Ti-Al-Zr-Cr-series martensitic titanium alloy and preparation method thereof

A titanium alloy and Martensite technology, applied in the field of high-performance alloy materials, can solve problems such as plasticity reduction, achieve low cost, improve coordinated deformation ability, and excellent room temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

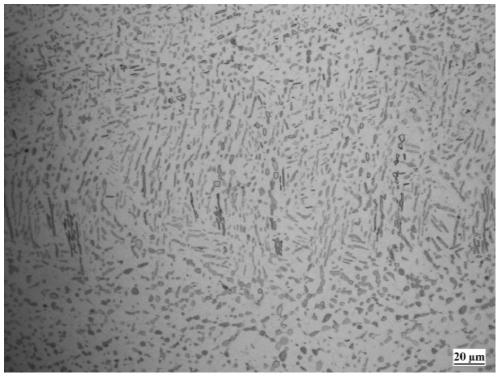

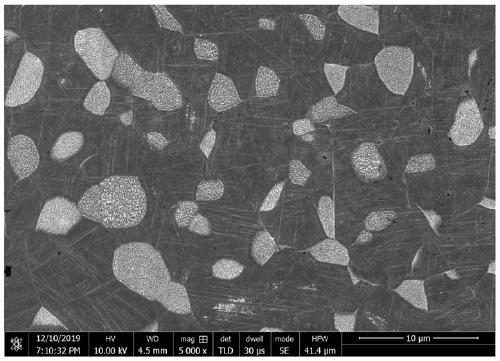

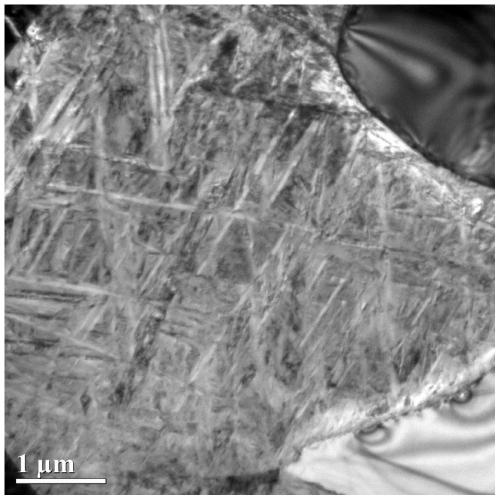

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned Ti-Al-Zr-Cr series martensitic titanium alloy comprises the following steps:

[0029] (1) According to the composition design, select the corresponding raw materials for alloy batching and mix them evenly, and then use the cold crucible suspension melting method (CCLM) to melt the alloy;

[0030] (2) Argon gas is introduced during the melting process, the induction current is 350-400A, and the current frequency is 20-25KHz. After the alloy is completely melted, it is kept for 3-5 minutes, and the ingot is obtained by cooling;

[0031] Specifically, the raw materials are loaded into the furnace in bulk and obtained ingots through five suspension smelting;

[0032] (3) After the ingot has been peeled off and the riser is cut, it is free forged on a hammer (open billet forging and high temperature forging) to obtain Ti-Al-Zr-Cr series martensitic titanium alloy;

[0033] Among them, the blank forging temperature is 1100-1150°C...

Embodiment 1

[0038] A Ti-Al-Zr-Cr martensitic titanium alloy is composed of the following components in weight percentage: 5.15-5.30% of Al, 4.45-4.60% of Zr, 2.65-2.80% of Cr, and the balance is Ti and unavoidable impurities.

[0039] The preparation method is as follows:

[0040] According to the above composition, the alloy was prepared by suspension melting in cold crucible and free forging on hammer. Specifically, high-purity titanium, high-purity aluminum, high-purity zirconium, and high-purity chromium are uniformly mixed according to the proportion and loaded into the furnace in bulk, and then smelted. The process is all carried out in a high-purity argon environment. The frequency is 20-25KHz. In order to ensure uniform composition, the alloy was smelted 5 times, and the ingot was turned upside down before each smelting and loaded into the furnace. After the riser is cut off from the ingot, billet forging and high temperature forging are carried out to obtain Ti-Al-Zr-Cr marten...

Embodiment 2

[0052] A Ti-Al-Zr-Cr martensitic titanium alloy is composed of the following components in weight percent: 5.15 to 5.30% of Al, 4.45 to 4.60% of Zr, 2.65 to 2.80% of Cr, and the balance is Ti and unavoidable impurities.

[0053] The preparation method of Ti-Al-Zr-Cr series martensitic titanium alloy is as follows:

[0054] According to the above composition, the alloy was prepared by suspension melting in cold crucible and free forging on hammer.

[0055] Specifically, high-purity titanium, high-purity aluminum, high-purity zirconium, and TiCr master alloy are uniformly mixed according to the proportion and loaded into the furnace in bulk, and then smelted. The process is all carried out in a high-purity argon environment. The frequency is 20-25KHz. In order to ensure uniform composition, the alloy was smelted 5 times, and the ingot was turned upside down before each smelting and loaded into the furnace. After the riser is cut off from the ingot, billet forging and high tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com