Gas density relay with online self-checking function and checking method thereof

A technology of gas density and relay, applied in the field of electric power, can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

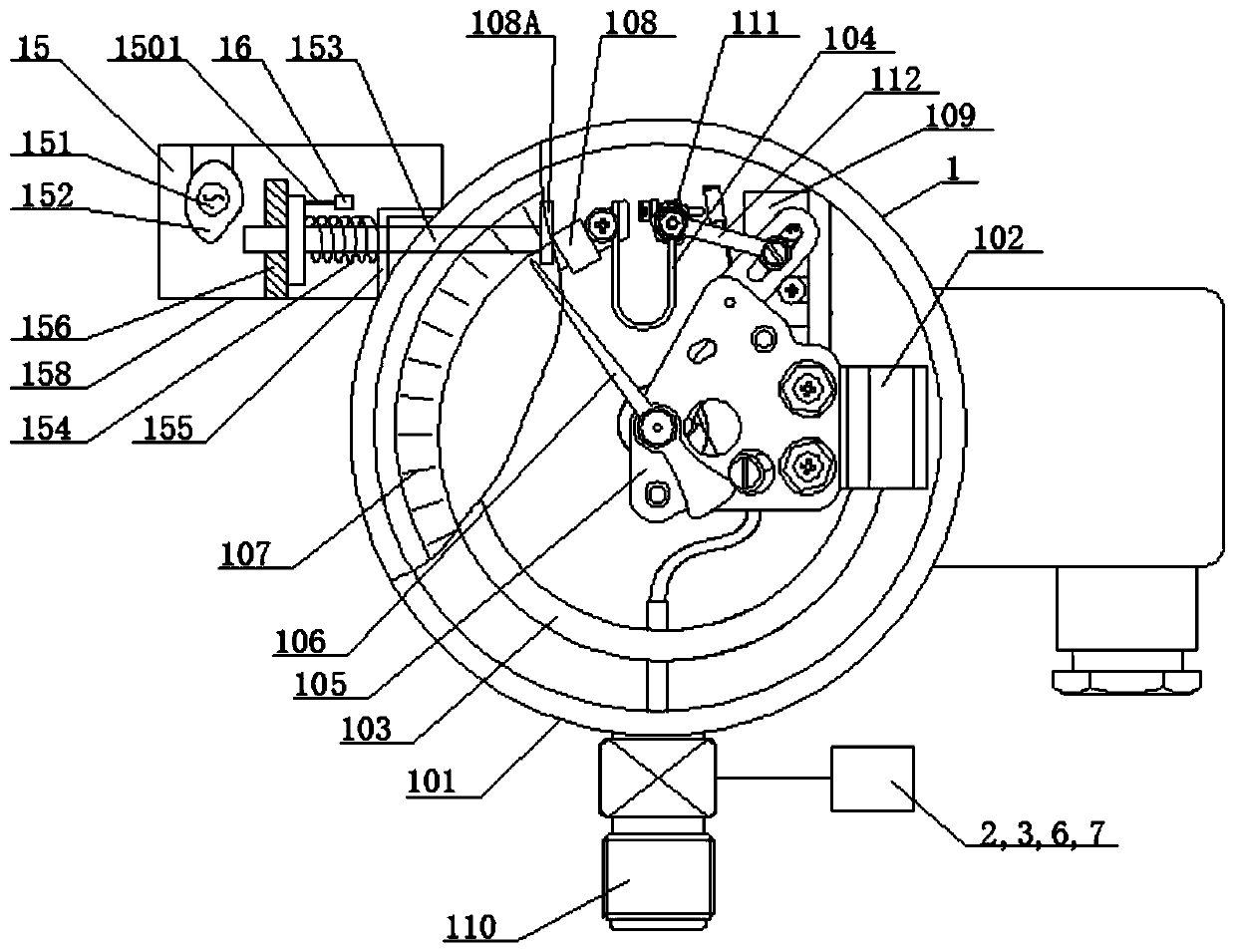

[0094] figure 1 This is a schematic diagram of the structure of a gas density relay according to the first embodiment of this application. Such as figure 1 As shown, a gas density relay includes: a gas density relay body 1, a first pressure sensor 2, a temperature sensor 3, a force sensor 16, a contact action mechanism 15, an online verification contact signal sampling unit 6 and an intelligent control unit 7 .

[0095] Among them, the gas density relay body 1 includes a housing 101, a base 102, an end seat 108, a pressure detection element 103, a temperature compensation element 104, a number of signal generators 109, a movement 105, Pointer 106, connecting rod 112, dial 107. The movement 105 is fixed on the base 102; one end of the pressure detecting element 103 (Baden tube) is fixed on and connected to the base 102, and the pressure detecting element 103 (Baden tube) ) Is filled with sealing gas, the other end of the pressure detection element 103 (Baden tube) is connected t...

