Quantitative dough kneading fermentation machine for food fermentation

A food fermentation and basin technology, applied in dough fermenters, mixing/kneading with vertical installation tools, application, etc., can solve the problems of too much or too little flour, sticky dough, and blockage in the feeding port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

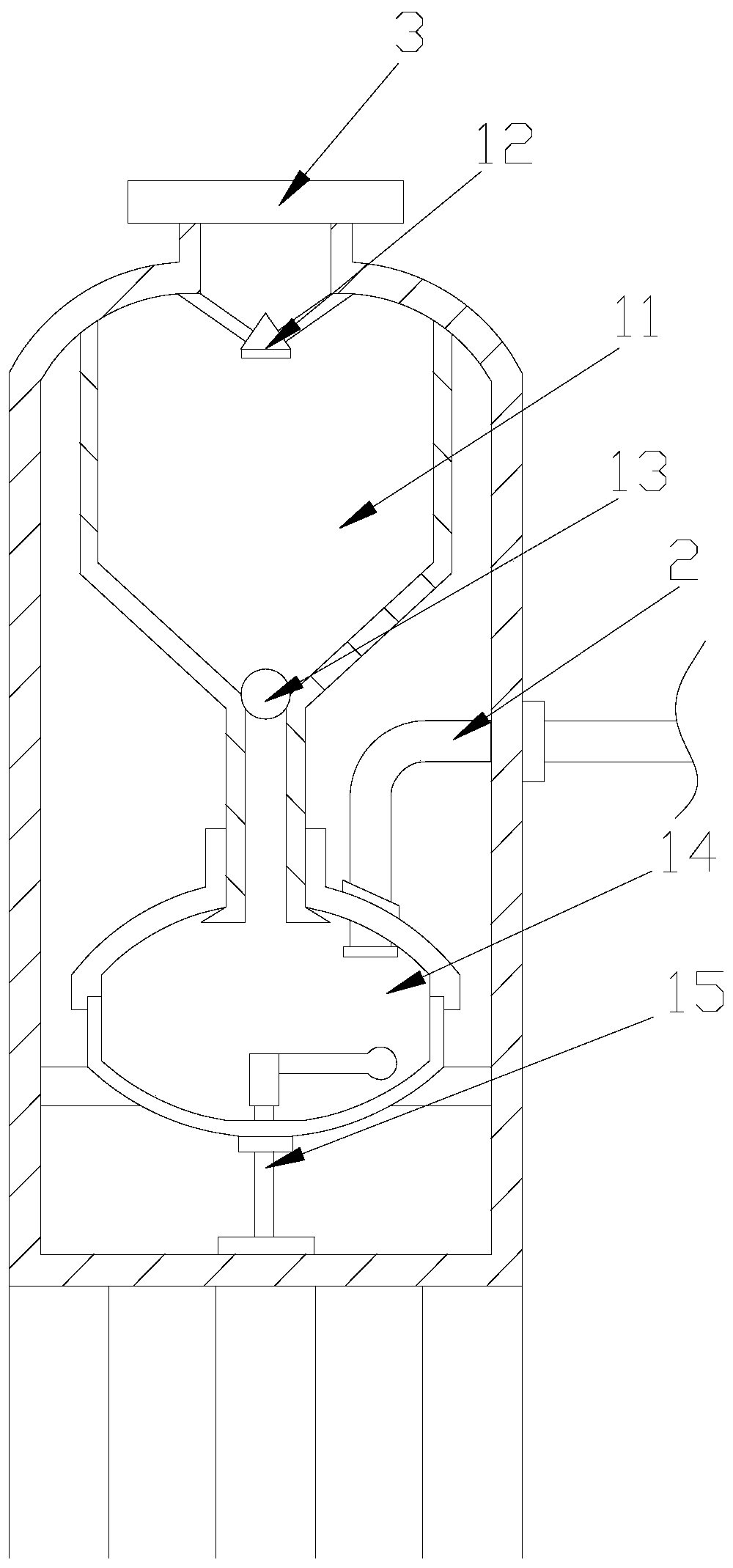

[0026] Example 1: Please refer to Figure 1-Figure 6 , The specific embodiment of the present invention is as follows: its structure includes a main body 1, a water inlet pipe 2, a top cover 3, and a material taking port 4. The side end of the main body 1 is provided with a water inlet pipe 2, and the top cover 3 is clamped to the main body 1. At the top end of the main body 1, the reclaiming port 4 is provided at the front end of the main body 1, and the main body 1 includes a storage box 11, a feeding device 12, a feeding device 13, and a basin 14, and a noodle rod 15. The storage box 11 is embedded in the inner top of the main body 1, the feeding device 12 is installed at the top of the storage box 11, the unloading device 13 is installed at the bottom end of the storage box 11, and the basin 14 is welded to the main body 1. At the inner bottom end of the bowl, the mixing rod 15 penetrates the bowl 14.

