Long-distance steel box girder dragging system crossing existing line

A steel box girder, long-distance technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as affecting construction progress, endangering construction safety, and difficulty in connection, reducing coordination difficulty, increasing service life, The effect of reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the described embodiments are some, not all, embodiments of the present invention. The specific embodiments described here are only used to explain the present invention, but not to limit the present invention. All other embodiments obtained by those skilled in the art based on the described embodiments of the present invention belong to the protection scope of the present invention.

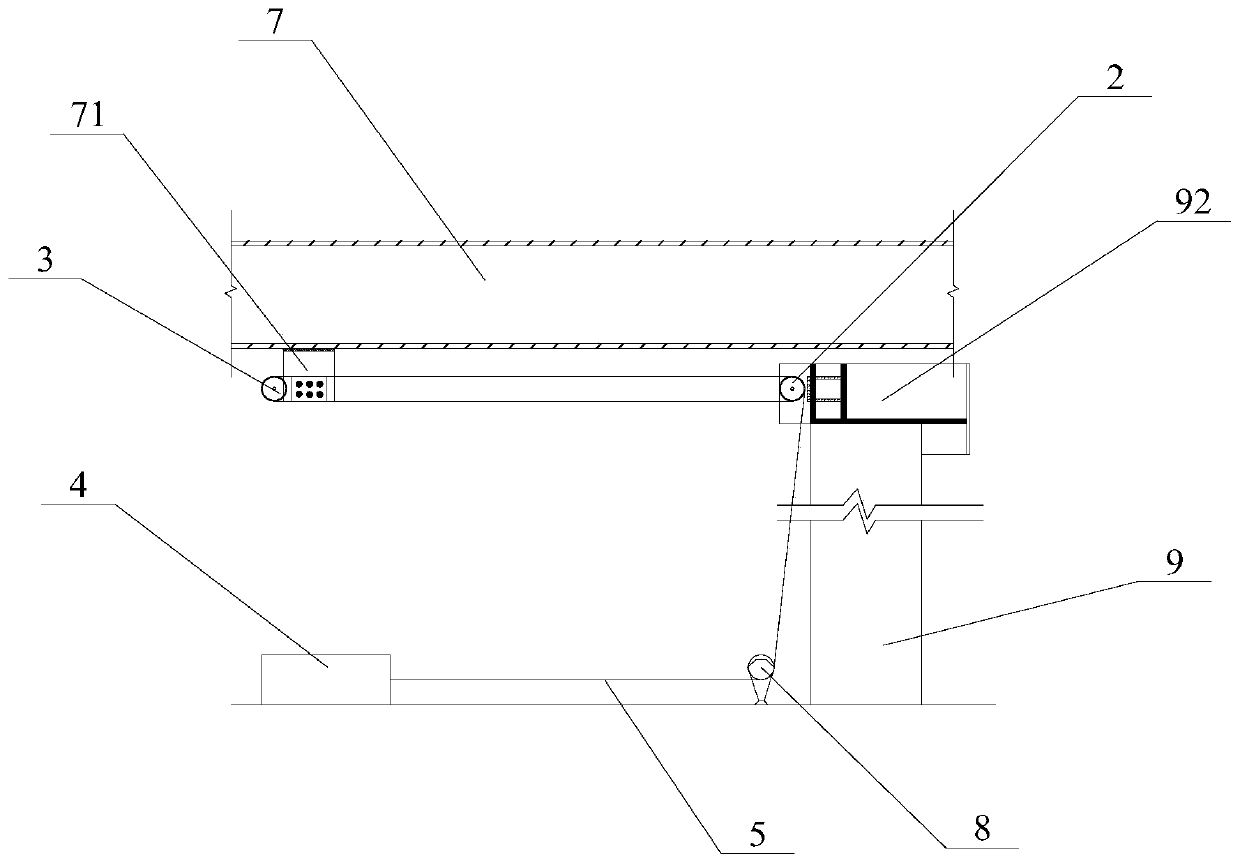

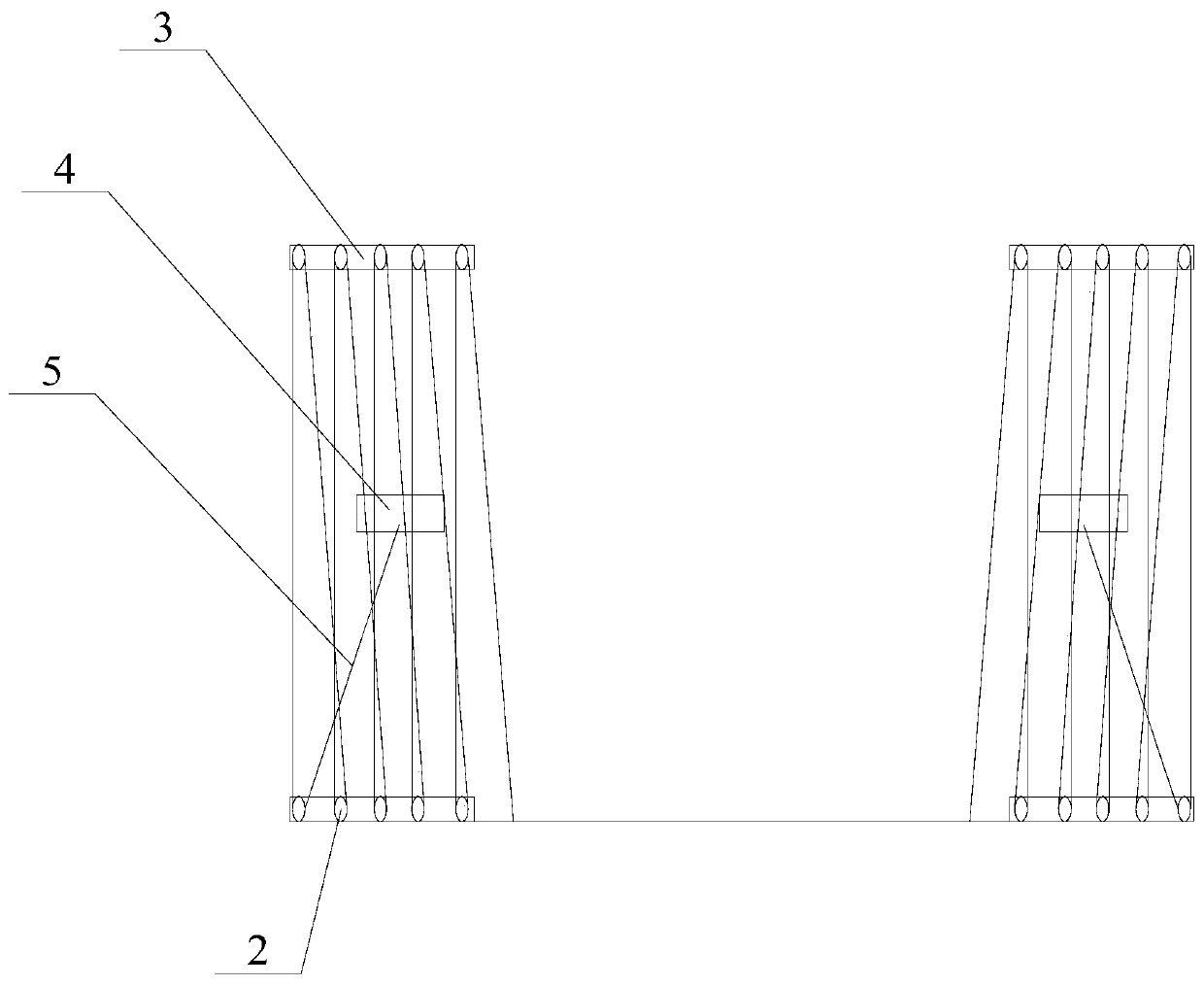

