Standardized load-bearing support and hanger system and installation method thereof

A support and hanger system technology, applied in the direction of pipeline supports, electrical components, pipes/pipe joints/fittings, etc., can solve the problems of low standardization, inconvenient installation, poor versatility, etc., to achieve clear force, convenient installation and disassembly, Easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

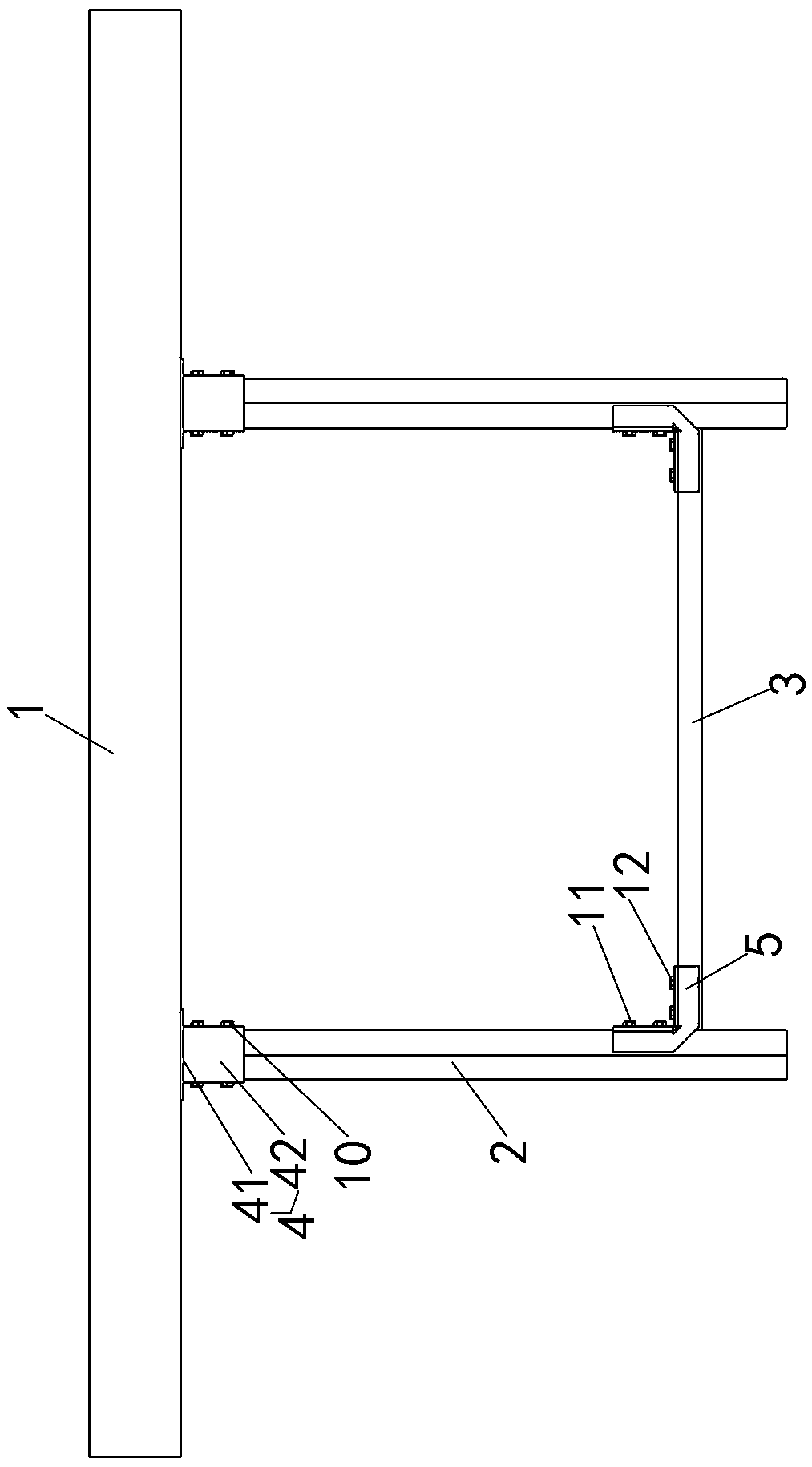

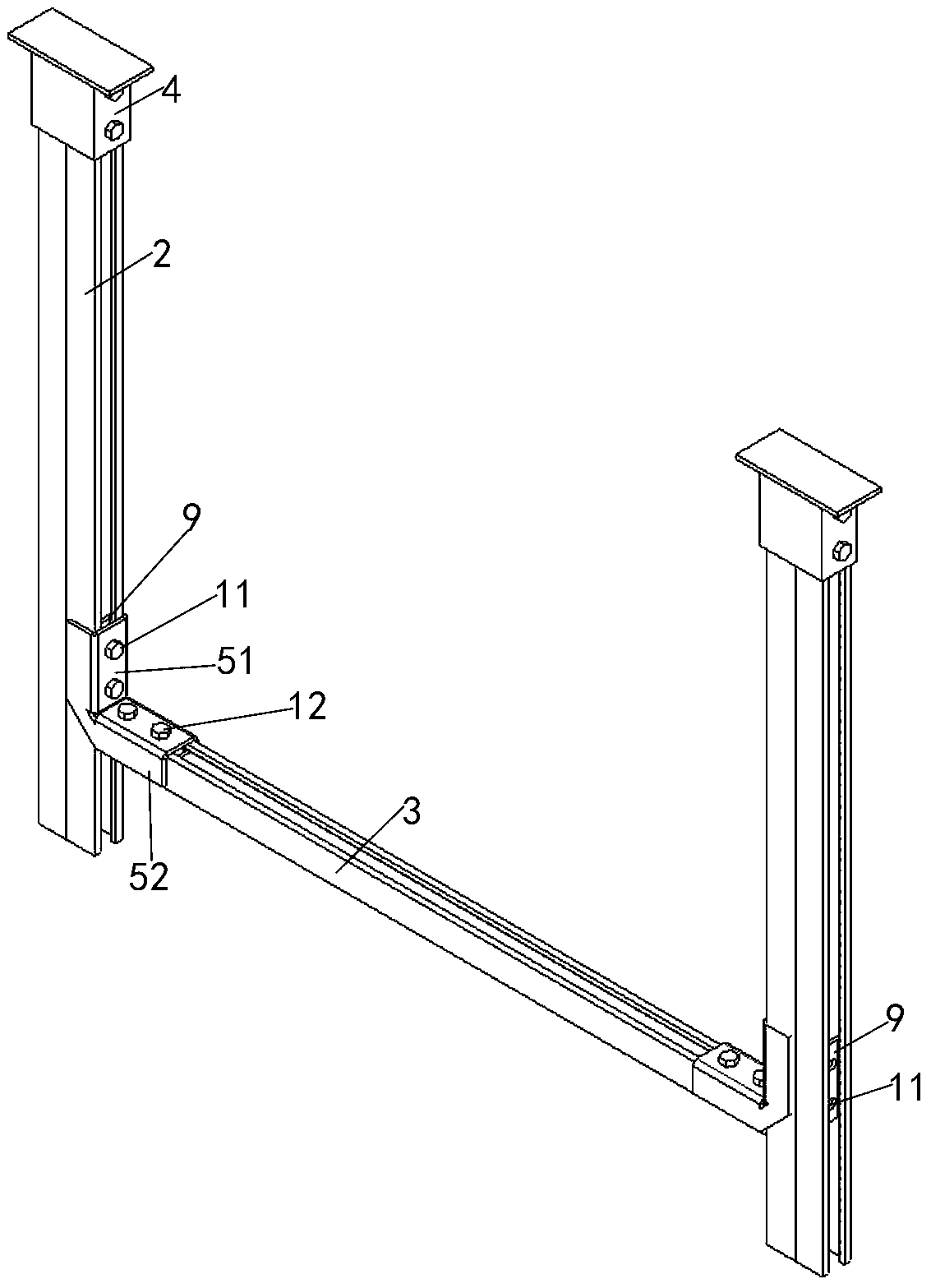

[0045] Embodiment one sees Figure 1-10 As shown, a standardized load-bearing support and hanger system includes a top beam 1 and a hanger fixed on the lower side of the top beam 1. The hanger includes two vertical arms 2 and two ends are fixedly connected between the two vertical arms 2. Between the crossarm 3.

[0046] The top of the vertical arm 2 is fixedly connected to the lower side of the hanger through the base 4 . Both ends of the cross arm 3 are fixedly connected to the vertical arm 2 through corner connection components.

[0047] The vertical arm 2 or the cross arm 3 is a section of channel steel standard part 7 or is formed by connecting two sections of channel steel standard parts 7 through the extension connection assembly. The opening of the vertical arm 2 faces the cross arm 3, and the The opening of the load 3 faces upwards.

