Automatic bottle opening method for medical injection ampoule bottles

A technology for ampoules and medical use, applied in the field of medical devices, can solve the problems that the bottle opening equipment does not have disinfection and waste bottle recycling, cannot realize automatic opening, and has low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

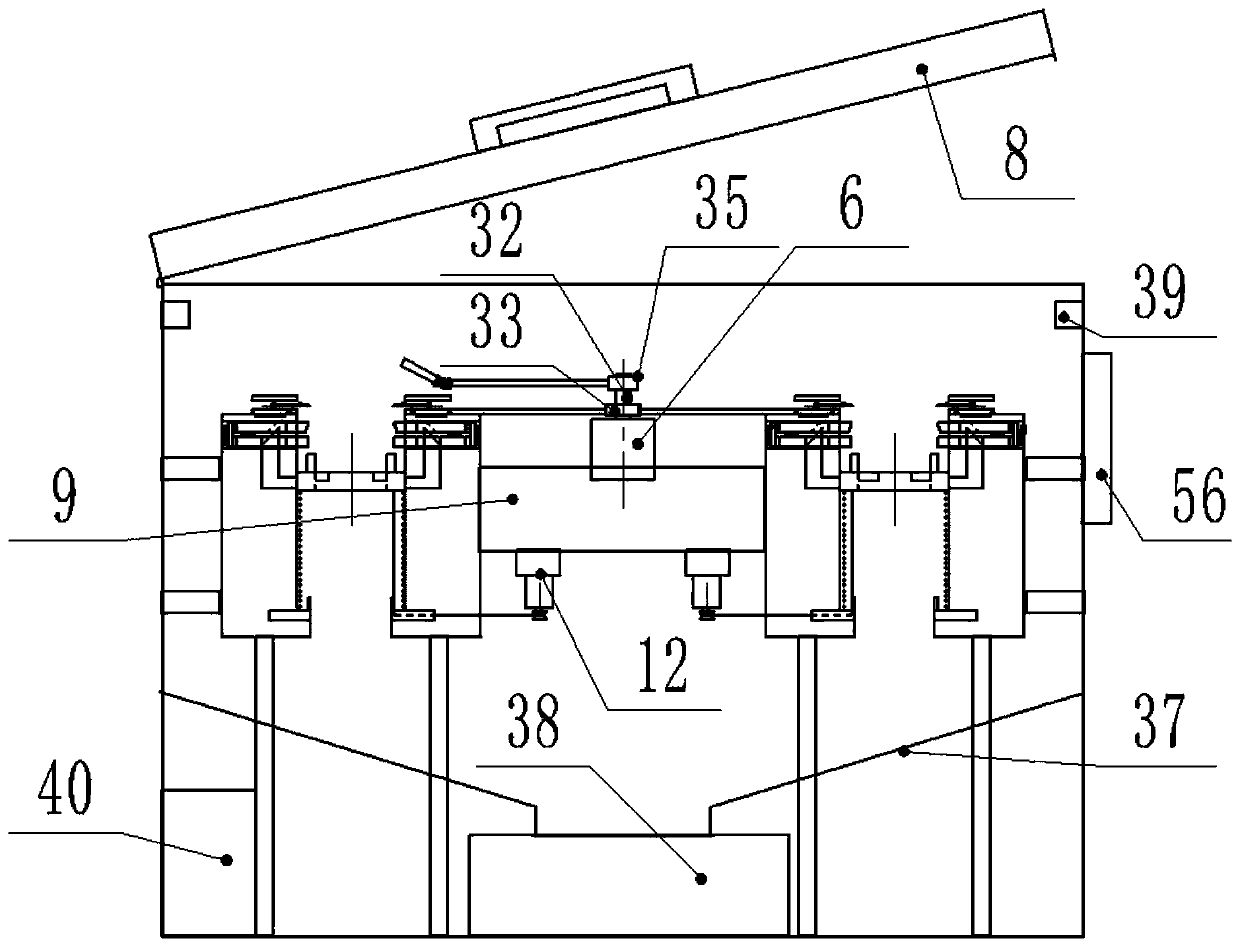

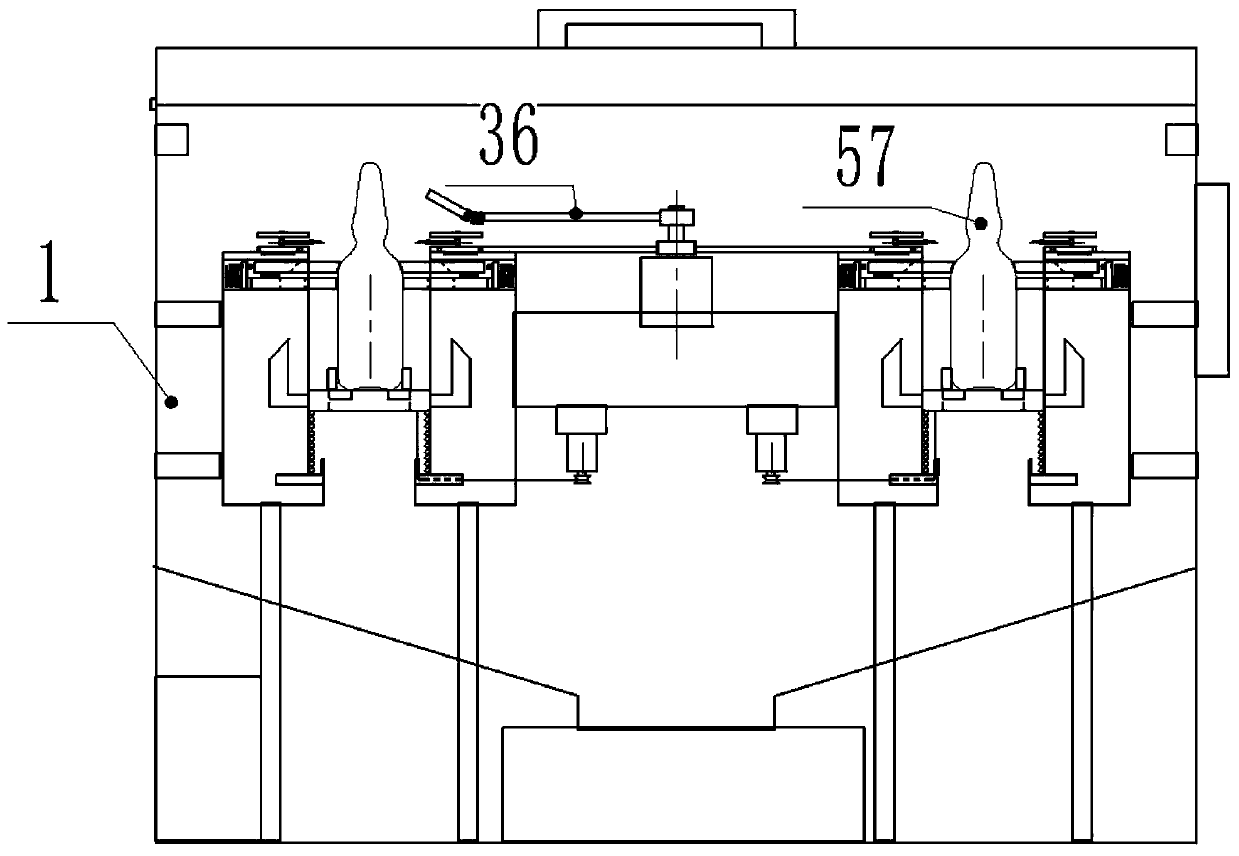

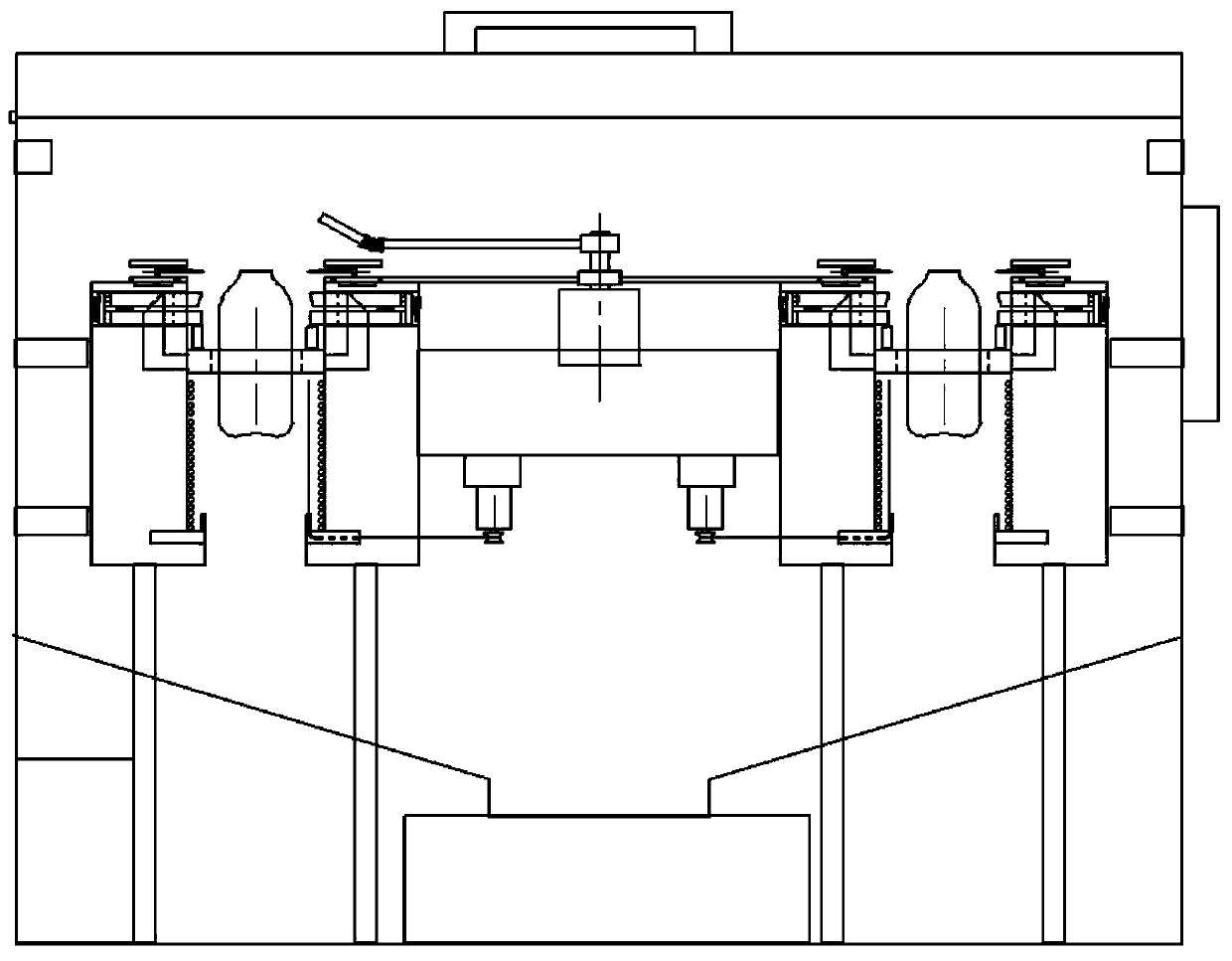

[0047] Such as Figure 1-10 As shown, the automatic bottle opening method for medical injection ampoules of the present invention comprises steps:

[0048] Step 1, a bottle opener box 1 with a box cover 8 is set, a bottle opener installation platform 9 is set up in the bottle opener box 1, and a plurality of ampoule bottle placement cylinders 2 are arranged around the bottle opener installation platform 9, each An ampoule bottle placement tube 2 is provided with a movable plug seat 3, and the ampoule bottle placement tube 2 below the movable plug seat 3 is provided with a back-moving spring 10, and the bottom of each movable plug seat 3 is connected to the opening via a stay cord 11. Corresponding coil pull motor 12 transmission connection below the middle part of device mounting table 9;

