Gas water heater capable of achieving multi-stage flow limiting and temperature control and control method thereof

A gas water heater and water heater technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems that users are easily caught by cold, waste tap water, and the heating time of gas water heaters is long, so as to improve the water experience and prevent the water temperature from being too high. High and precise control of hot water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

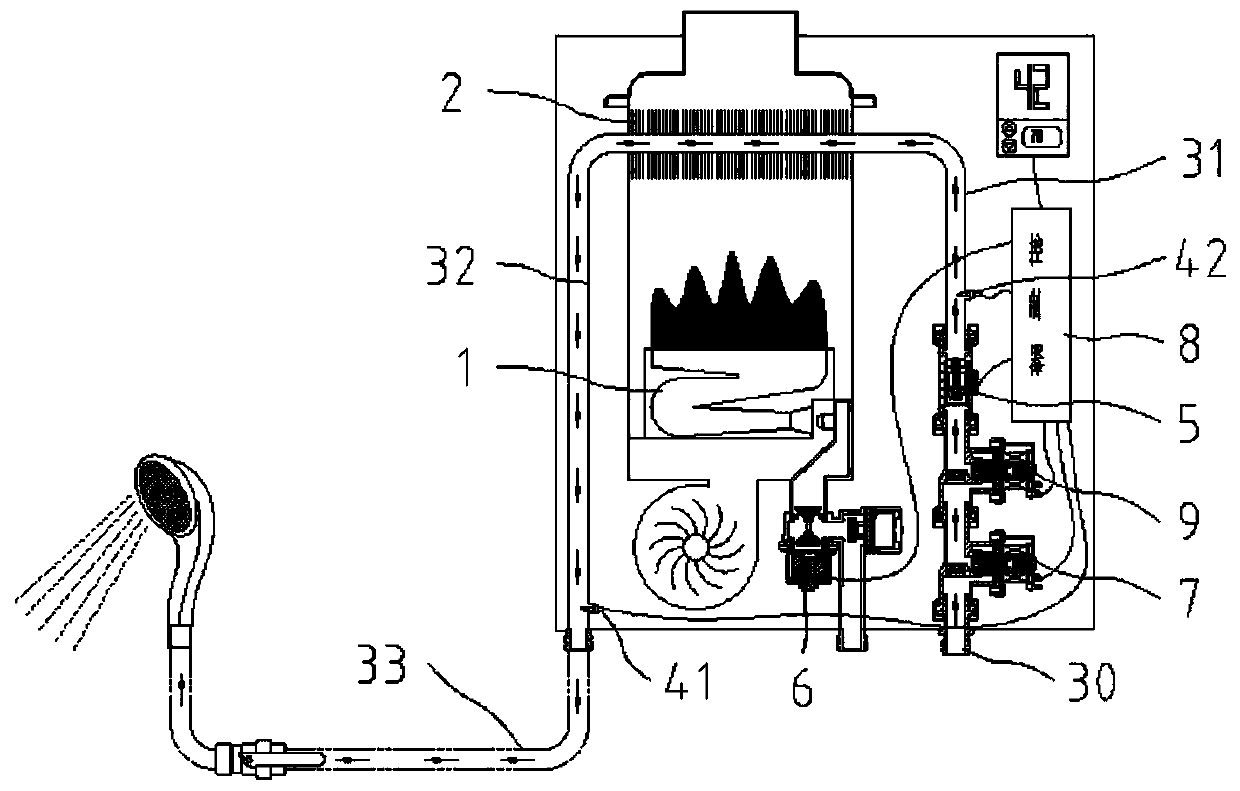

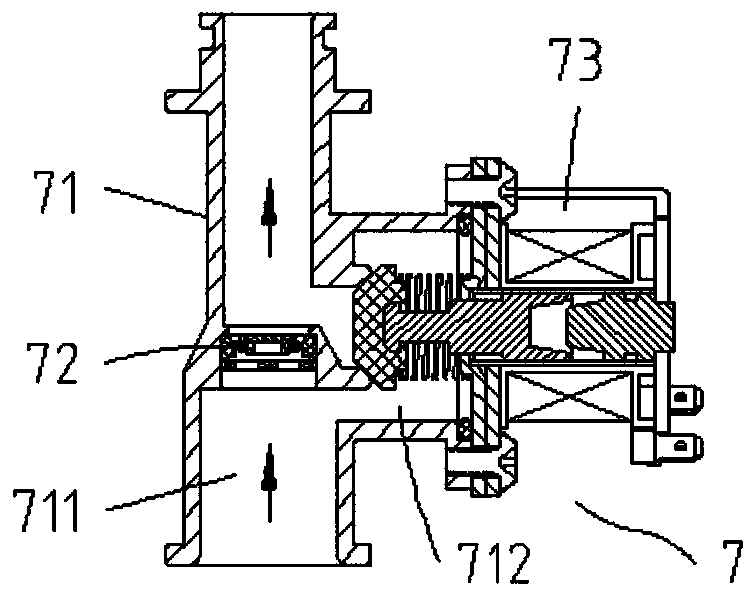

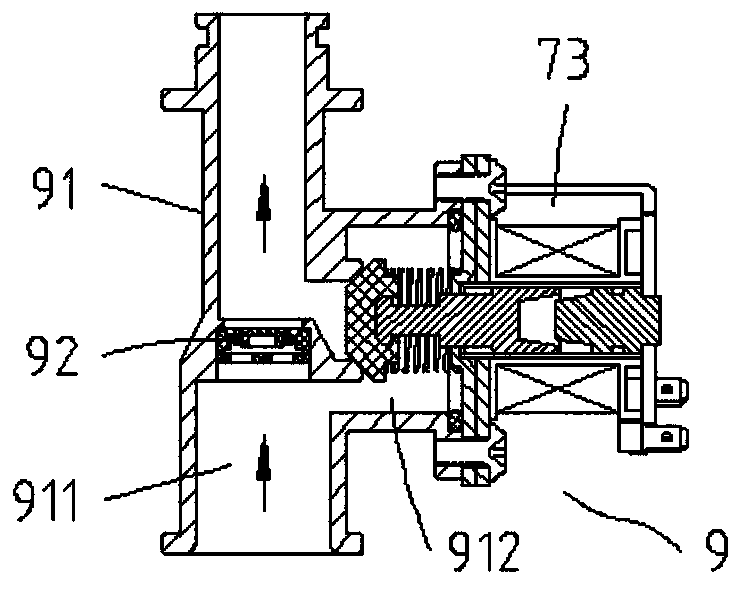

[0051] Such as Figure 1-2 As shown, a gas water heater capable of multi-stage current limiting and temperature control in this embodiment includes a burner 1, a heat exchanger 2, a water inlet pipe 31, a water outlet pipe 32, an outlet water temperature detection device 41, a water flow detection device 5, a gas The proportional valve 6, the first water regulating device 7 and the controller 8, the water inlet end and the water outlet end of the heat exchanger 2 communicate with the water inlet pipe 31 and the water outlet pipe 32 respectively, and the water inlet end of the water inlet pipe 31 communicates with the water inlet joint 30, The water outlet end of the water outlet pipe 32 communicates with the external hot water pipe 33 . The outlet water temperature detection device 41 is arranged on the outlet pipe 32 and is electrically connected with the controller 8 for detecting the outlet water temperature of the outlet pipe 32 in real time. The water flow detection devi...

Embodiment 2

