Dry-wet separation device for separating kitchen garbage

A technology for dry-wet separation and kitchen waste, applied to centrifuges and other directions, can solve problems such as prolonging fermentation time, achieve high separation efficiency and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

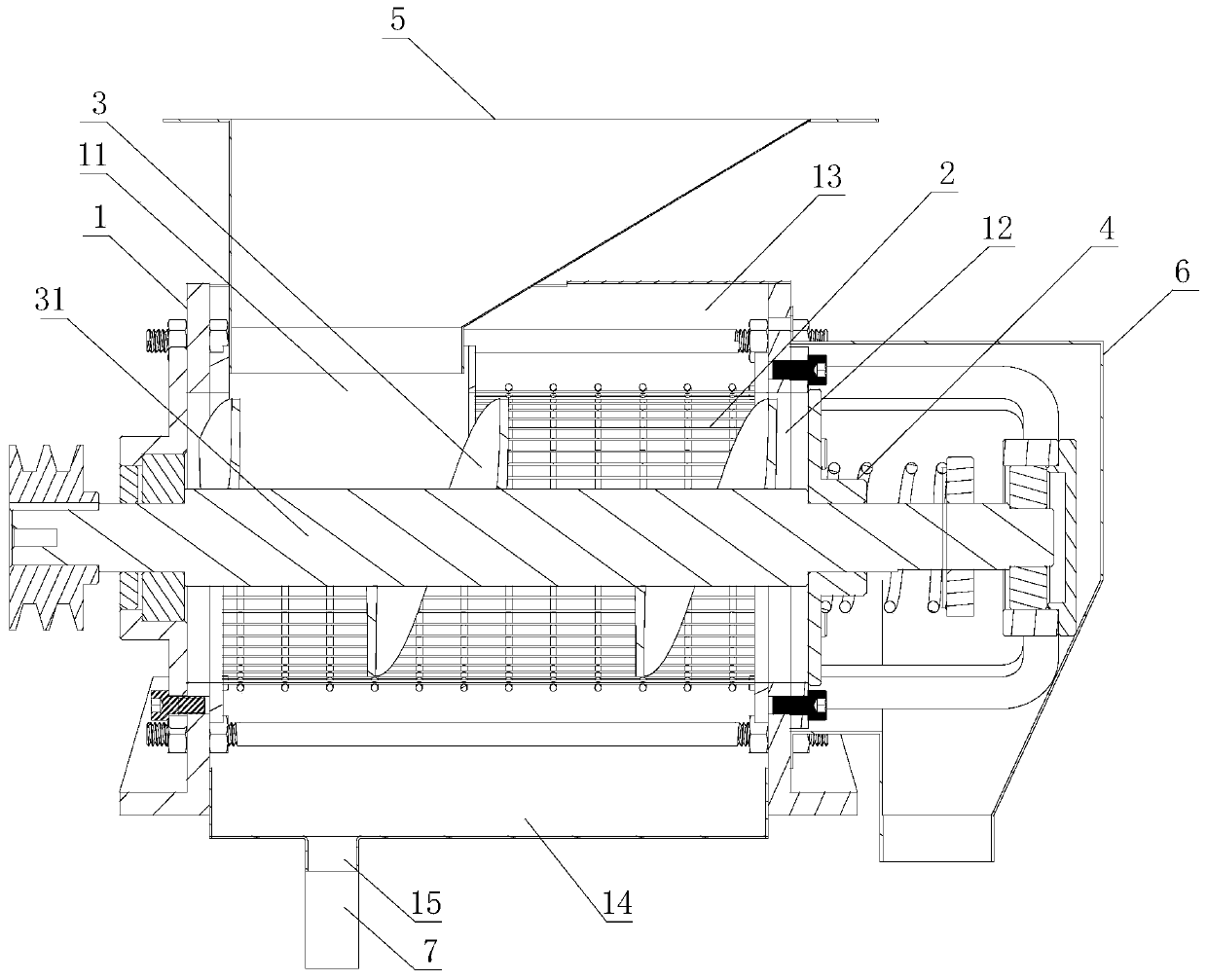

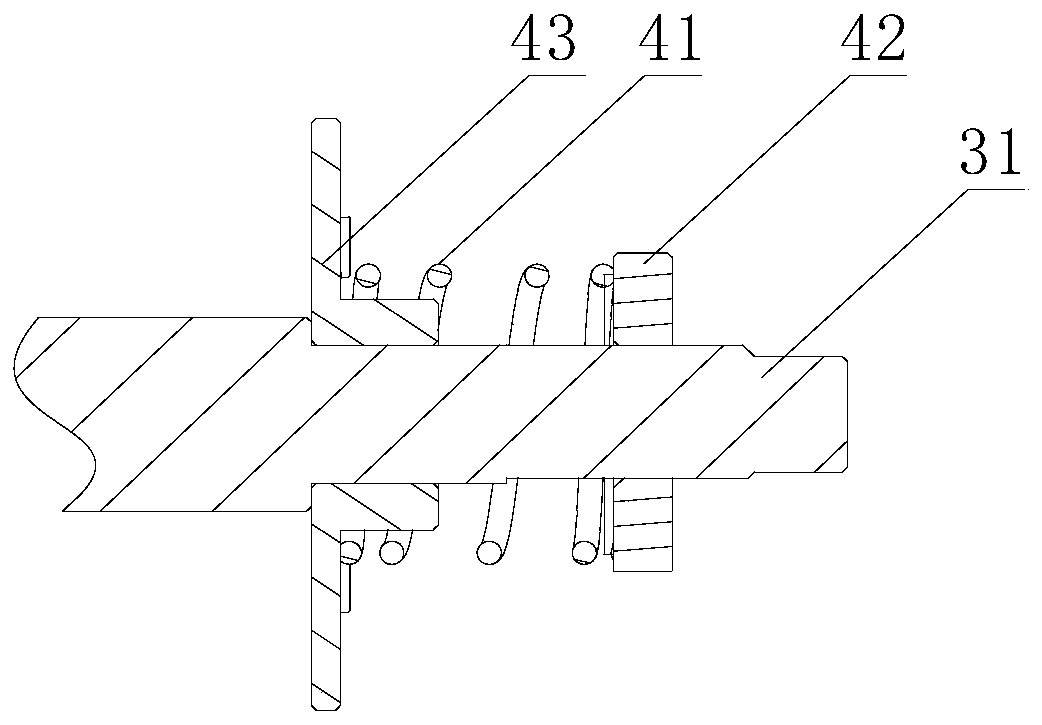

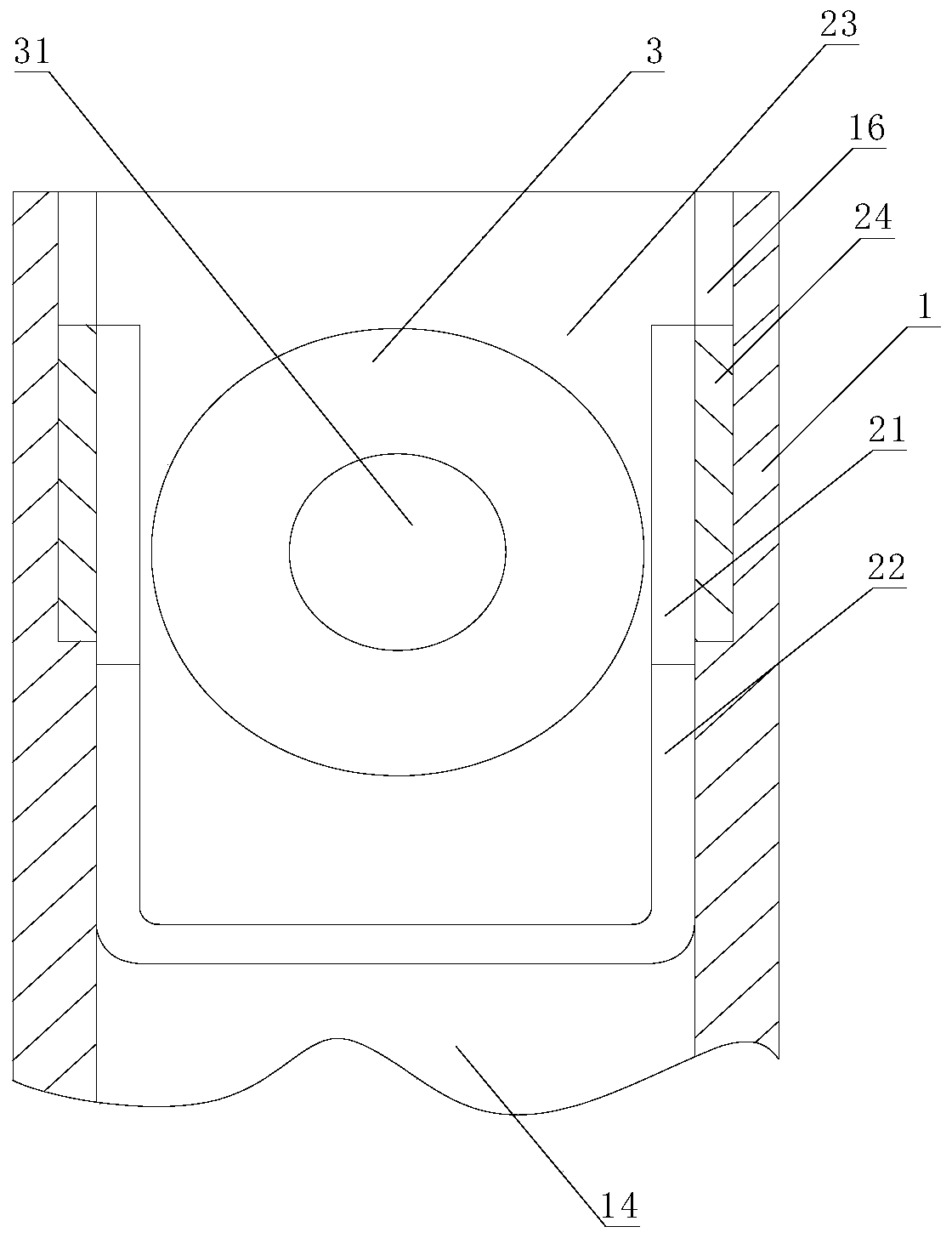

[0020] Such as figure 1 , figure 2 , image 3 As shown, a dry-wet separation device for kitchen waste separation includes a box body 1, a filter assembly 2 and a spiral blade 3, the box body 1 includes a feed end 11 and a discharge end 12, and the filter assembly 2 is fixedly connected in the box body 1, and divides the box body 1 into an upper cavity 13 and a lower cavity 14, and the spiral blade 3 is rotatably connected in the upper cavity 13 through a rotating shaft 31, and is located above the filter assembly 2 , the feed end 11 is arranged on the top of the upper cavity 13, the rotating shaft 31 also includes a pre-tensioning device 4 for adjusting the dry humidity of the material, and the pre-tensioning device 4 is arranged on the rotating shaft 31 outside the box body 1 for use In order to adjust the discharge size of the material, the lower cavity 14 is provided with a water outlet 15 .

[0021] The material is conveyed into the box body 1 through the feed end 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com