Embodiment 2

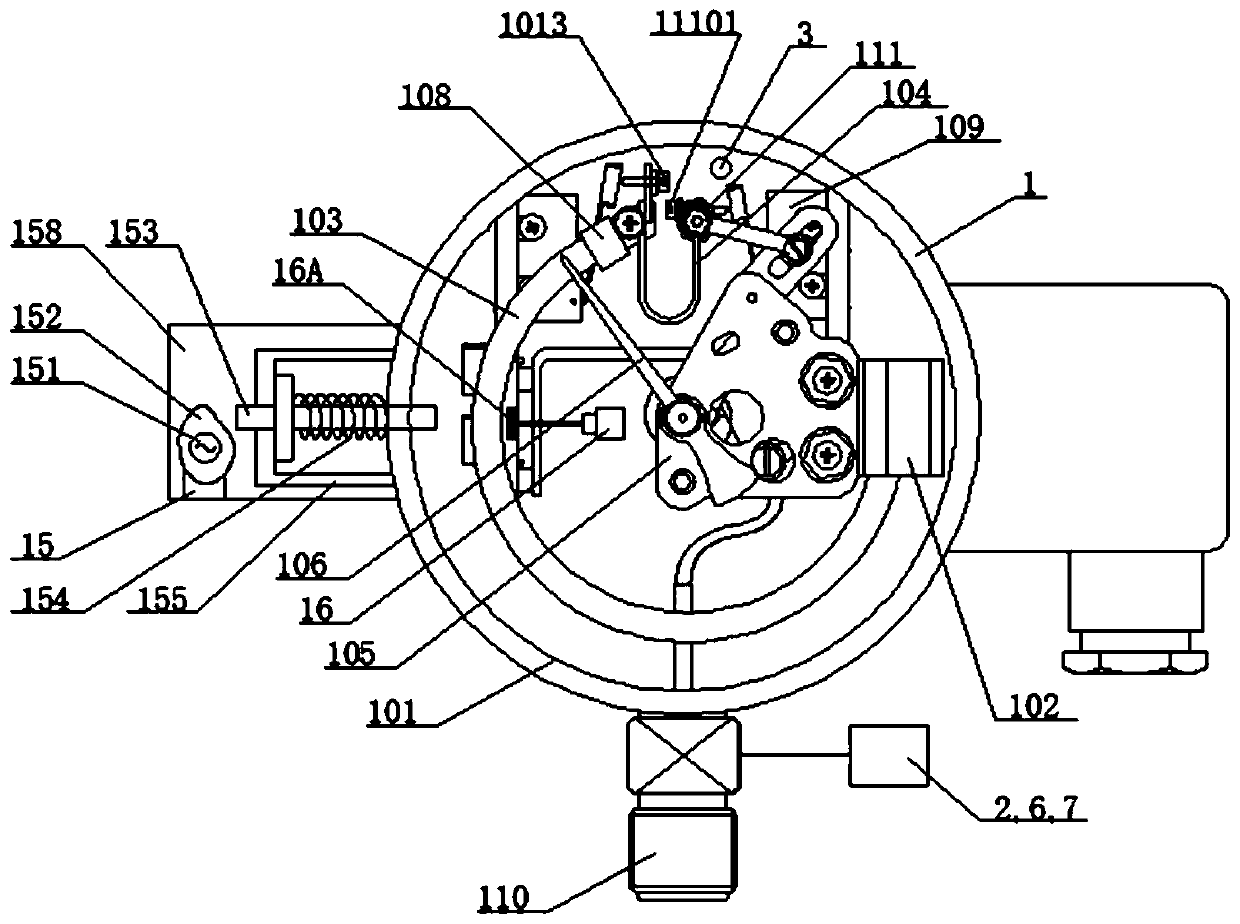

[0122] Such as figure 2 As shown, the second embodiment of the present invention provides a gas density relay or gas density monitoring device with online self-checking function.

[0123] The difference from the first embodiment is:

[0124] 1) The driving contact action mechanism 15 is arranged on the outside of the housing 101, and is arranged corresponding to the pressure detection element 103 (Baden tube) of the gas density relay body 1; the driving contact action mechanism 15 is configured as an indirect Therefore, the signal action mechanism 111 of the gas density relay body 1 is displaced correspondingly, and the contact signal action of the gas density relay body 1 is generated.

[0125] The driving contact action mechanism 15 includes an outer cover 158 with an open end, and a driving part 151, a force transmission member 152 (cam), a push rod 153, a spring 154, and a fixing frame 155 arranged in the outer cover 158; the opening of the outer cover 158 Towards the housing 1...