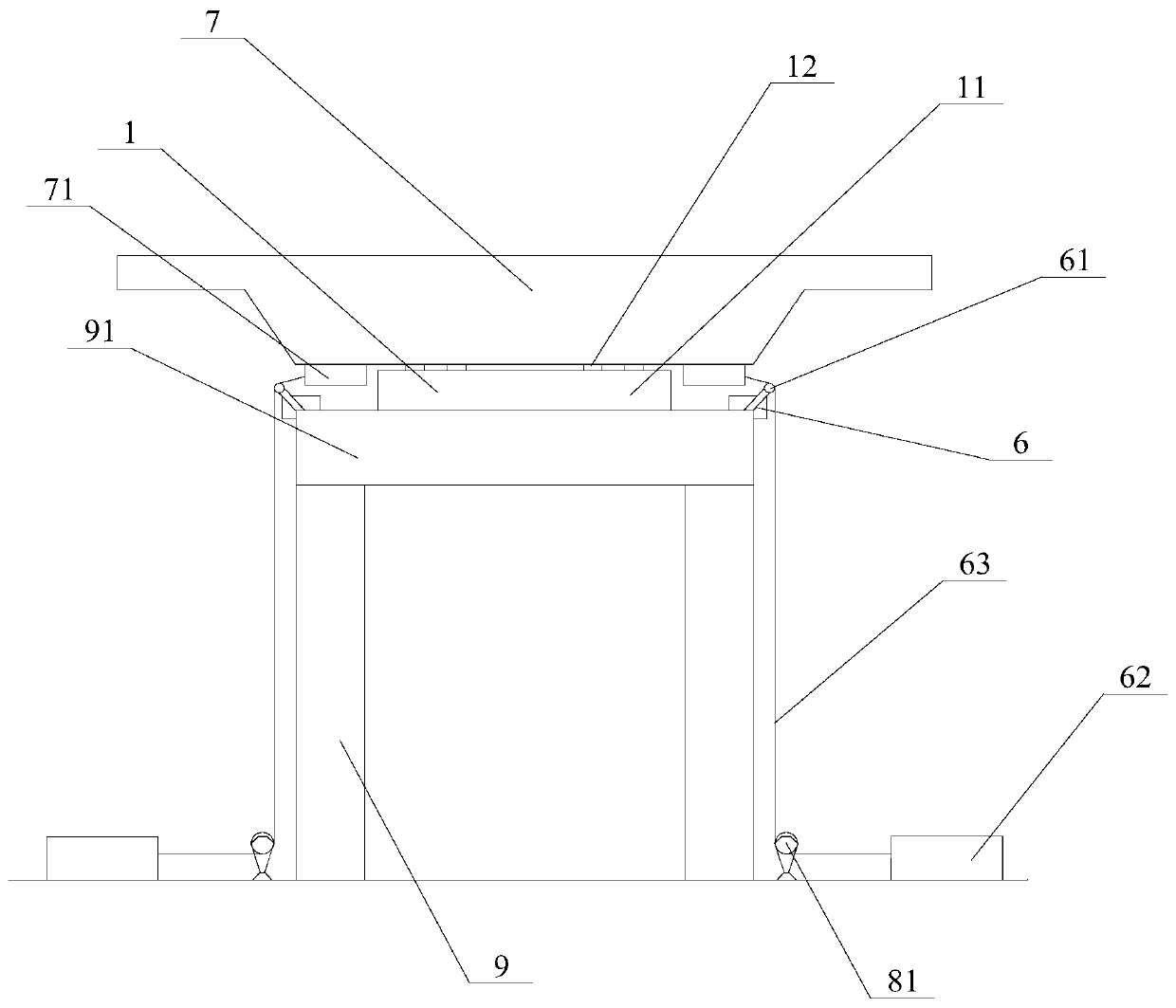

[0024] combine figure 1 and image 3 As shown, the long-distance steel box girder pulling system across the existing line provided by the embodiment of the present application includes a supporting device, a pulling device and a deviation correction device. The support device includes a rolling device 1 arranged on the support sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com