Clamping and conveying mechanism for packaging bag

A packaging bag and pinch belt technology, which is applied in the field of pinch mechanism of packaging bags, can solve the problems that the sealing process cannot be completed smoothly, the clamping seat cannot be guaranteed to be fully synchronized, and the layout space is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

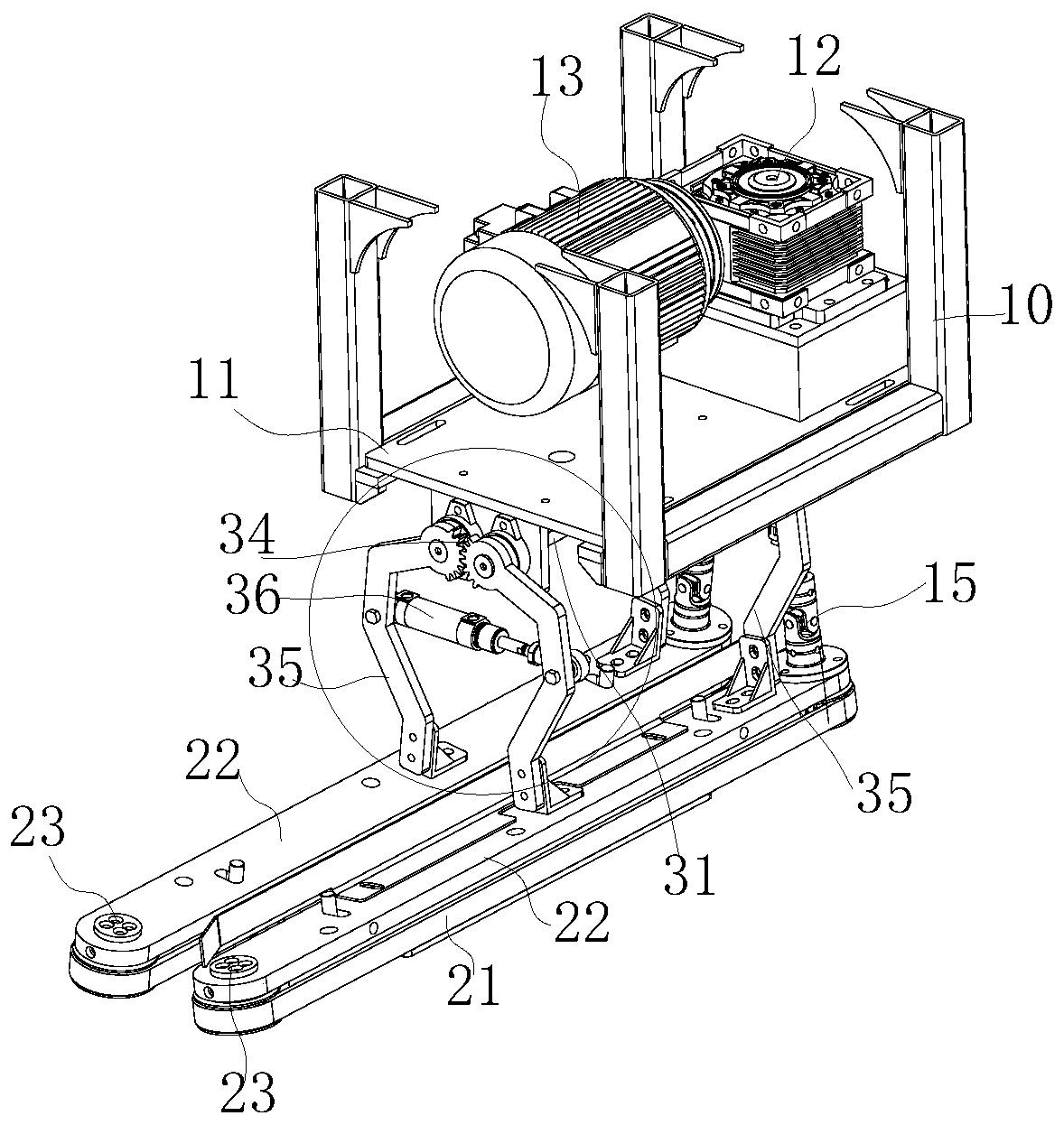

