mask

A mask, rectangular area technology, applied in the field of masks, can solve the problems of unfavorable mask sag, increasing the complexity of fine metal mask opening, and the need for further research on mask.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

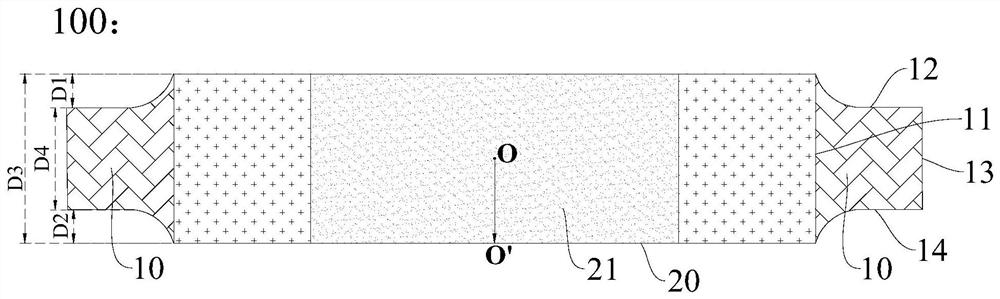

[0046] The schematic diagram of the structure of the fine metal mask is as follows figure 2 As shown, the jaw area 10 includes a sub-jaw area, wherein, D1=D2=10 mm, D1+D2=(0.3~0.4)*D3, the radius of the first arc segment of the second side and the radius of the fourth side The radius of the second arc segment r1=10mm, r1-r2≤20mm, and the length d of the side of the sub-jaw area away from the first side is 10mm-40mm.

Embodiment 2

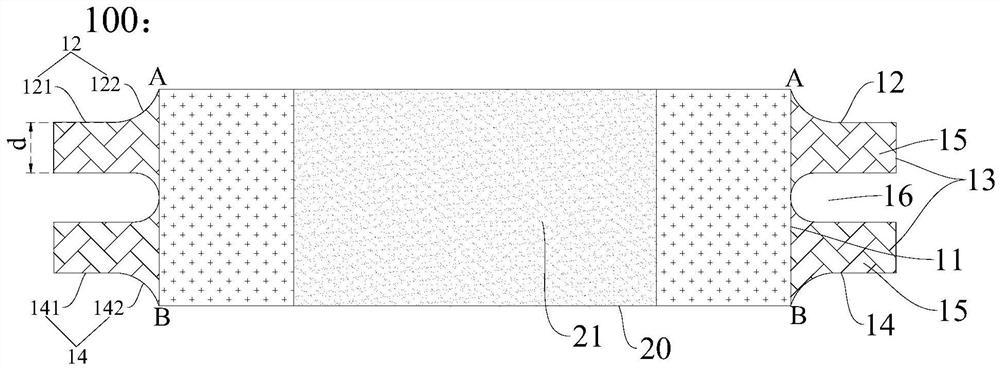

[0051] The schematic diagram of the structure of the fine metal mask is as follows Figure 7 As shown, the jaw area 10 includes two sub-jaw areas, wherein, D1=D2=34.26 mm, D1+D2=(0.3~0.4)*D3, r1=34.26 mm, r1-r2≤20 mm, each sub-clamp The length d of the side length of the claw area away from the first side is 10 mm to 40 mm, wherein the first intersection point A, the second intersection point B and the lowest point of the bottom of the groove are not on the same straight line.

Embodiment 3

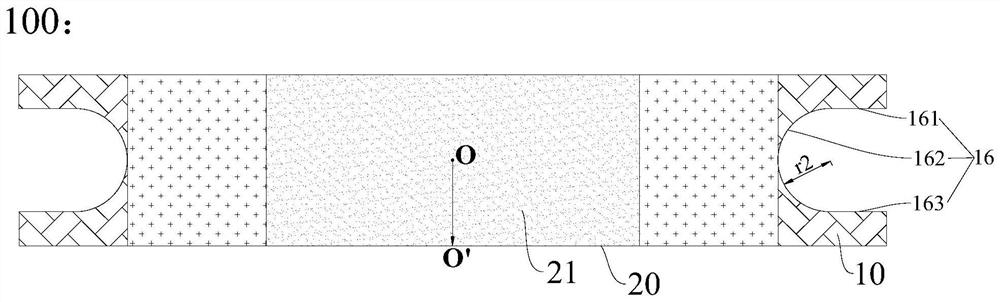

[0053] The schematic diagram of the structure of the fine metal mask is as follows Figure 3-5 As shown, the jaw area 10 includes two sub-jaw areas, wherein, D1=D2=27.13 mm, D1+D2=(0.3~0.4)*D3, r1=27.13 mm, r1-r2≤20 mm, each sub-clamp The length d of the side length away from the first side of the jaw area is 10 mm to 40 mm (and equal to the length d of the side length of each sub-jaw area away from the first side in Embodiment 2), wherein the first intersection point A, The second intersection point B is on the same line as the lowest point of the bottom of the groove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com