Method for preparing flotation collector from ether mixture

A mixture and collector technology, applied in flotation, solid separation, etc., can solve the problems of high cost, high chemical consumption, and uneconomical low-rank coal flotation, and achieve easy access, wide sources, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

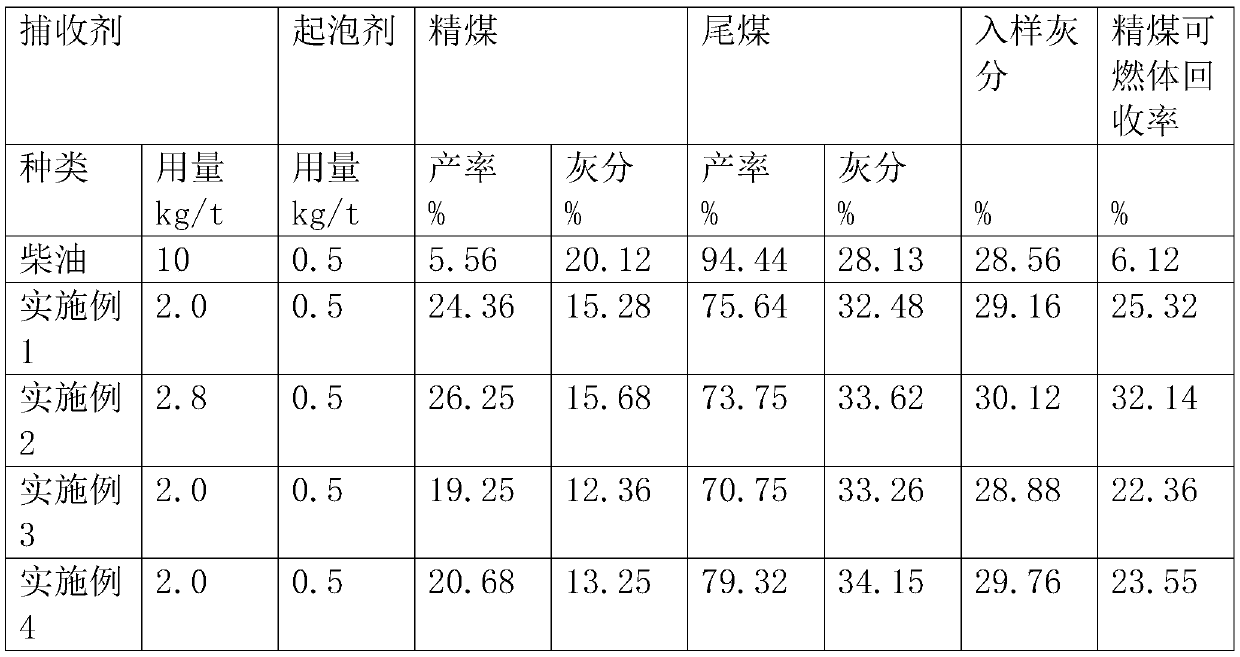

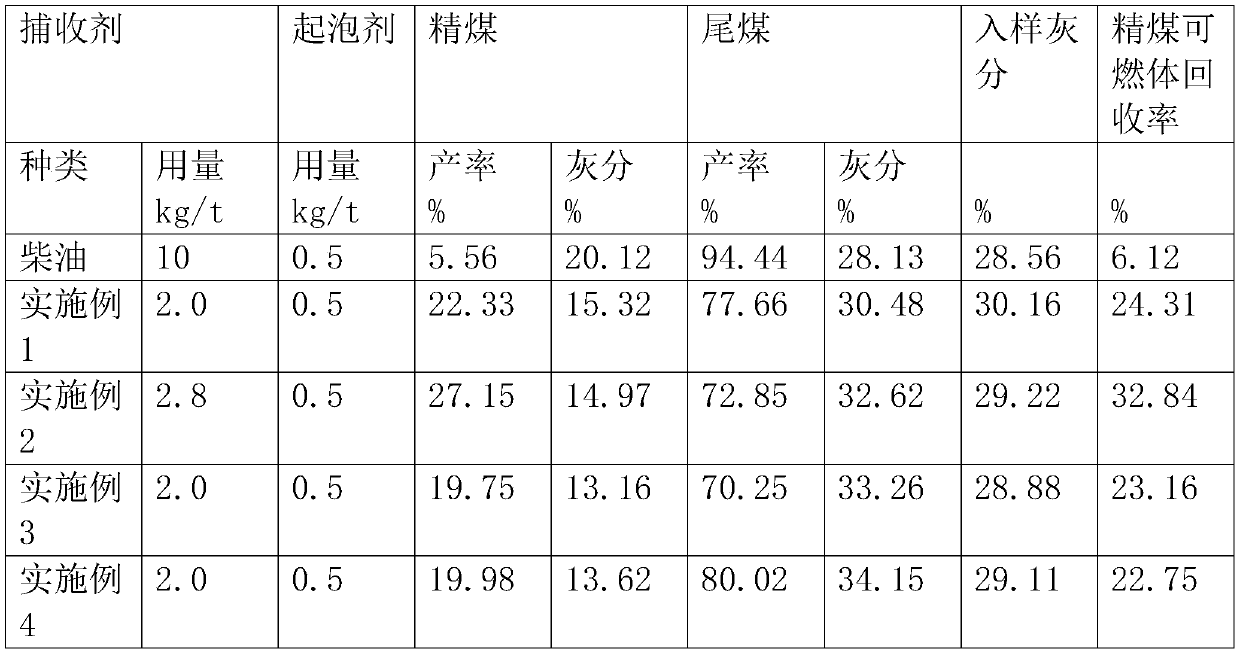

Examples

Embodiment 1

[0021] A kind of ether mixture prepares the method for flotation collector, comprises the following steps:

[0022] (1), choose the hydrocarbon oil of mass ratio 46%, the mixed ether of 48%, the accelerator of 6%.

[0023] The hydrocarbon oil is selected from C10-C16 hydrocarbon oil, and diesel oil is selected in this embodiment.

[0024] The mixed ether is a mixture of dimethoxy dimethyl ether and trimethoxy dimethyl ether, and the mass ratio of dimethoxy dimethyl ether to trimethoxy dimethyl ether is 20:3.

[0025] Accelerator selects diethylene oxide.

[0026] (2), each component in step (1) is added in the mixing tank respectively, utilize stirring shaft to stir to make it mix evenly, stirring time 10 minutes;

[0027] (3) After the stirring is completed, the collector is obtained.

Embodiment 2

[0029] A kind of ether mixture prepares the method for flotation collector, comprises the following steps:

[0030] (1), choose the hydrocarbon oil of mass ratio 50%, the mixed ether of 45%, the accelerant of 5%.

