Leather zipper pull packaging machine

A packaging machine and leather technology, applied in the field of machinery, can solve the problems of difficulty in grasping the amount of glue applied, affecting the pass rate, affecting productivity, etc., and achieve the effects of reducing odor volatilization, improving the working environment, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

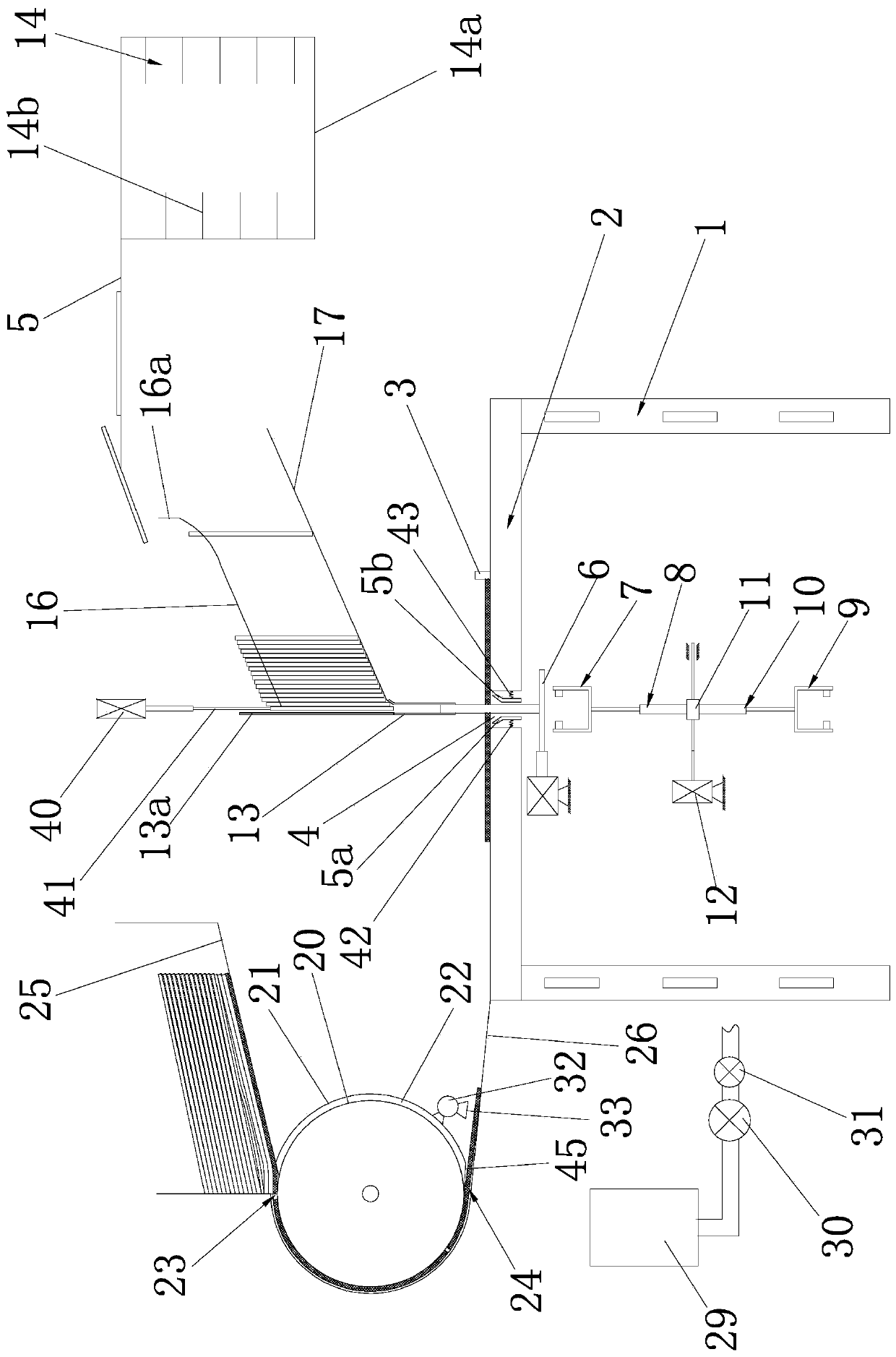

