Adaptive clamping and positioning device and method for FDZ damper

A technology of clamping and positioning, anti-vibration hammer, applied in the direction of mechanical vibration damping device, etc., can solve the problems of non-adjustment, poor matching degree of anti-vibration hammer, and inconvenient management and handling of the clamping head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

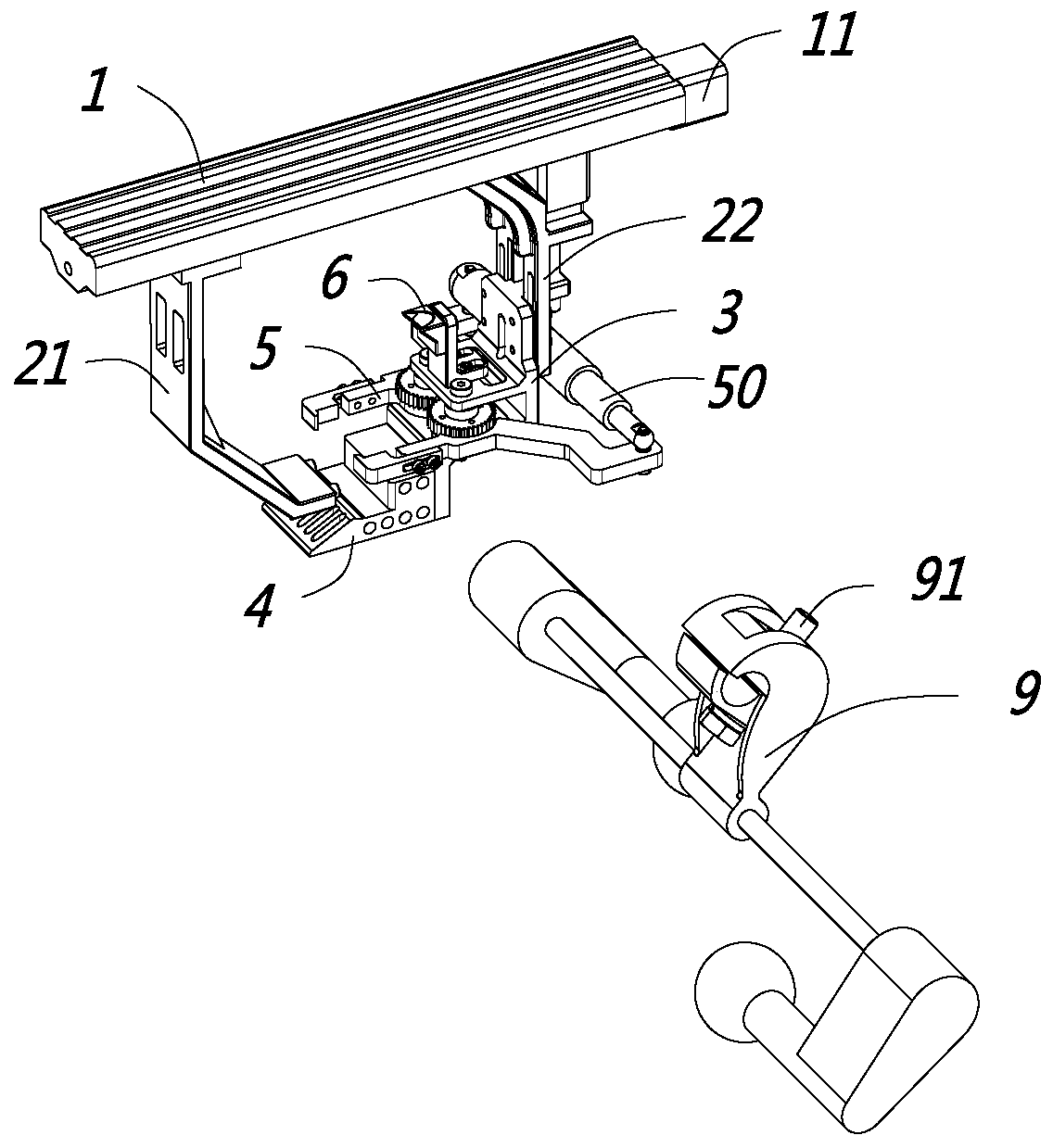

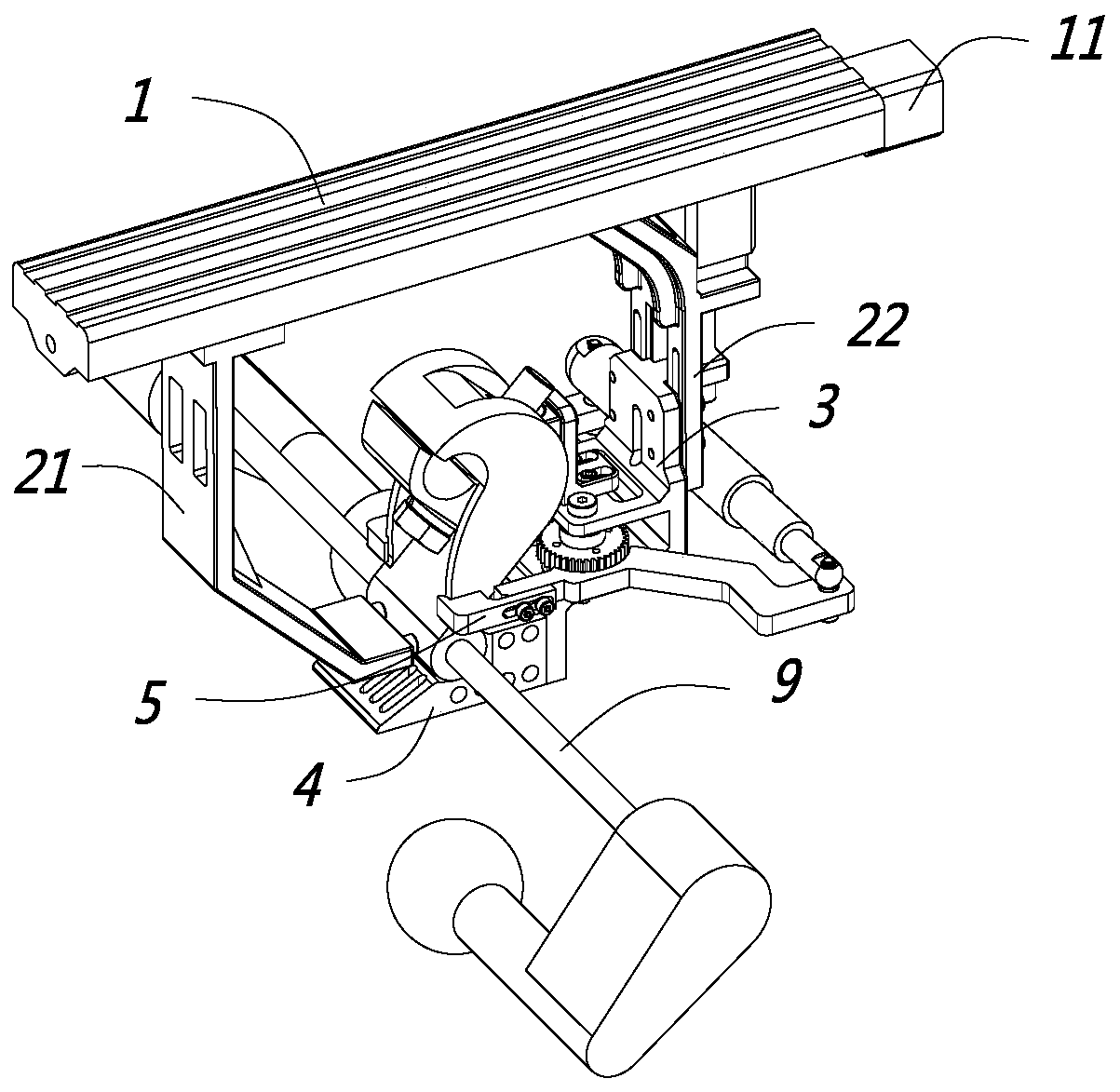

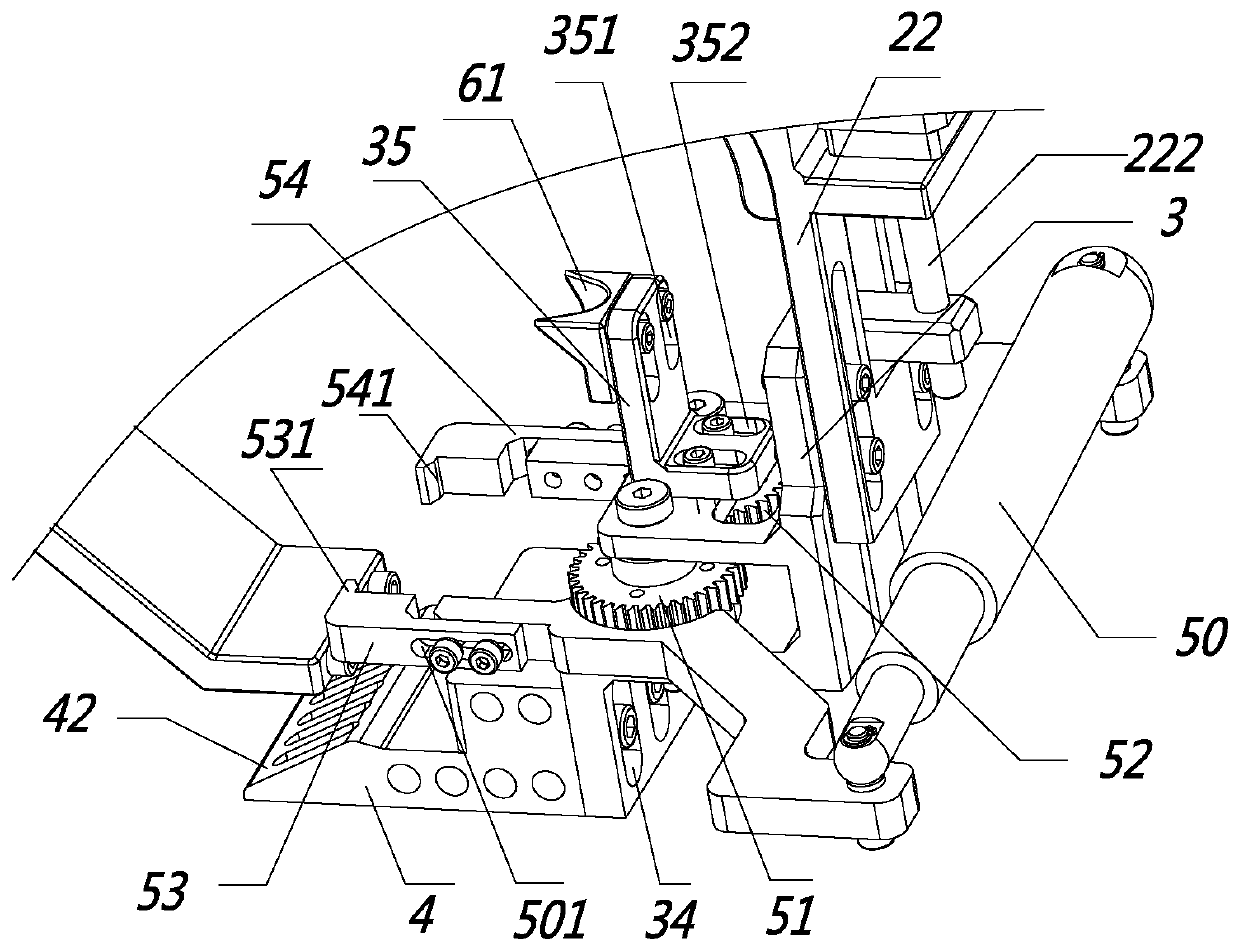

[0040] Such as Figure 1 to Figure 4 As shown, this embodiment is an adaptive clamping and positioning device for an FDZ anti-vibration hammer. The anti-vibration hammer 9 is fastened by bolts 91, and includes a main slide 1, and a limit arm 21 and The clamping arm 22 that is slidably arranged relative to the limit arm 21, the clamping arm 22 is driven by the first driver to slide on the main slide 1, the clamping arm 22 is provided with a clamping mechanism, and the clamping arm 22 is provided with a clamping mechanism. The mechanism slides vertically on the clamping arm 22 through the second driver, and the clamping mechanism includes an anti-vibration hammer bracket 4 and a gripper 5 located above the anti-vibration hammer bracket 4 , and the anti-vibration hammer bracket 4 Used to limit the bottom of the anti-vibration hammer 9, the clamp 5 clamps the anti-vibration hammer 9 horizontally, the clamp 5 is connected with a third driver 50, and the clamping mechanism also incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com