[0049] Step 2, an ampoule bottle positioner 4 is provided on the upper part of the ampoule bottle placement cylinder 2, the ampoule bottle positioner 4 includes at least three positioning ...

Embodiment 2

[0075] Such as Figure 1-10 As shown, the automatic bottle opening method for medical injection ampoules of the present invention, on the basis of the above-mentioned embodiments, the bottle opener installation table 9 and the bottle opener box 1 sidewall and bottom all leave space, and the bottle opener is installed The platform 9 below is provided with a waste bottle funnel 37, and the bottle opener 1 below the waste bottle funnel 37 is provided with a pull-out bottle collection drawer 38. The bottle opener installation table 9 and the bottle opener box 1 side walls and bottom all leave space, and a waste bottle funnel 37 is provided below the bottle opener installation table 9, and a puller is provided in the bottle opener box 1 below the bottle opener funnel 37. Formula collection bottle drawer 38. The knocked-off nipple part falls into the gap between the bottle opener installation platform 9 and the side wall of the bottle opener 1 under the centrifugal force and the st...

Embodiment 3

[0078] Such as Figure 1-10 As shown, the automatic bottle opening method for medical injection ampoules of the present invention, on the basis of the above-mentioned embodiments, the movable plug seat 3 includes an annular plug seat 41 and a clamping block 42, and the annular plug seat 41 is surrounded by a Three slide grooves 43, the clamping block 42 includes an arc clamping block 44 and a sliding bar 45, the arc clamping block 44 is connected and arranged on the sliding bar 45, and the clamping block 42 is inserted on the sliding bar 45 through the sliding bar 45. In the groove 43, a tension spring 46 is connected between the rear side of the arc-shaped clamp block 44 and the outer ring surface of the annular plug seat 41, and a rubber layer 47 is laid on the inner ring surface of the arc-shaped clamp block 44, and the rubber layer 47 can play a buffering role , to avoid the arc clip 44 from clipping the bottle.

[0079] An annular stay cord tunnel 48 is provided at the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com