Automatic detection device for electrical automation equipment

An automatic detection device, electrical automation technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as displacement, complex operation, and inability to perform automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

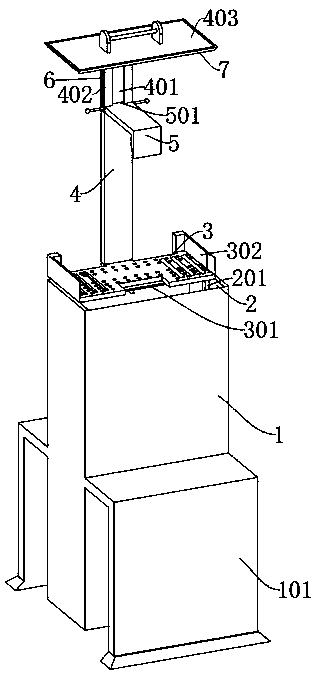

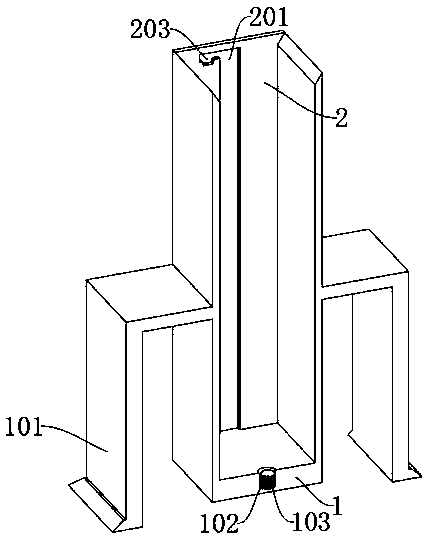

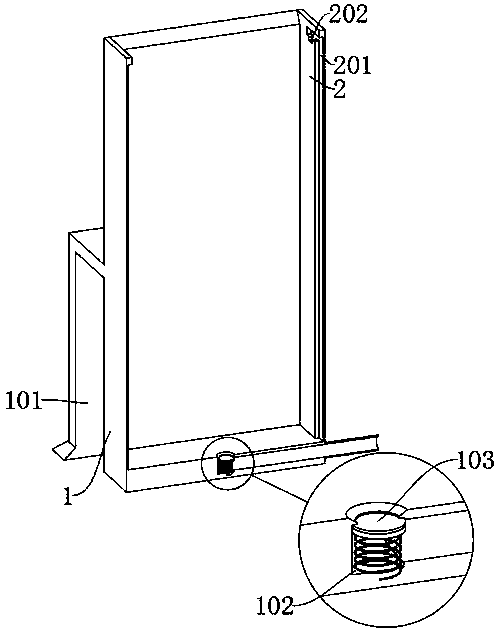

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The invention provides an automatic detection device for electrical automation equipment, comprising: a main body 1, an inner compartment 2, a bottom part 3, a support part 4, a fixing part 5, a pressure plate 6 and a sealing part 7; the main body 1 is a rectangular structure, and the main body 1 There is a drain pipe on the bottom side of the bottom, and the bottom hole 102 is used for drainage, so that the sealing plate 103 can be sealed inside, so that when the control cabinet is poorly sealed, water can enter the inside of the control cabinet, so that The insertion rod at the bottom of the bottom part 3 can push the sealing plate 103, so that the water can be discharged, and the deformation of the control cabinet caused by water and pressure is avoided; the inner compartment 2 includes a side groove 201 and a fixing groove 202; the inner compartment 2 is a rectangular structure, and the inner compartment 2 B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com