Lifting anti-shaking device based on hoisting equipment

A lifting equipment and anti-shake technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of inability to move the transmission wheel up and down, inability to place goods stably, low efficiency of lifting equipment, etc., to improve mobility Performance, good stability, good effect of mitigating jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

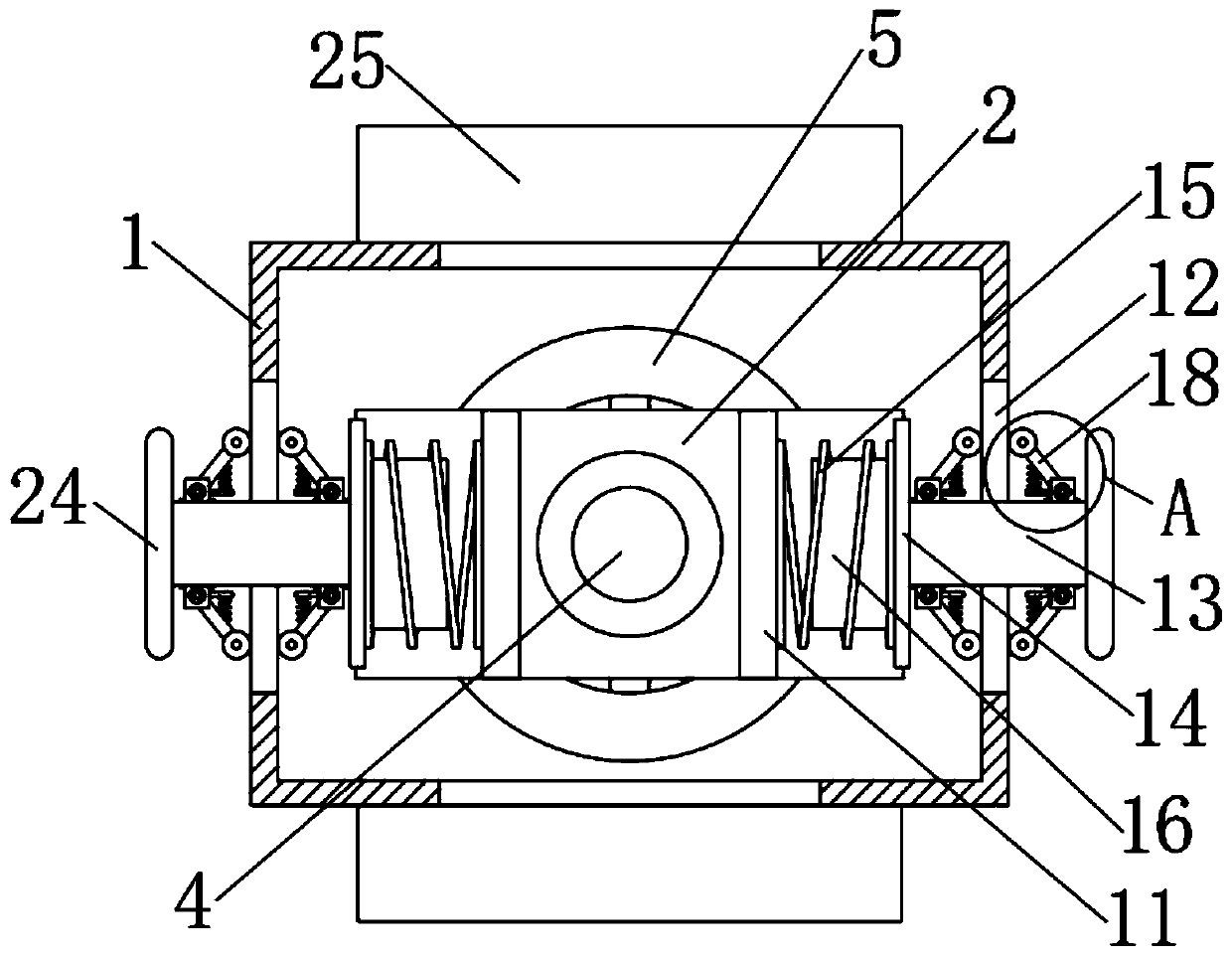

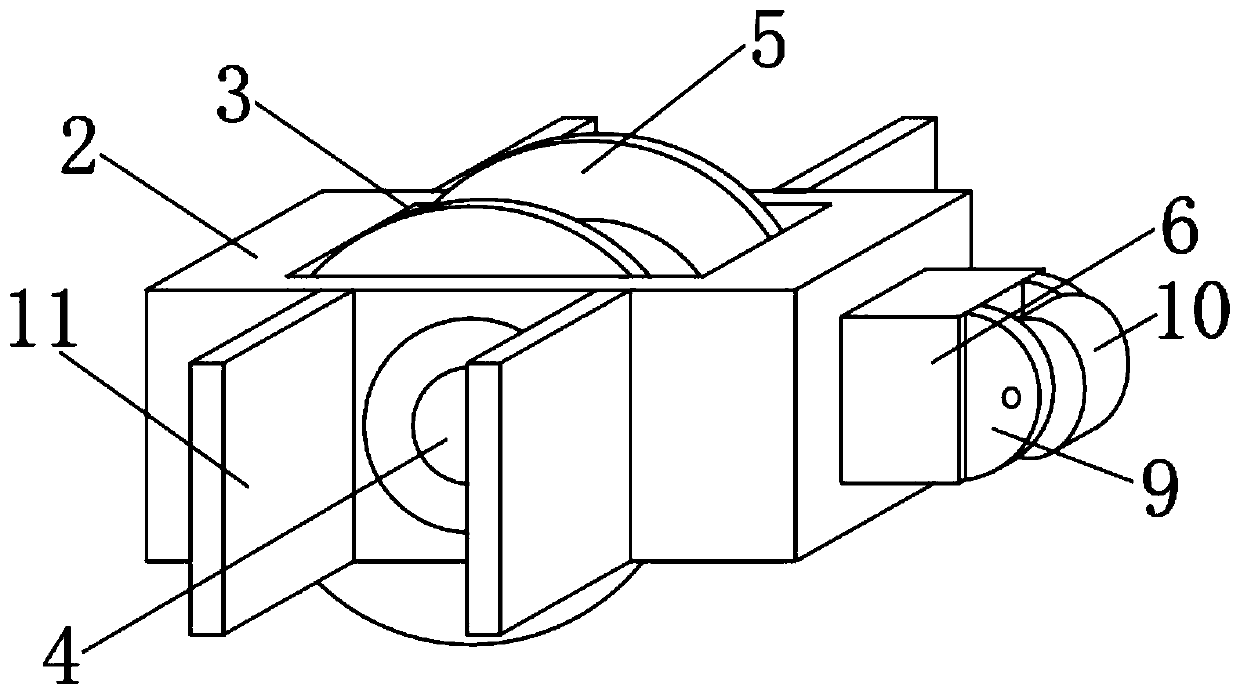

[0027] see Figure 1-5 , a lifting anti-shake device based on hoisting equipment, comprising an installation box 1, an anti-shake frame 2 is arranged in the middle of the installation box 1, an installation groove 3 is opened in the middle of the anti-shake frame 2, and a fixing groove 3 is fixedly connected in the middle of the installation groove 3. Axle 4, fixed shaft 4 side walls are rotatably connected with a rope drive wheel 5, both ends of the anti-shake frame 2 are slidably connected with a sliding column 6, and one end of the sliding column 6 is fixedly connected with a mounting frame 9, and the mounting frame 9 is rotatably connected with a The first support wheel 10, and the first support wheel 10 is supported on the inner wall of the installation box 1, the front and rear ends of the anti-shake frame 2 are fixedly connected with two installation plates 11, and both ends of the installation box 1 are provided with sliding grooves 12. A sliding rod 13 is slidably con...

