Method for adjusting tooling and shaping steel plate depressions on the hull surface

A technology for hull and tooling, applied in the direction of ships, etc., can solve the problems of unfavorable interior decoration, insufficient safety, reversely dented steel plate surface, etc., and achieve the effect of convenient use and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

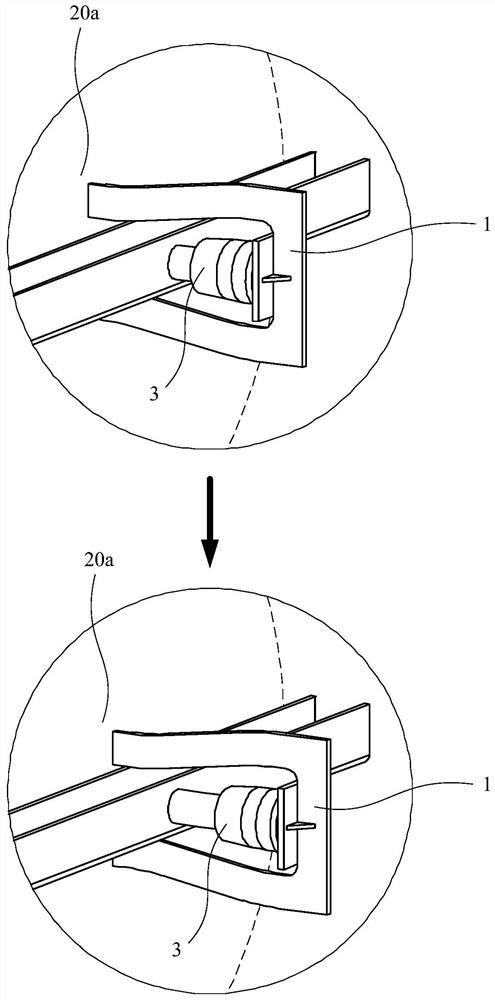

[0049] Such as figure 1 with figure 2 As shown, the present invention provides an adjustment tool for adjusting the steel plate depression 20a on the hull surface 20 , the adjustment tool specifically includes a first fixed part 1 , a second fixed part 2 and a movable part 3 . Wherein, the first fixed part 1 has a fixed end 1a (see image 3 ), the fixed end 1a is used to be fixed at the position of the depression 20a on the surface of the hull 20, the second fixed part 2 is directly arranged on the surface of the hull 20, which is specifically a long strip structure, and the two ends of the second fixed part 2 respectively abut against On both side edges 20b of the recess 20a, the second fixed part 2 is located between the hull surface 20 and the supporting surface of the first fixed part 1, while the movable part 3 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com