Production record data analyzer

A data analysis and actual performance technology, applied in the field of production performance data analysis devices, can solve the problems of lack of realization possibility, suitability of production plan, decline of production simulation prediction accuracy, not necessarily in line with the actual situation of the production site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments will be described below with reference to the drawings. It should be noted that this embodiment mode is merely an example for realizing the present invention, and does not limit the technical scope of the present invention.

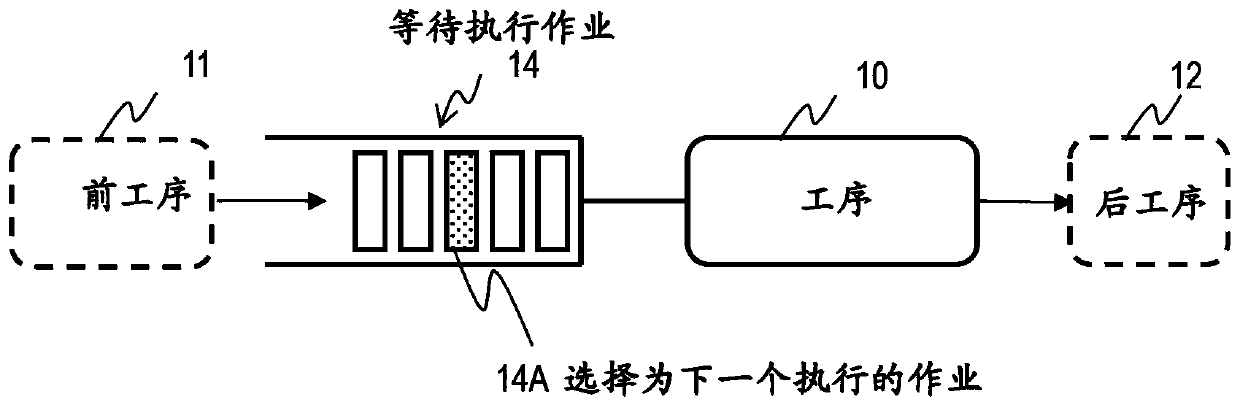

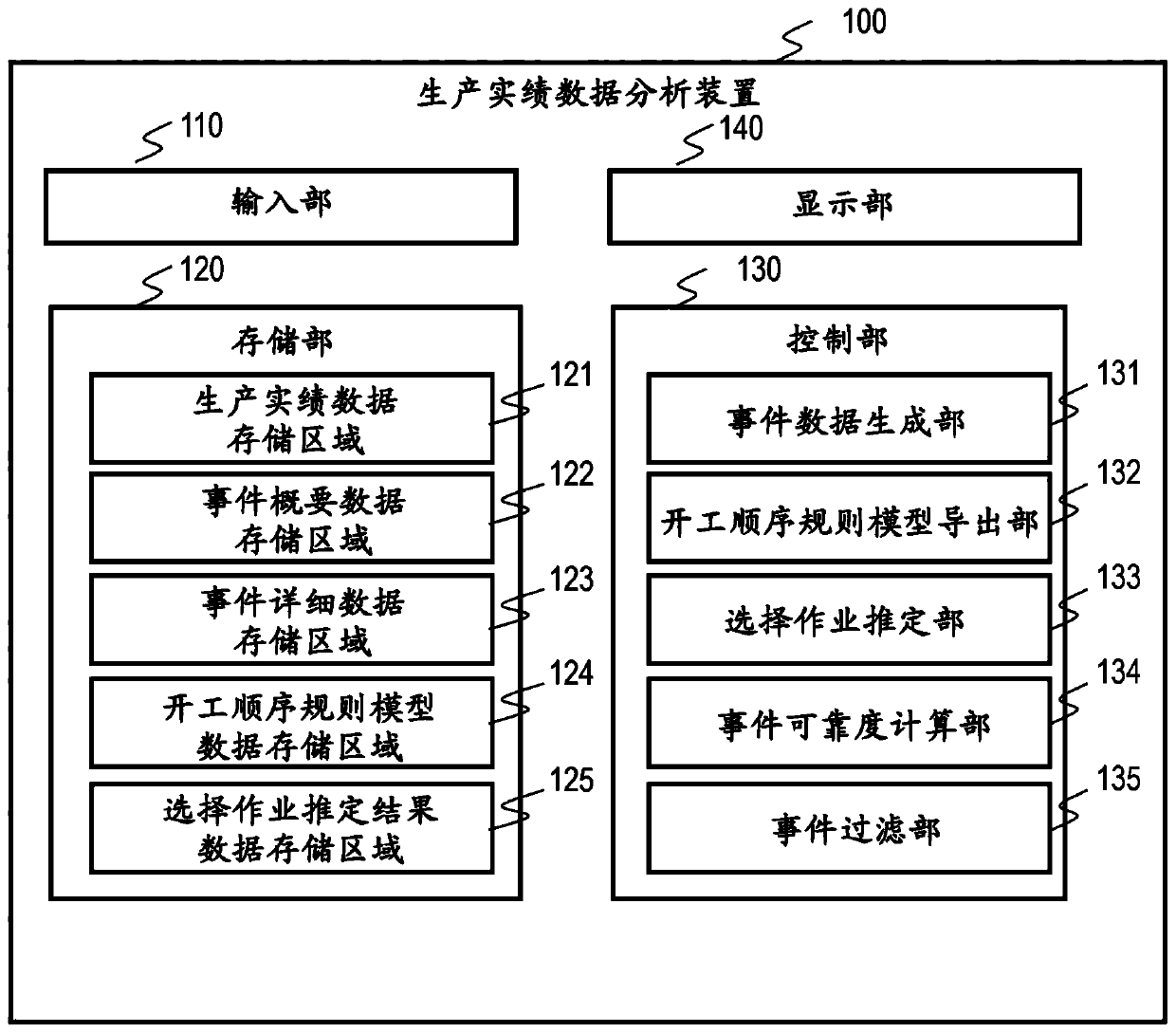

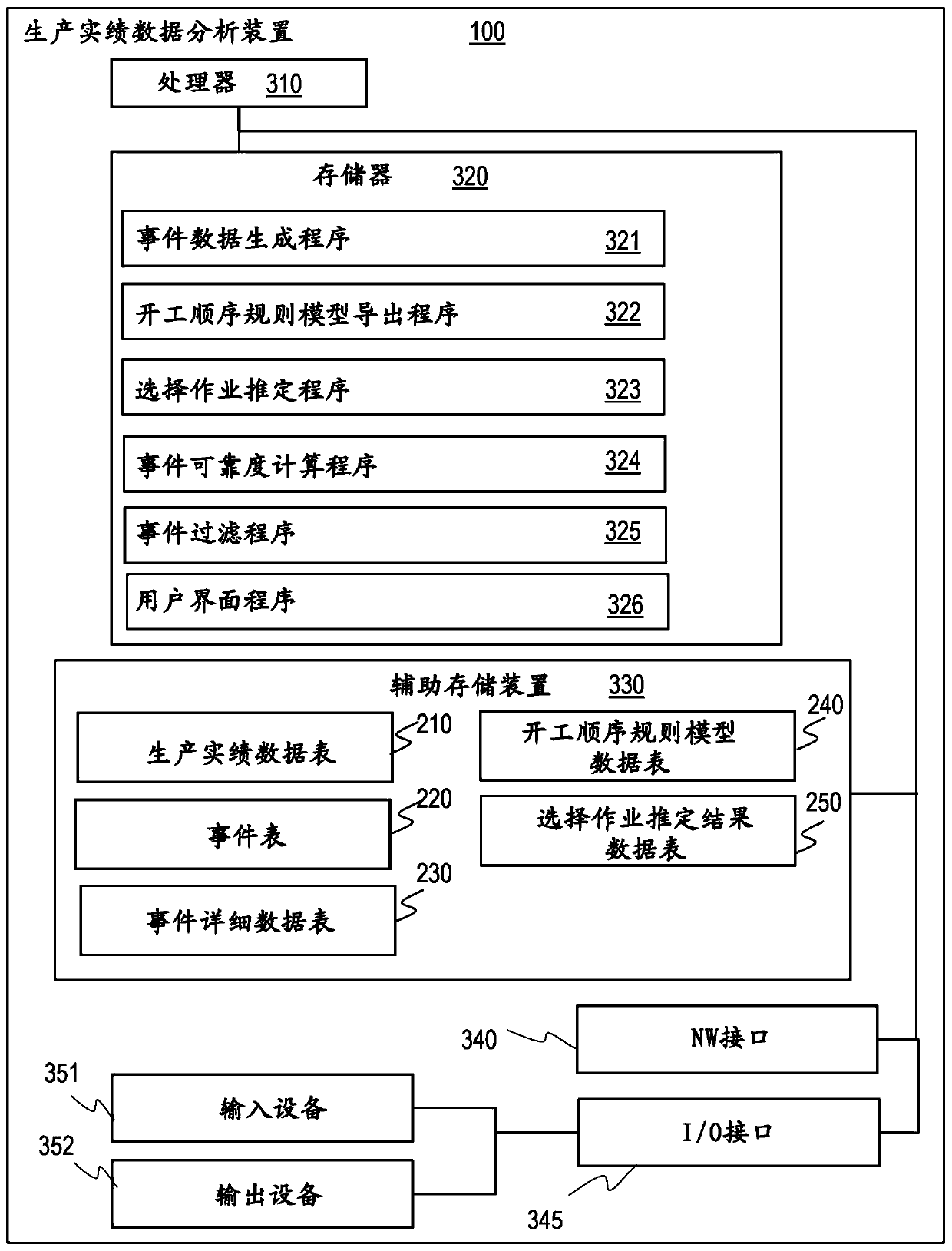

[0023] In one embodiment, the actual production performance data analysis device derives a group of start sequence rule models consisting of a plurality of start sequence rule models for a plurality of processes based on the actual production performance data. The production record data analysis device evaluates the reliability of the next job selection (hereinafter referred to as job selection event or simply event) of each process in the production record using these start sequence rule models. The production performance data analysis device constructs a new production start sequence rule model using production performance data excluding data related to events with low reliability as training data. In this way, it is possible to cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com