Press-fitting fixture for special-shaped combined magnet

A magnet and special-shaped technology, applied in the direction of material gluing, inductor/transformer/magnet manufacturing, connecting components, etc., can solve the problem of low efficiency of press-fitting tooling, achieve high production efficiency, meet large-scale mass production, and product consistency good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

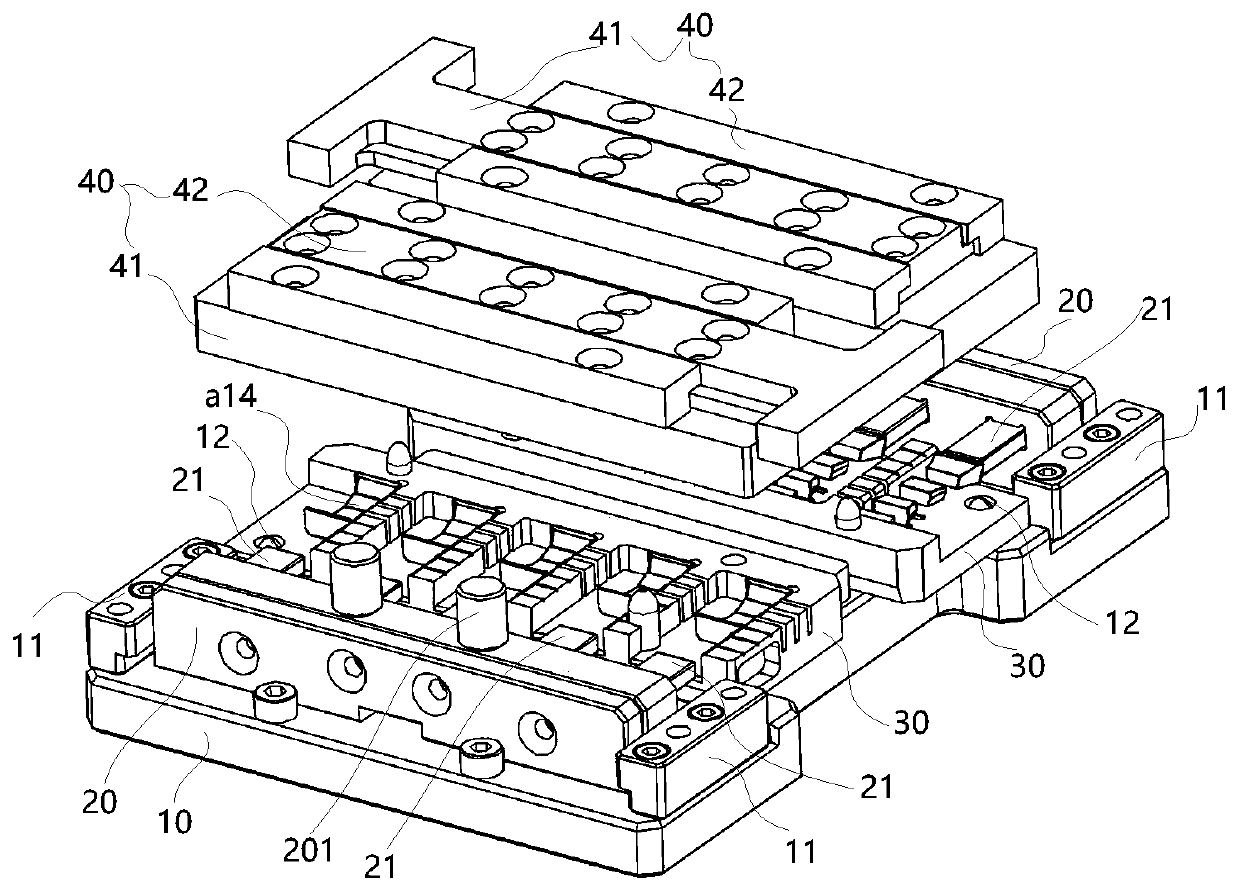

[0019] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

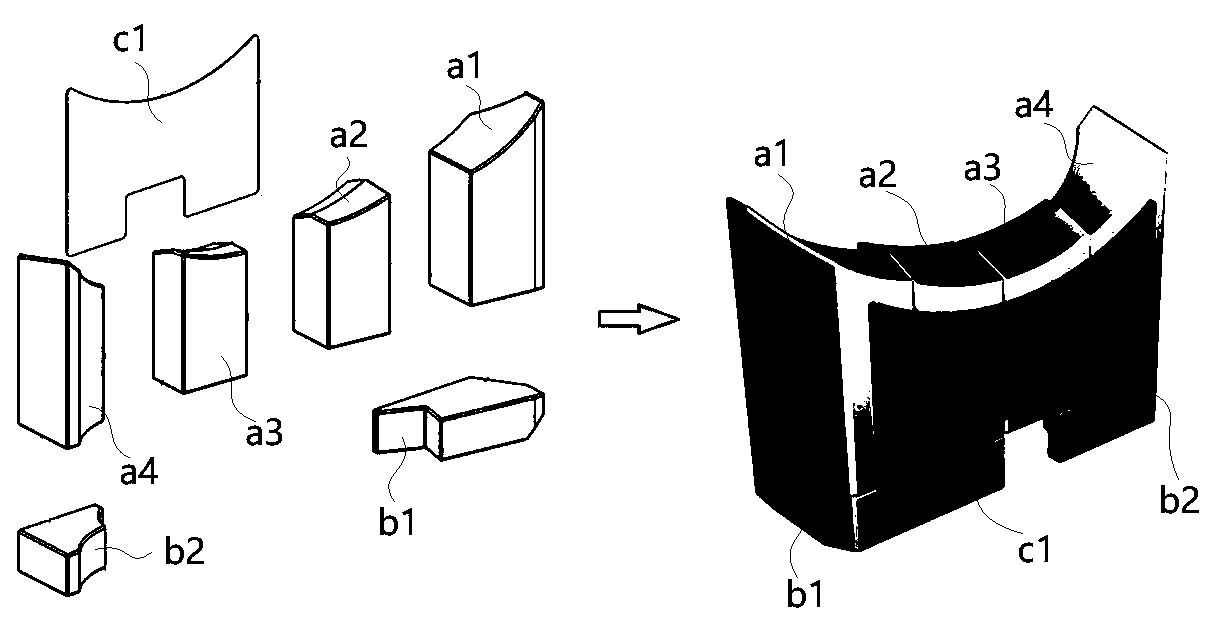

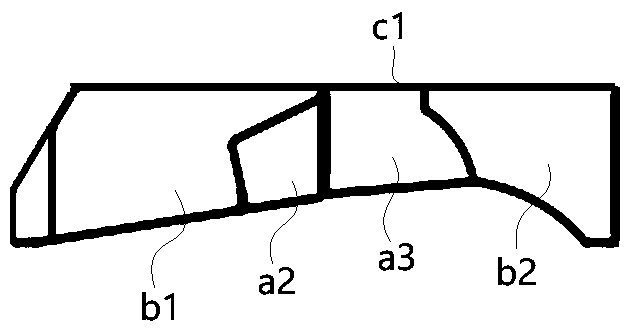

[0020] The structure of the special-shaped composite magnet assembled by the pressing tooling for the special-shaped composite magnet in the embodiment of the present invention is as follows figure 1 As shown, the special-shaped combined magnet is composed of four special-shaped magnet blocks a1, a2, a3, a4, two special-shaped iron blocks b1, b2, and patch c1, which are composed of seven parts. The magnet blocks a1, a2, a3, a4 are bonded and compressed to form the first special-shaped composite magnet a14, and then two pieces of special-shaped iron blocks b1, b2 are bonded and pressed on the bottom of the first special-shaped composite magnet to form the second special-shaped composite magnet , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com