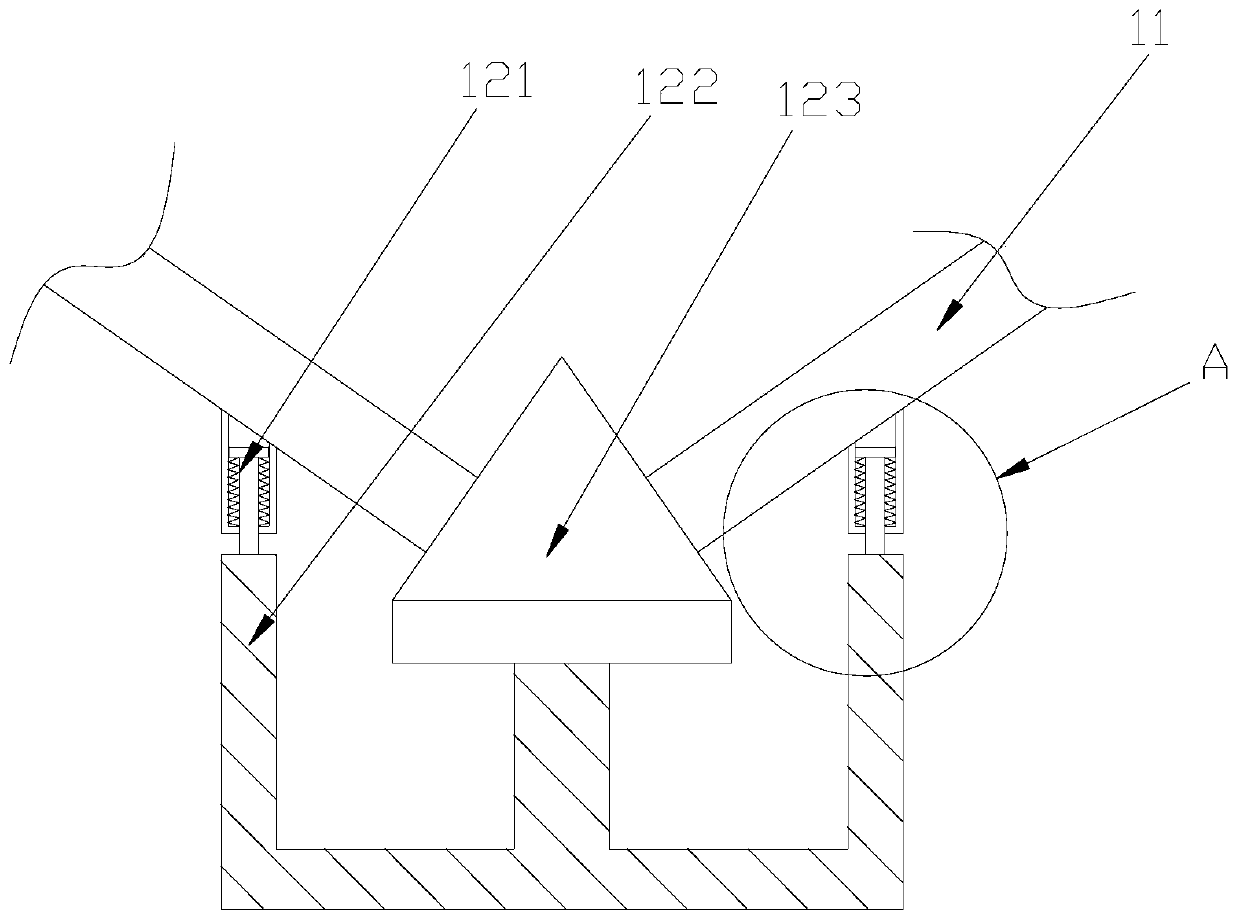

[0027] The feeding device 12 includes an elastic switch 121, a connecting...

Embodiment 2

[0032] Example 2: Please refer to Figure 7-Figure 8 , The specific embodiment of the present invention is as follows: the blanking device 13 includes a groove 131, a limiting block 132, a third spring 133, and a blanking roller 134, the grooves 131 are provided with two, and the grooves 131 are respectively Set on both sides of the bottom of the blanking device 13, the limiting block 132 is installed at the upper end of the groove 131, the third spring 133 is installed below the limiting block 132, and the blanking roller 134 is installed on the blanking device At the center of the bottom of 13, the discharging roller 134 is cylindrical, which facilitates close contact between the discharging roller 134 and the limiting block 132, and prevents the flour from slipping off the sides.

[0033] The blanking roller 134 includes a roller body c1, a rotating shaft c2, and a clamping groove c3. Two rotating shafts c2 are provided on both sides of the roller body c1. The clamping groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com