Embodiment 3

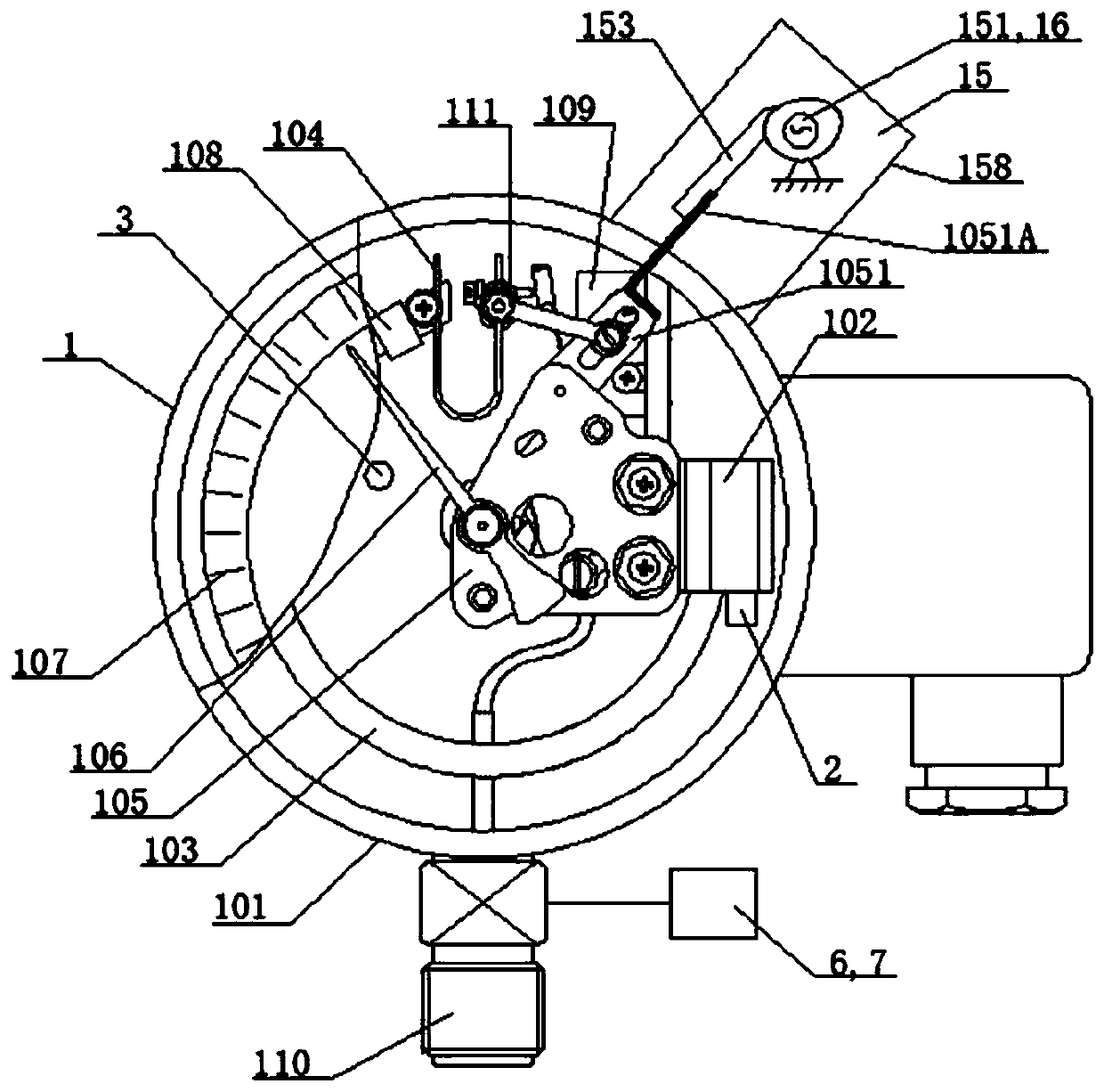

[0131] Such as image 3 As shown, the third embodiment of the present invention provides a gas density relay or gas density monitoring device with an online self-checking function.

[0132] The difference from the first embodiment is:

[0133] 1) The driving contact action mechanism 15 is arranged on the outside of the housing 101, and includes an outer cover 158 with an open end, and a driving part 151, a force transmission member 152 (cam) and a push rod 153 arranged in the outer cover 158; the outer cover 158 is sealed (Mainly waterproof intrusion) It is connected to the housing 101 of the gas density relay body 1, and the opening of the outer cover 158 faces the housing 101. The driving contact action mechanism 15 is configured to indirectly cause the signal action mechanism 111 of the gas density relay body 1 to correspondingly shift, thereby causing the gas density relay body 1 to generate contact signal actions.

[0134] The movement 105 of the gas density relay body 1 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com