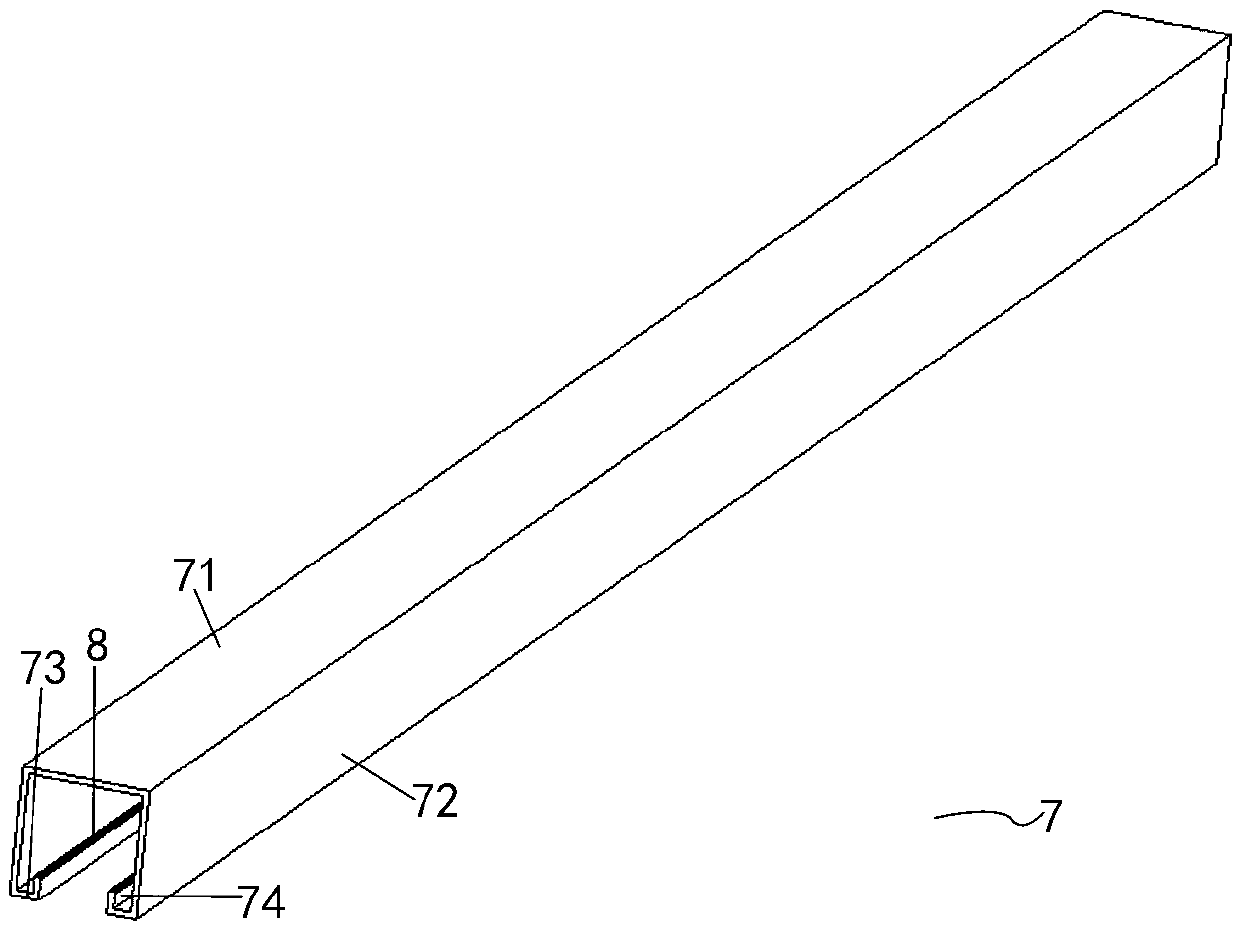

[0048] The channel steel standard part 7 includes a channel bottom plate 71, channel side plates 72 on both sides and channel side f...

Embodiment 2

[0058] Embodiment two see Figure 11 As shown, the difference from the first embodiment is that the cross arm 3 is also double channel steel. see Figure 12 As shown, at this time, the corner connecting components are arranged symmetrically along the upper and lower sides of the cross arm 3, and if there are extended connecting components, they are symmetrically arranged in pairs along the upper and lower sides of the cross arm 3.

[0059] The installation method of this standardized load-bearing support and hanger system, the installation steps are as follows:

[0060] Step 1: Design the form of the vertical arm 2, the form of the corresponding base 4, the form of the cross arm 3, the number of corresponding corner connection components and whether the connection components need to be extended according to the force requirements, and when the connection components need to be extended number; and process the first connecting bolt 10, the second connecting bolt 11, the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com