Paper box rapid gluing and forming machine

A glue forming machine and fast technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problem of slow glue application, and achieve the effect of reducing labor intensity, fast speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

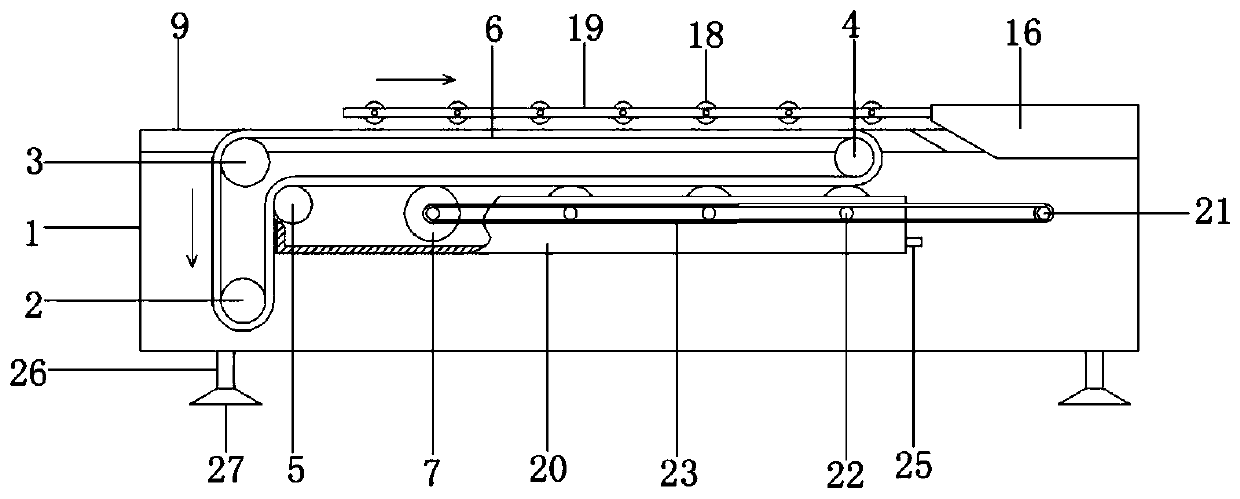

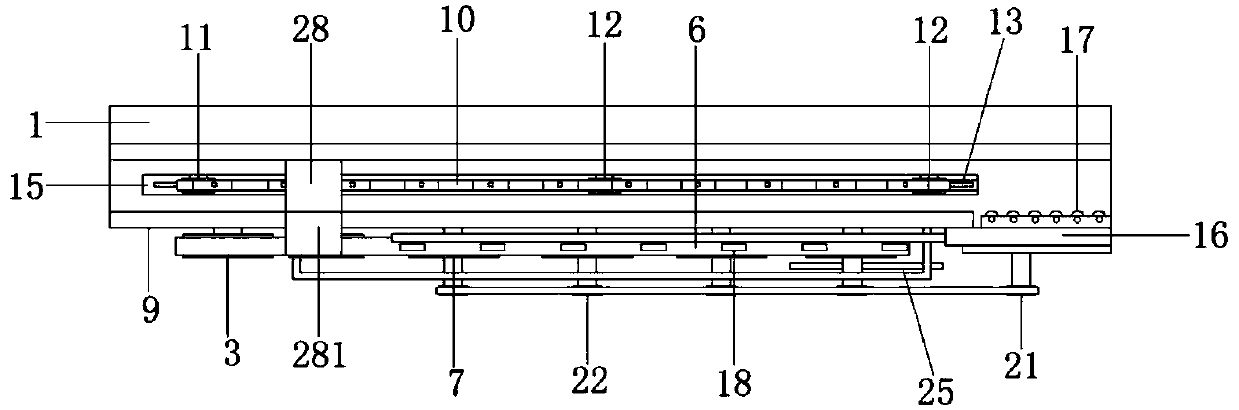

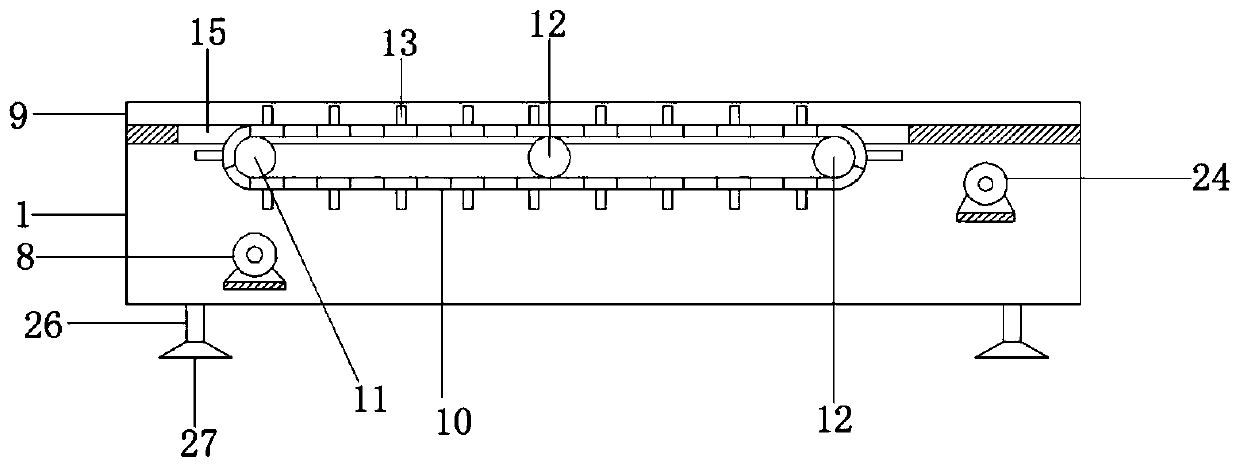

[0027] Such as Figure 1 to Figure 4 As shown, a carton 28 fast gluing forming machine includes a casing 1, a gluing mechanism and a chain rail transmission mechanism, and the gluing mechanism includes a driving wheel 2, a first track changing wheel 3, and a second track changing wheel 4. The third track-changing wheel 5, the coating belt 6 and several glue-coating wheels 7, the driving wheel 2 is connected with the transmission shaft of the first motor 8 arranged in the casing 1, and the first track-changing wheel 3. The second track changing wheel 4, the third track changing wheel 5 and the glue coating wheel 7 are arranged on the outer wall of the casing 1, the first track changing wheel 3 is located directly above the driving wheel 2, and the second track changing wheel 4 At the same horizontal position as the first track changing wheel 3, the third track changing wheel 5 is located below the first track changing wheel 3 and the second track changing wheel 4, and the coate...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 , figure 2 with image 3 As shown, the chain rail transmission mechanism includes a guide rail plate 9, a transmission chain 10, a driving gear 11, several driven gears 12, a vertical baffle plate 13 and a second motor, and the guide rail plate 9 is arranged in parallel