[0063] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that a main current stabilizer 10 is also included. The main flow stabilizer 10 is set in the water inlet joint 30 or in the water inlet end of the first main waterway 711, and the flow limit value of the main flow stabilizer 10 is the maximum water flow of the water heater, and other components are the same as in the first embodiment. In this embodiment, the main flow stabilizer 10 is disposed in the water inlet joint 30 for controlling the maximum water flow of the water heater.

[0064] It can be seen that by adding the main flow stabilizer 10 for controlling the maximum water flow of the water heater in the water inlet joint 30, the maximum water flow of the water heater is more stable, which is beneficial to accurately control the water flow of the water heater, and avoids excessive tap water supply pressure. Affect the constant temperature of the water heater to produce hot wat...

Embodiment 3

[0066] The difference between this embodiment and Embodiment 1 is that the second water regulating device 9 is omitted, and other parts are the same as Embodiment 1. When the first bypass waterway 712 is closed, the flow of water is limited by the first flow stabilizer 72 of the first water regulating device 7, and the water heater is in the primary water flow gear, that is, the minimum water flow gear; when the first bypass When the waterway 712 is opened, the flow of water is not limited by the first flow stabilizer 72 of the first water regulating device 7, and the water heater is at the secondary water flow gear, that is, the maximum water flow gear.

[0067] It can be seen that by omitting the first water regulating device 7 or the second water regulating device 9, while realizing multi-level control of water flow, it is beneficial to reduce the manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com