A packaging box for packaging the frame of the front door and window of a car

A packing box and car window technology, applied in the direction of packaging, transportation and packaging, bottle/can parts, etc., can solve the problems of high transportation cost, high cost, easy assembly error, etc., to increase the number of storage and load-bearing capacity Good, the effect of avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

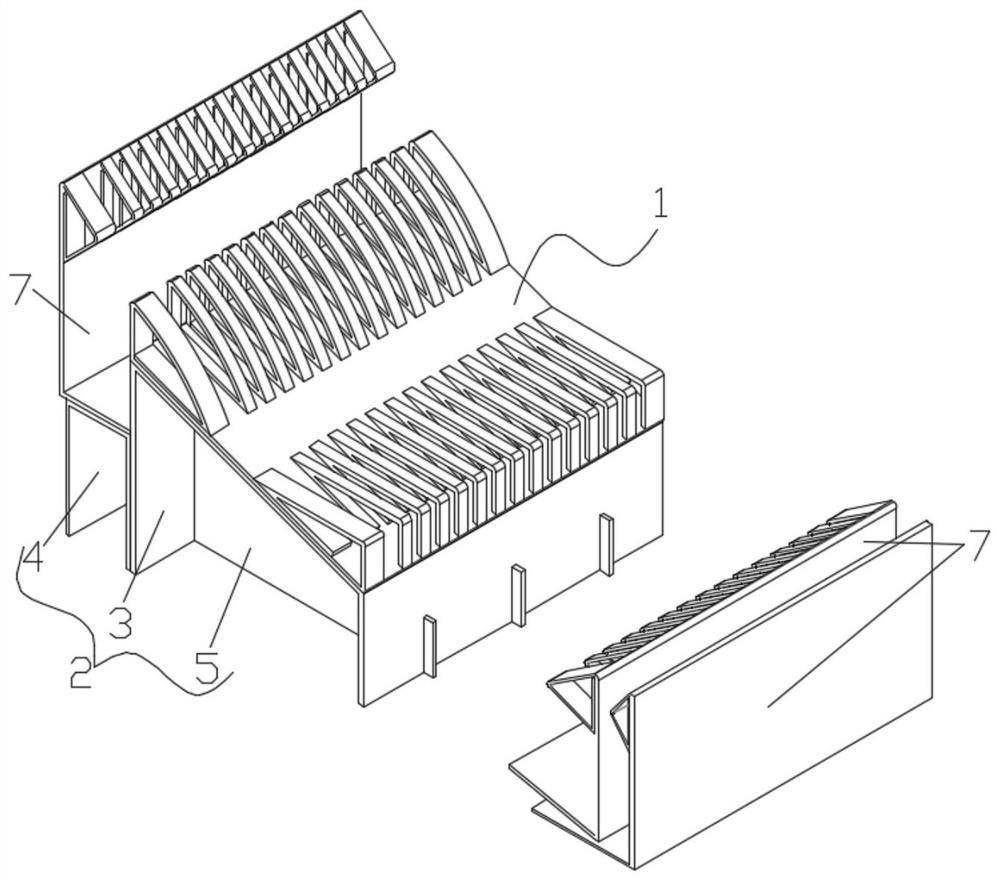

[0030] Such as Figure 1-6 As shown, a packaging box for packaging the front door window frame of an automobile includes a box body 1, a support seat 2 is placed on the inner bottom of the box body 1, a first positioning structure 6 is placed on the top of the support seat 2, and a support seat 2 is placed on the rear end. The second positioning structure 7 is also placed with two second positioning structures 7 away from the front end of the support base 2, and the two second positioning structures 7 are stacked on each other, and are opposite to the second positioning structure 7 placed at the rear end of the support base 2 .

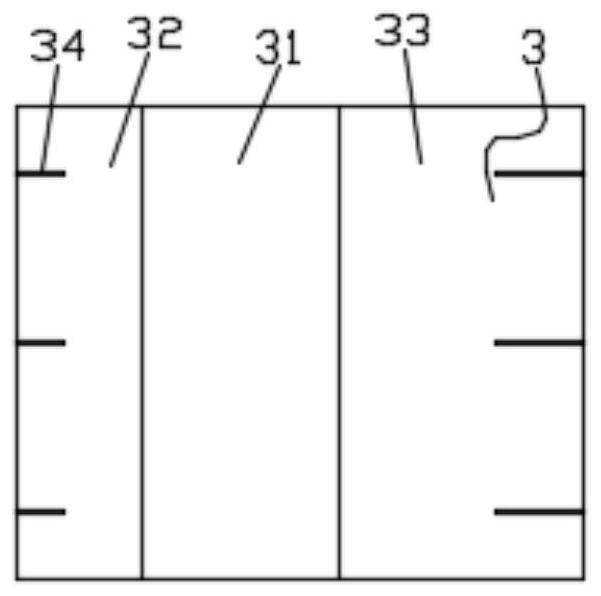

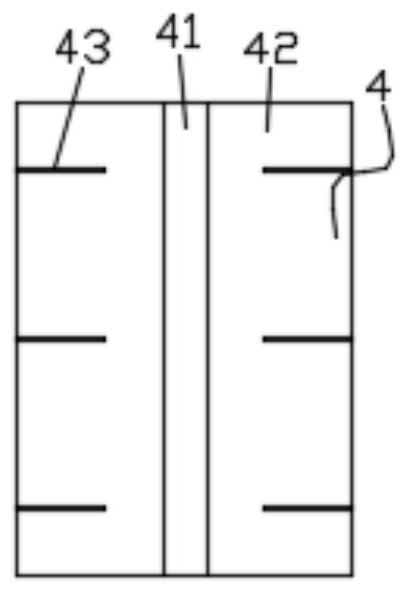

[0031] Preferably, the support seat 2 includes an inclined plate 3, a supporting plate 4 and a vertical plate 5, the inclined plate 3 is a three-section plate, the middle section of the inclined plate 3 is an inclined part 31, and one of the end sections is a short part 32, and the other One end section is a long part 33, the short part 32 of the inc...

Embodiment 2

[0042] The only difference from Embodiment 1 is that, preferably, the other end of the lower base plate 76 is connected with a lower extension plate 77, the specification of the lower extension plate 77 is consistent with the specification of the lower base plate 76, and the folding place between the vertical plate 71 and the lower base plate 76 is in line with that of the lower base plate 76. A buckle structure is provided between the lower extension plates 77 .

[0043] The lower base plate 76 is offset against the box body 1, and two plates overlapped can increase the friction force and prolong the service life.

[0044] Preferably, the buckle structure includes a protrusion 78 disposed on the outside of the lower extension plate 77 and a depression 79 disposed at the fold of the vertical plate 71 and the lower bottom plate 76, and the protrusion 78 and the depression 79 are engaged with each other.

[0045] Through the buckle structure, the lower bottom plate 76 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com