Glue storage mechanism of automatic dispensing equipment for cosmetic processing

An automatic glue dispensing and cosmetics technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of damage to the storage mechanism, glue residue, high glue temperature, etc., and achieve the effect of rapid discharge and prevention of glue residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

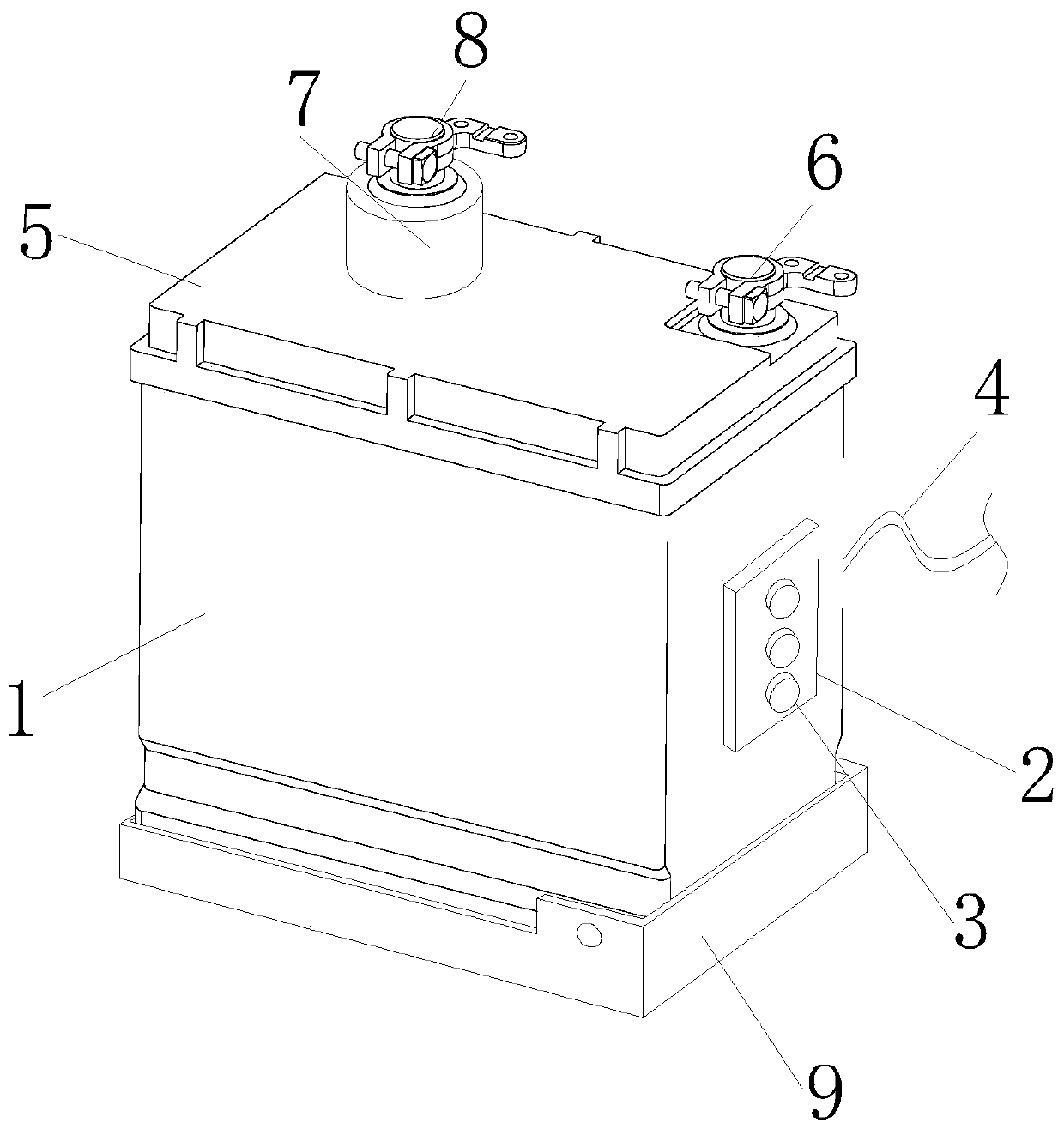

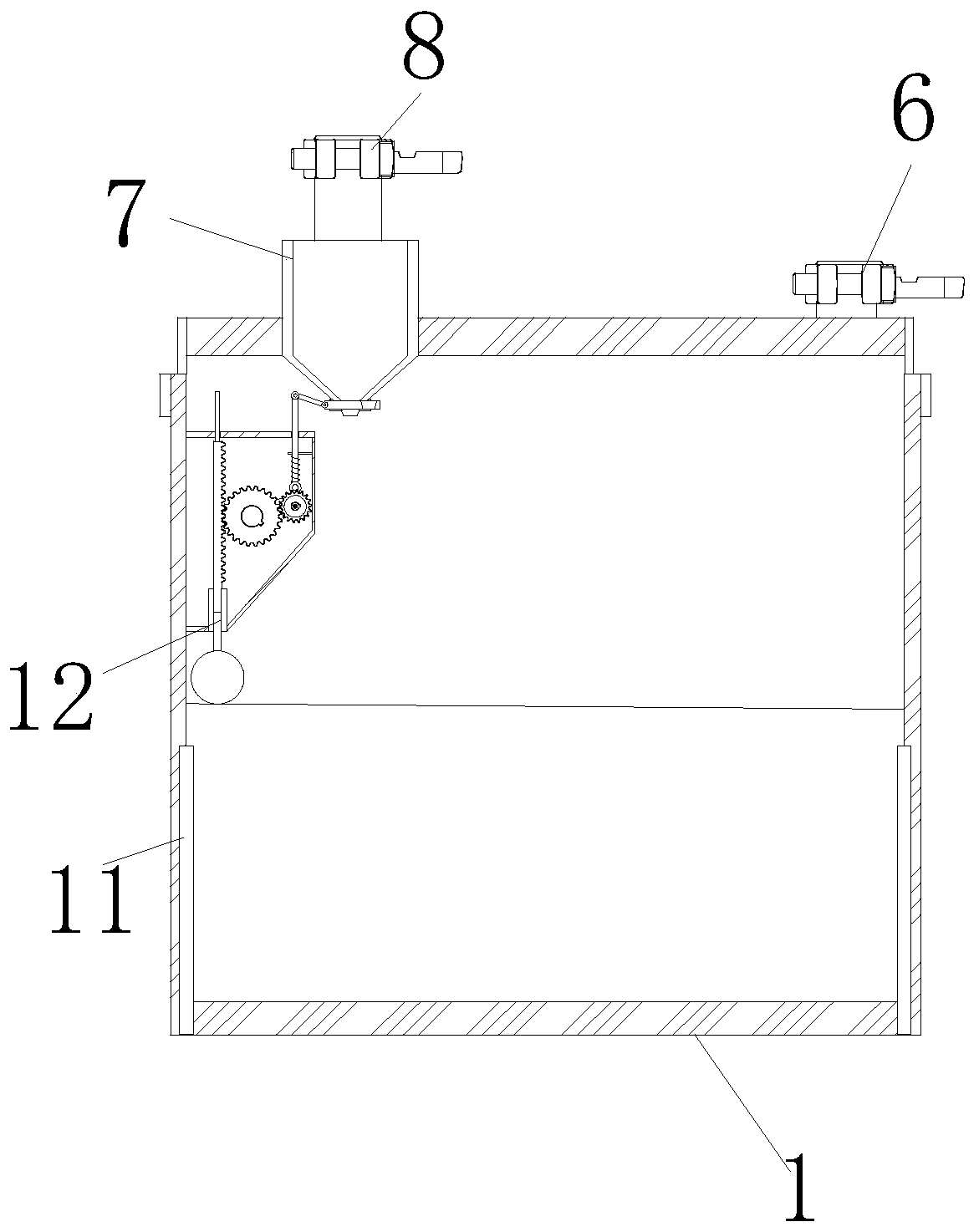

[0033] see figure 1 , figure 2 and image 3 , the present invention provides a glue storage mechanism for automatic dispensing equipment for cosmetics processing through improvement, including a storage frame 1, a top cover 5, a feeding pipe 8, a bottom frame 9, a heating plate 11, a tilting mechanism 10 and a connecting rod The discharge device 12, the right end of the storage frame 1 is provided with a control panel 2, the right end of the control panel 2 is equipped with a button 3, the rear end of the storage frame 1 is fixed with a power lead 4, the storage frame 1 is fixedly connected to the bottom of the top cover 5, and the top cover 5 is connected to the pumping The bottom edge of the tube 6 is seamlessly connected, the top cover 5 is fixedly connected to the lower end of the storage tube 7, the tilting mechanism 10 is installed and fixed on the lower left end inside the bottom frame 9, the connecting rod discharge device 12 is fixedly connected to the upper left en...

Embodiment 2

[0040] The present invention provides a glue storage mechanism for automatic glue dispensing equipment for cosmetics processing through improvement. The role of installation and fixation, the interior of the storage tube 7 is hollow, and the lower end of the storage tube 7 is funnel-shaped, which is beneficial to discharge the glue. After the sealing block 12364 is moved to the left, the discharge hole 12365 is located at the opening of the lower end of the storage tube 7. The lower side is beneficial to discharge the glue.

[0041] The present invention provides a glue storage mechanism of automatic glue dispensing equipment for cosmetics processing through improvement, and its working principle is as follows;

[0042] First, before use, place the glue storage mechanism of the automatic glue dispensing equipment for cosmetics processing horizontally, so that the bottom frame 9 can fix and support the mechanism;

[0043] Second, when in use, connect the external power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com