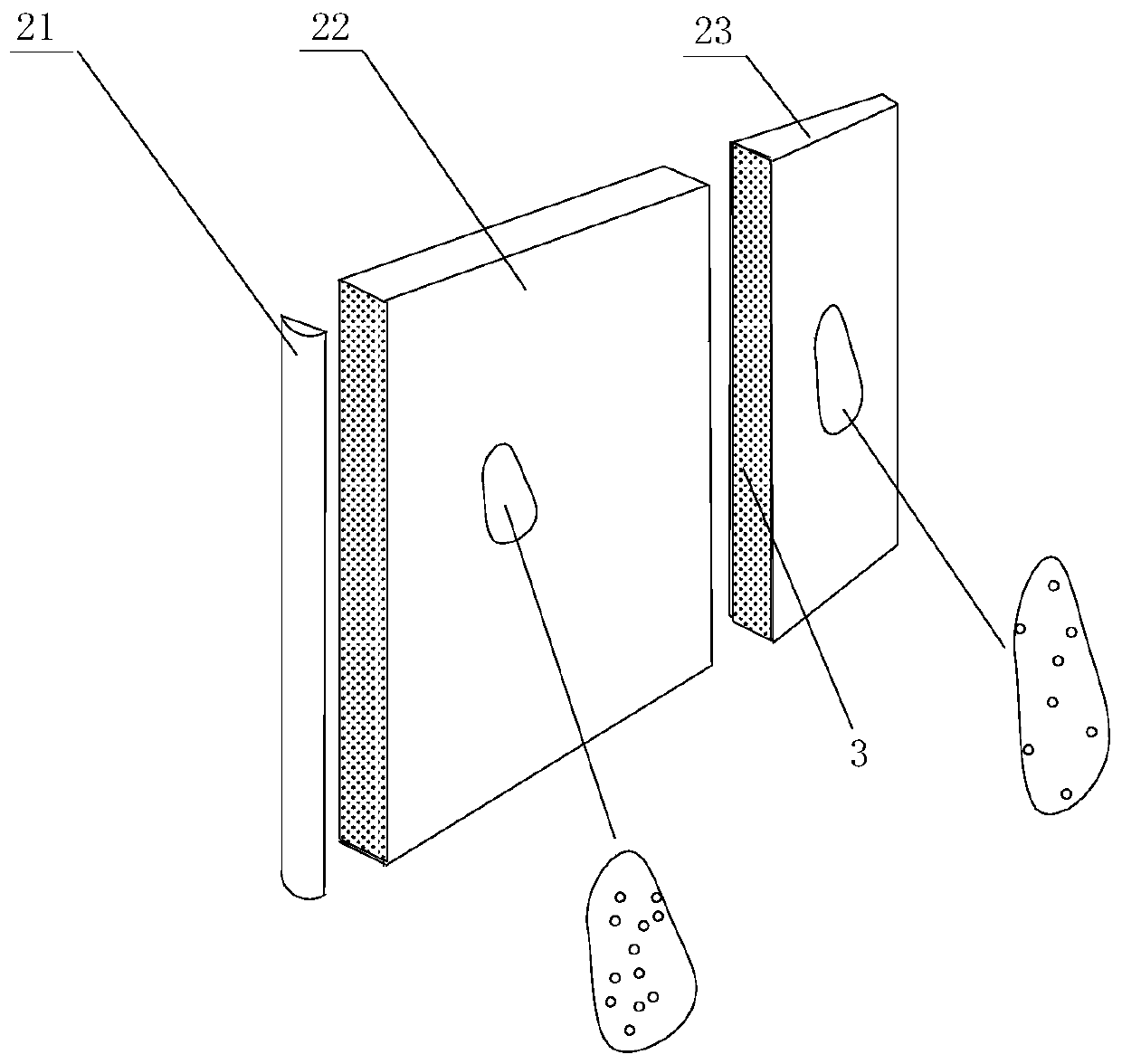

[0047] The sound-absorbing sheet includes:

[0048] The sound-absorbing sheet housing 2, which is at least partly made of perforated plates; and

[0049] sound-absorbing material 3, the sound-absorbing material 3 is evenly filled inside the sound-absorbing sheet shell 2;

[0050] The sound-absorbing sheet shell 2 is composed of at least two kinds of perforated plates with different perforation rates.

[0051] It should be noted that the perforation rate refers to the ratio of the sum of perforation areas to the t...

Embodiment 2

[0077] In order to prove that the noise-absorbing sheet provided by the present invention and the corresponding sheet-type muffler have a better noise-absorbing effect compared with the traditional noise-absorbing structure, a detailed description will be given below through a control experiment.

[0078] For the convenience of expression, the sound-absorbing sheet provided by the present invention is referred to as the sound-absorbing sheet hereinafter, and the sheet-type muffler provided by the present invention is referred to as the present muffler for short.

[0079] combine Figure 5 As shown, as a comparison, the muffler without tapered panels is used as the reference muffler, and the muffler corresponding to the reference muffler, which has a uniform channel front and back along the airflow direction S, and a given pressure loss is defined as the reference muffler. When designing this muffler, ensure that the thickness of the parallel part of this muffler is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com