A kind of anti-low temperature foam decontamination agent and preparation method thereof

A detergent, low temperature resistant technology, applied in the fields of botanical equipment and methods, disinfectants, biocides, etc., to achieve remarkable low temperature sterilization performance, excellent practical work performance, and improve efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

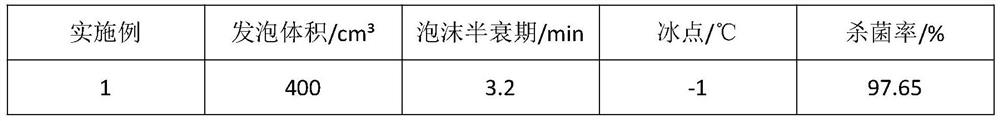

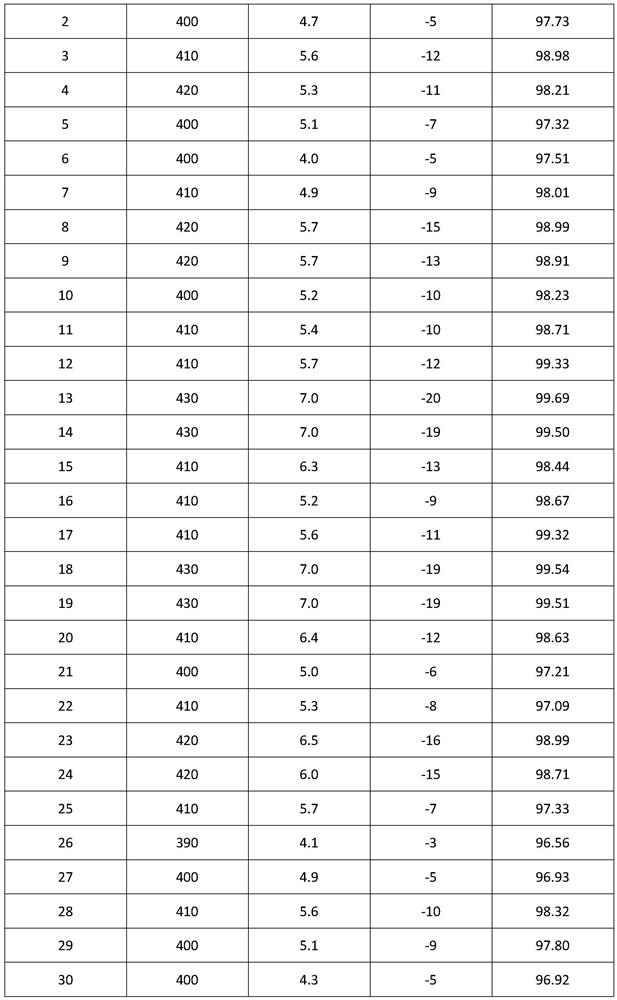

Examples

experiment example

[0066] plan 1

[0067] A kind of preparation of anti-low temperature foam decontamination agent:

[0068] 1. Add 1000 g of deionized water into the reaction vessel.

[0069] 2. Add 387g of propylene carbonate to the container, that is, 20% by mass, and control the temperature in the container to 25° C., and use ultrasonic vibration to stir evenly.

[0070] 3. Add 290g of hydrogen peroxide into the container, that is, 15% by mass, and control the temperature in the container to 25° C., and use ultrasonic vibration to stir evenly.

[0071] 4. Add 15.5g of sodium bicarbonate into the container, that is, 0.8% by mass, and control the temperature in the container to 25°C, and stir evenly with ultrasonic vibration.

[0072] 5. Add 7.8g of sodium lauryl sulfate into the container, that is, 0.4% by mass, and control the temperature in the container to 25° C., and use ultrasonic vibration to stir evenly.

[0073] 6. To prepare the preparation solution, add 0.4 g of sodium silanolate...

Embodiment 1

[0102] A kind of preparation of anti-low temperature foam decontamination agent:

[0103] 1. Add 1000 g of deionized water into the reaction vessel.

[0104] 2. Add 291g of propylene carbonate to the container, that is, 15% by mass, and control the temperature in the container to 25° C., and use ultrasonic vibration to stir evenly.

[0105] 3. Add 194g of hydrogen peroxide into the container, that is, 10% by mass, and control the temperature in the container to 25° C., and use ultrasonic vibration to stir evenly.

[0106] 4. Add 15.5g of sodium bicarbonate into the container, that is, 0.8% by mass, and control the temperature in the container to 25°C, and stir evenly with ultrasonic vibration.

[0107] 5. Add 7.8g of sodium lauryl sulfate into the container, that is, 0.4% by mass, and control the temperature in the container to 25° C., and use ultrasonic vibration to stir evenly.

[0108] 6. To prepare the preparation solution, add 0.4 g of sodium silanolate and 0.4 g of sod...

Embodiment 2

[0112] Preparation of a low-temperature-resistant foam decontamination agent: the preparation process of this embodiment is substantially the same as that of Example 1, the difference being that the propylene carbonate used in this embodiment accounts for 15% by mass, and the hydrogen peroxide used accounts for 15% by mass. 15% of the percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com