Real-time control method for natural environment concrete exposed surface moisturizing maintenance process

A technology of real-time control and natural environment, which is applied in the field of real-time control of the moisturizing and curing process of the exposed surface of concrete in natural environment, can solve the problems such as the inability to guarantee the quality of concrete, the lack of a suitable method for real-time control, and the difficulty in ensuring the goal of moisturizing and curing of concrete, etc. The effect of good effect, accurate result and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

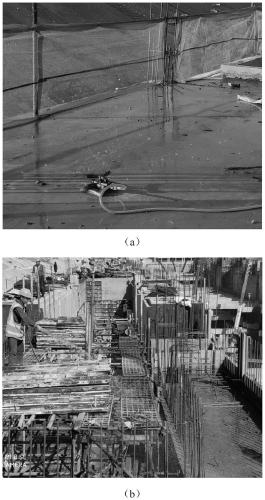

[0046] Real-time control of concrete spraying and moisturizing maintenance on the upper lock head of Qingyuan second-line ship lock in Guangdong Province

[0047] 1. Real-time control method for moisturizing and curing process of concrete exposed surface in natural environment

[0048] Such as image 3 As shown, the real-time control method for the moisturizing and curing process of the exposed surface of natural environment concrete provided by this embodiment 1 includes the following steps:

[0049] Step 1. Real-time collection, ambient air humidity, and ambient wind speed data

[0050] At the concrete maintenance site on the top of the upper lock head of the Qingyuan No. 2 ship lock, construction maintenance workers use a thermo-hygrometer to measure the ambient temperature and ambient air humidity on the concrete curing surface every 1 to 2 hours, and the ambient wind speed adopts the weather forecast value. At 16:50 pm on November 29, 2018, the actual temperature at th...

Embodiment 2

[0067] Real-time control of concrete spraying, moisturizing and curing of the top-sealing layer of the downstream section of the right bank of the lower lock head of the Qingyuan second-line ship lock in Guangdong Province

[0068] On the afternoon of December 3, 2018, the joint research team of Wuhan University and the Qingyuan Ship Lock Project Department of Yuantian Group inspected the site, studied in detail the pouring of the ship lock concrete at that time, and determined the real-time control of moisturizing and maintenance on the topping layer of the downstream section on the right bank of the lower lock head Applied research, as an example of pouring concrete in low temperature seasons.

[0069] The concrete pouring time for the capping layer of the downstream section on the right bank of the lower gate head is from 5:00 on December 4, 2018 to 9:00 on December 4, 2018. At 7:00 am on December 4, 2018, the real-time control application research work began at the site. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com