Pressing-type anti-theft opened cap and bottle

A press-type, open-cap technology, applied in bottle filling, bottle/container caps, and capping containers tightly with caps, etc., can solve problems such as unsanitary and inconvenience, and achieve the effect of ensuring hygiene conditions and simple and quick operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

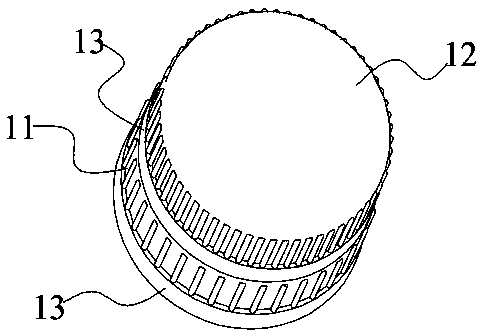

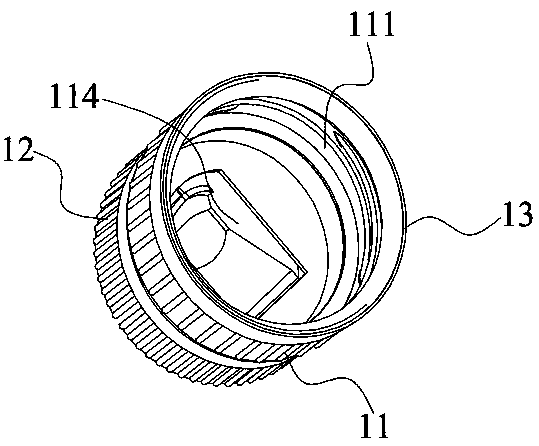

[0036] One embodiment of the present invention is a push-type anti-theft opening cover, the structure of which is as attached figure 1 And attached figure 2 shown. The push type anti-theft opening cover 10 includes a cover body 11 , a secondary sealing cover 12 and an anti-theft ring 13 .

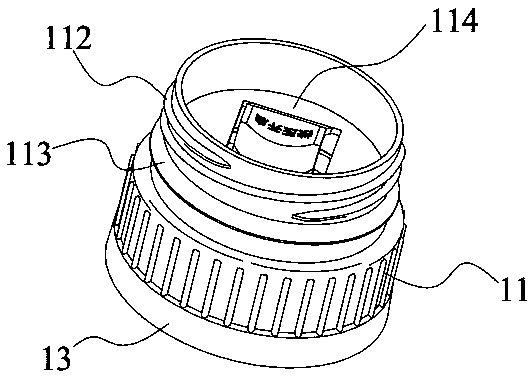

[0037] Specifically, the cover body 11 is entirely made of PP material. The upper and lower ends of the cover body 11 are open, and an internal thread 111 is formed on the inner side of the lower part of the cover body 11 , and an external thread 112 and a collar 113 are formed on the outer wall of the upper part of the cover body 11 . The size of one end of the cap body 11 where the external thread 114 is located is consistent with the size of the mouth of the bottle body 20 . A breaking structure 114 is provided inside the cover body 11 , and the breaking structure 114 is connected to the inner side of the closed end of the cover body 11 . When the sealing film at the mouth of the bo...

Embodiment 2

[0042] One embodiment of the present invention is a push-type anti-theft opening cover, the structure of which is as attached Figure 5 shown. The push type anti-theft opening cover 10 includes a cover body 11 , a secondary sealing cover 12 and an anti-theft ring 13 .

[0043] Specifically, the cover body 11 is made of PP material as a whole, and its structure is as attached image 3 And attached Figure 4 . The upper and lower ends of the cover body 11 are open, and an internal thread 111 is formed on the inner side of the lower part of the cover body 11 , and an external thread 112 and a collar 113 are formed on the outer wall of the upper part of the cover body 11 . The size of one end of the cap body 11 where the external thread 114 is located is consistent with the size of the mouth of the bottle body 20 . A breaking structure 114 is provided inside the cover body 11 , and the breaking structure 114 is connected to the inner side of the closed end of the cover body 11...

Embodiment 3

[0050] One embodiment of the present invention, a kind of bottle, its structure is as attached Figure 6 shown. The bottle includes a push type anti-theft opening cap 10, a sealing film and a bottle body 20.

[0051] Specifically, the push-type anti-theft opening cover 10 includes a cover body 11 , a secondary sealing cover 12 and an anti-theft ring 13 . The cover body 11 is entirely made of PP material. The upper and lower ends of the cover body 11 are open, and an internal thread 111 is formed on the inner side of the lower part of the cover body 11 , and an external thread 112 and a collar 113 are formed on the outer wall of the upper part of the cover body 11 . The size of one end of the cap body 11 where the external thread 114 is located is consistent with the size of the mouth of the bottle body 20 . A breaking structure 114 is provided inside the cover body 11 , and the breaking structure 114 is connected to the inner side of the closed end of the cover body 11 . W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com