[0031] The hydrocarbon oil is selected from C10-C16 hydrocarbon oil, and diesel oil is selected in this embodiment.

[0032] The mixed ether is a mixture of dimethoxy dimethyl ether and trimethoxy dimethyl ether, and the mass ratio of dimethoxy dimethyl ether to trimethoxy dimethyl ether is 20:4.

[0033] Accelerator selects diethylene oxide.

[0034] (2), each component in step (1) is added in the mixing tank respectively, utilize stirring shaft to stir to make it mix evenly, and stirring time is 13 minutes;

[0035] (3) After the stirring is completed, the collector is obtained.

Embodiment 3

[0037] A kind of ether mixture prepares the method for flotation collector, comprises the following steps:

[0038] (1), choose the hydrocarbon oil of mass ratio 45%, the mixed ether of 50%, the accelerator of 5%.

[0039] The hydrocarbon oil is selected from C10-C16 hydrocarbon oil, and diesel oil is selected in this embodiment.

[0040] The mixed ether is a mixture of dimethoxy dimethyl ether and trimethoxy dimethyl ether, and the mass ratio of dimethoxy dimethyl ether to trimethoxy dimethyl ether is 20:3.

[0041] Accelerator selects diethylene oxide.

[0042] (2), each component in step (1) is added in the mixing tank respectively, utilizes stirring shaft to stir to make it mix evenly, stirring time 12 minutes;

[0043] (3) After the stirring is completed, the collector is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com