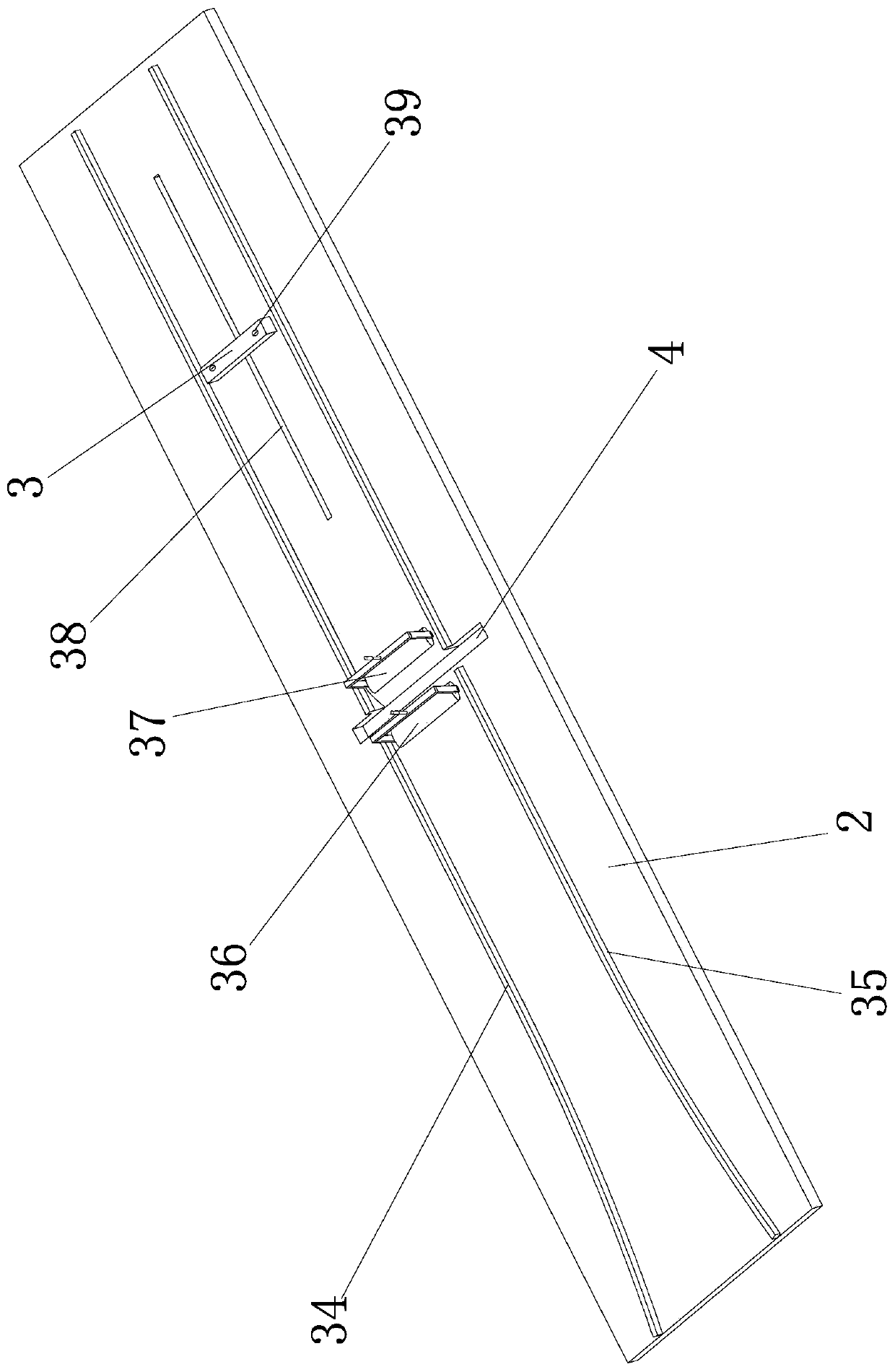

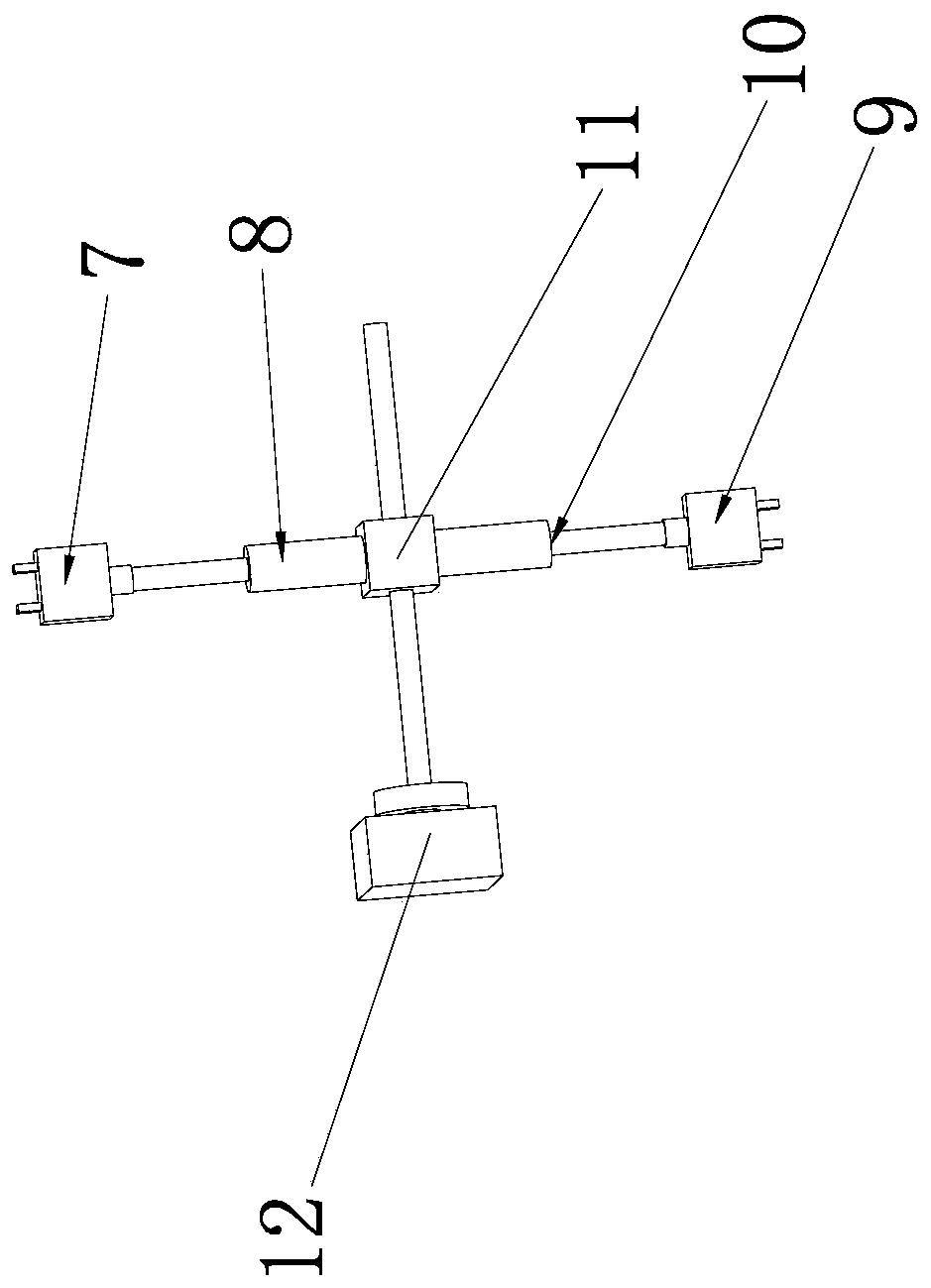

[0036] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a cortical tab packaging machine includes a frame 1, a linear vibrating feeder for conveying cortical tabs is arranged on the frame 1, and the linear vibrating feeder includes a vibrating feeding plate 2 placed horizontally on the frame 1, The top surface of the vibrating feeding plate 2 is provided with a limit bar 3, and the middle part of the vibrating feeding plate 2 is provided with a pull ring seat hole 4 passing through its top and bottom. A vertical clamping channel is formed between them, a baffle plate 6 is horizontally arranged below the clamping plate, and the baffle plate 6 is connected with a driving mechanism capable of moving back and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com