with two On the casing 1, the casing 1 between the guide rail plates 9 is provided with a through groove 15, and the driving gear 11 and the driven gear 12 are respectively arranged on the first rotating roller and the second rotating roller, and are located in the through groove 15 Between, one end of the first rotating roller is connected to the transmission shaft of the second motor, and the other end is connected to the inner wall of the casing 1, the second motor is arranged in the casing (not shown in the drawings), and the first The two ends of the two rotating rollers are rotatably connected with the inner wall. The transmission chain is connected to...

Embodiment 3

[0033] On the basis of Example 1, such as figure 2As shown, the inner wall of the bending plate 16 is rotatably provided with tightening rollers 17, several in number, which just accept the end of the through groove 15, and the inner side of the tightening rollers 17 is in the same horizontal direction as the inner wall of the guide rail plate 9 in the horizontal direction. . After the carton 28 is transported to the end of the through groove 15, it is pushed to the take-up roller 17 by the carton 28 transported from the back. Because there is a certain distance between the cartons 28 that are glued before and after, there is also a certain time difference, so The carton 28 located at the tightening roller 17 will stay for a period of time, and the inner side of the tightening roller 17 is in the same horizontal direction as the inner wall of the guide rail plate 9 in the horizontal direction, and the distance between the guide rail plates 9 must be equal to the carton 28 whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com