Method for aligning die head bolt

A bolt and die head technology, applied in the field of die head bolt alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

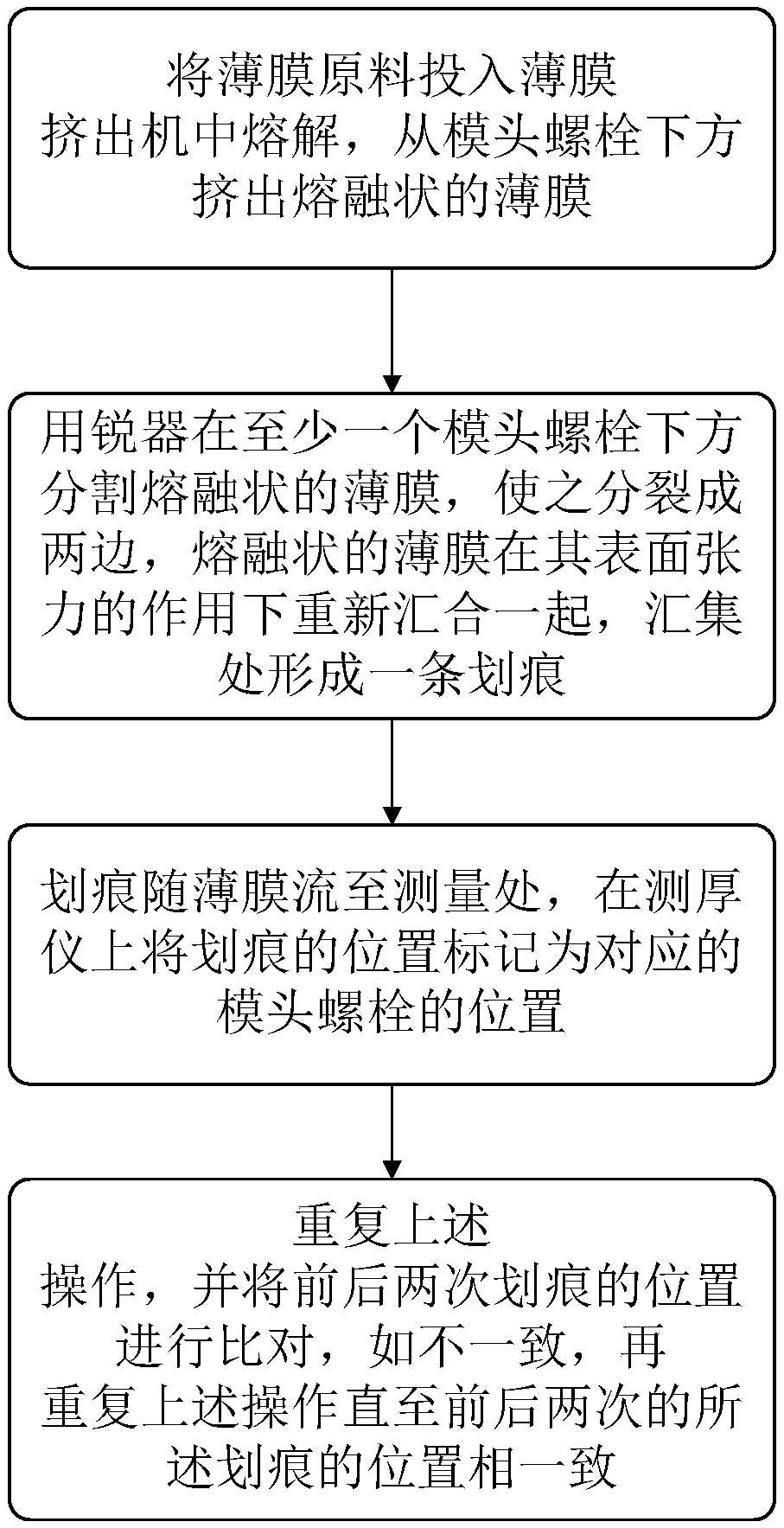

[0020] Please refer to figure 1 , this embodiment provides a method for aligning die head bolts, which is suitable for film extruders that use the stacking method to produce films.

[0021] The film extruder includes a base plate and a plurality of die head bolts, and the film raw material is extruded from the gap between the base plate and the die head bolts after being melted inside the film extruder.

[0022] Alignment methods for die head bolts include:

[0023] Step 1, put the film raw material into the extruder to melt, and then extrude the molten film from the bottom of the die head bolt; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com