Embodiment 2

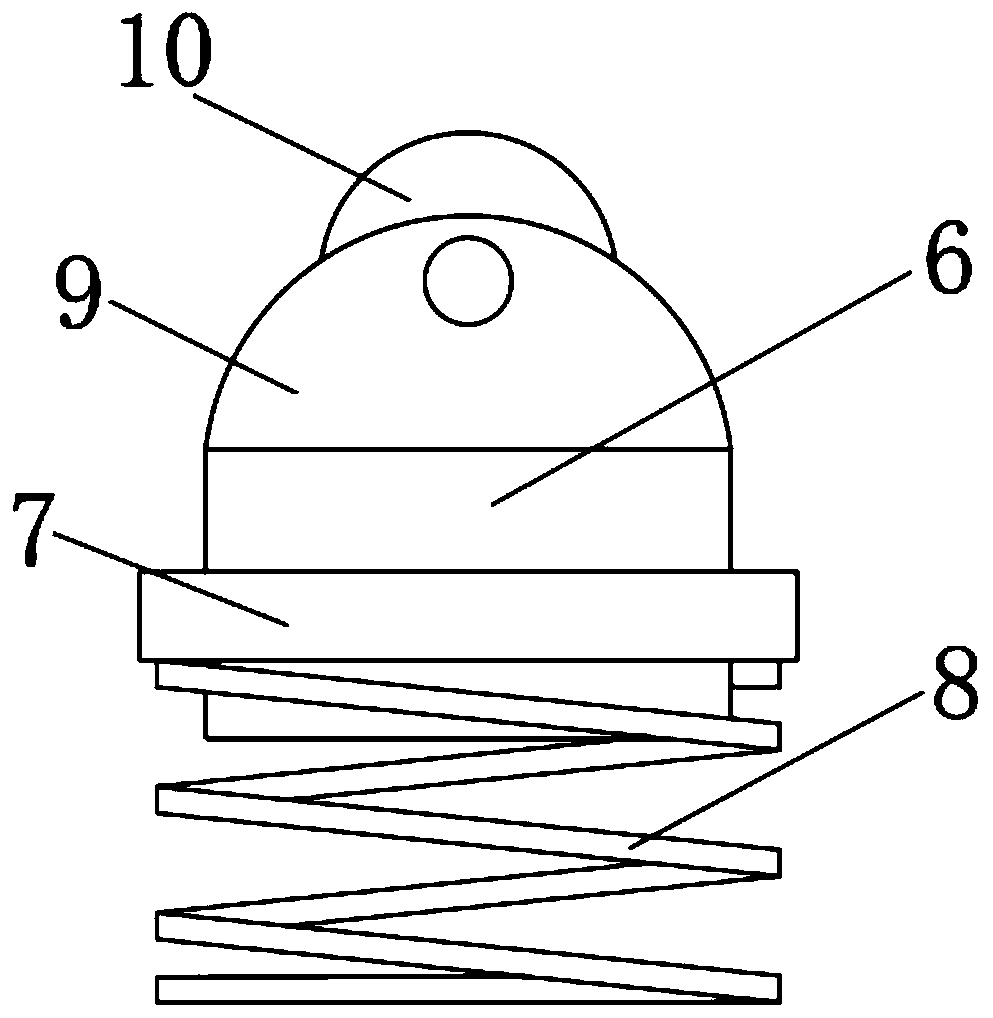

[0030] see Figure 1-5 , on the basis of Embodiment 1, a further improvement is made: the side wall of the sliding column 6 is fixedly connected with a sliding ring 7, and the sliding ring 7 is matched and slidingly connected in the inner chute of the anti-shake frame 2, and one end of the sliding ring 7 is fixedly installed with a first Spring 8; the width of the sliding groove 12 is the same as the diameter of the sliding rod 13, and the sliding rod 13 is matched and slidably connected in the sliding groove 12; the middle part of one end of the connection plate 14 is fixedly connected with a support column 16, and the second spring 15 is located on the side wall of the support column 16 .

[0031] In this embodiment, the sliding ring 7 can ensure the sliding performance of the sliding column 6 in the anti-shake frame 2, and the first spring 8 can be used to support the sliding column 6, so that the first supporting wheel 10 can be used to support the installation box 1 The ...

Embodiment 3

[0033] see Figure 1-5 On the basis of Embodiment 1, a further improvement has been made: the side walls of the sliding rods 13 are fixedly connected with mounting parts 17, the mounting parts 17 are rotatably connected with a turret 18, and the other ends of the turret 18 are rotatably connected with a second Two support wheels 20, and the second support wheels 20 are supported on the two ends of installation box body 1; Turret 18 both sides are all equipped with installation bearing 19, and installation bearing 19 inner walls are connected in the mounting part 17 by rotating shaft rotation; The middle part of the frame 18 is fixedly connected with a connecting plate 21, and one end of the mounting part 17 is fixedly connected with a support plate 22, and the top of the support plate 22 is fixedly equipped with a third spring 23, and the other end of the third spring 23 is fixedly installed on one end of the connecting plate 21.

[0034] In this embodiment, the turret 18 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com