Adjustable reed switch bending device

A bending device and reed switch technology, applied in the field of adjustable reed switch bending devices, can solve the problems of operation limitation, low production efficiency and high cost, and achieve the advantages of reducing operation difficulty, improving production efficiency and reducing errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

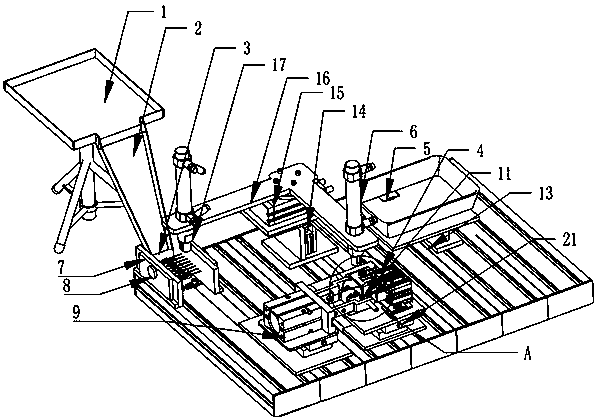

[0034] figure 1 , 2 , 3, 4, 5, and 6, the reed switch shaping equipment includes a feeding device, a positioning device, a manipulator for transferring the reed switch, a shaping device, and an adjustment platform group.

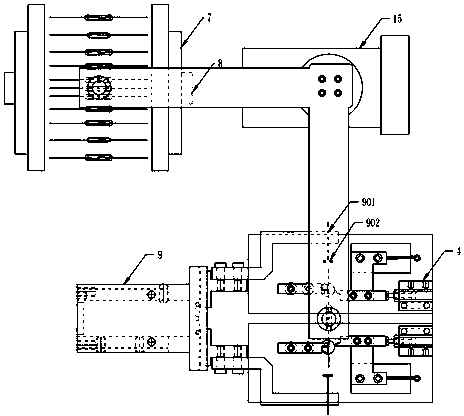

[0035] The discharge device includes a slideway 2, a material preparation tray 1 located at the upper end of the slideway 2, and a material feeding channel 3 located at the lower end of the slideway 2. The material feeding channel is a magnetic levitation material channel, including two fixed material plates, which are adsorbed on the outside of the fixed material plate. The magnetic plate 7, the reinforcing magnetic block 8 adsorbed on the outer middle of the magnetic plate 7.

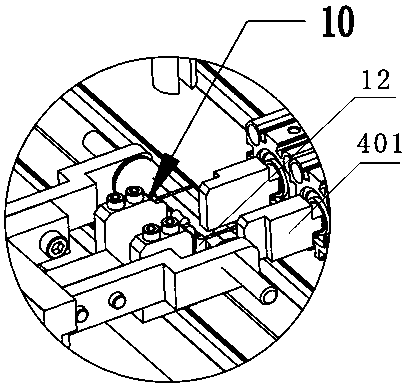

[0036] The positioning device includes a pilot cylinder 9, which is a pneumatic finger, and a positioning seat 10 is arranged between the fingers of the pilot cylinder 9. There are two positioning seats 10, which correspond to the two pins of the reed switch respectively. The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com