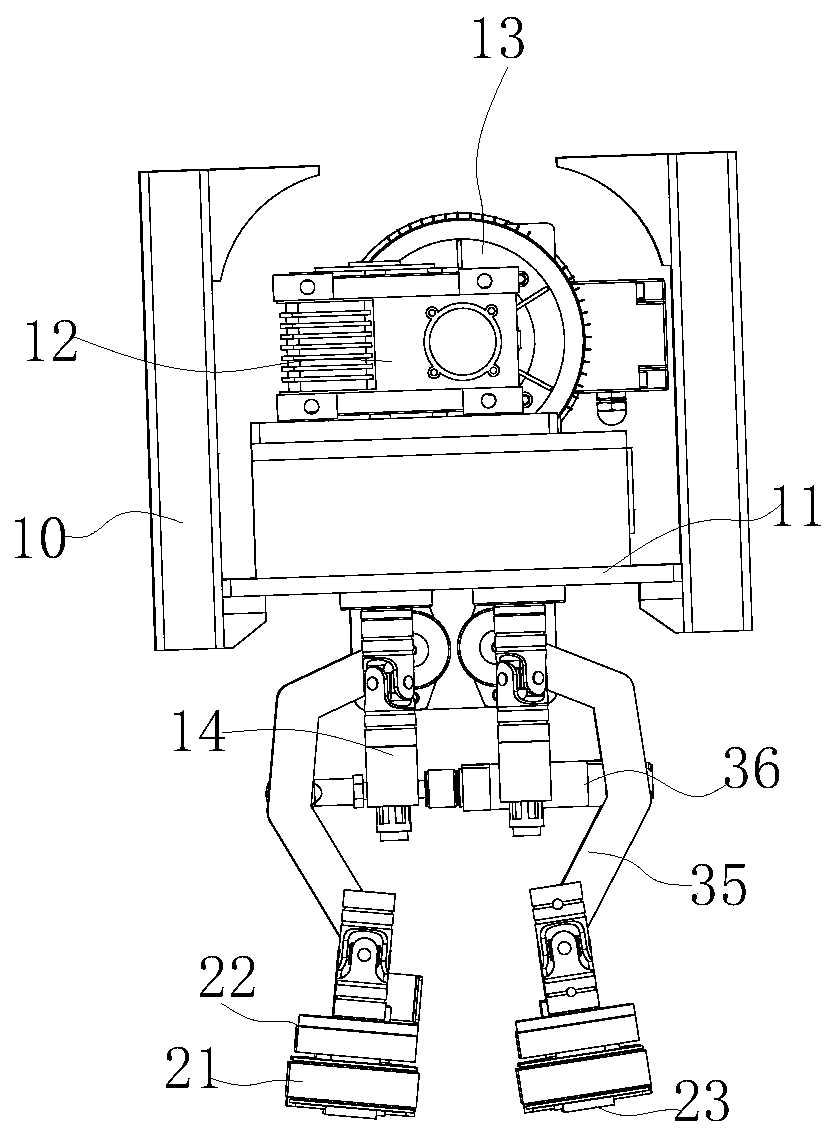

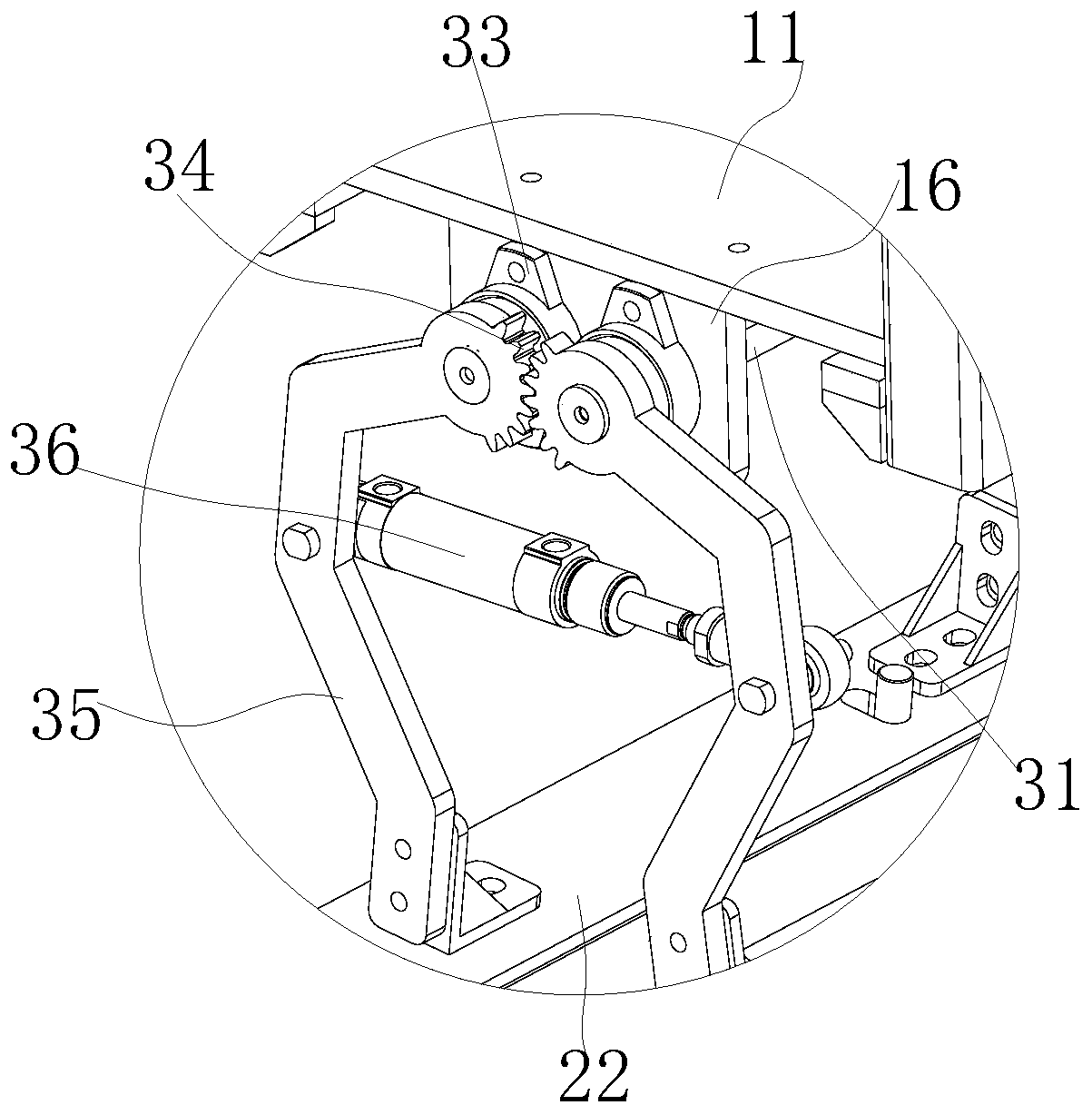

[0009] like Figure 1-Figure 3 As shown, a pinching mechanism for a packaging bag, two groups of pinching belts 21 are arranged at the same height on the frame 10, and the swing arm 35 connected to the pinching belt 21 forms a rotation fit with the frame 10 through a rotating shaft 31, and the rotating shaft 31 The direction of the shaft core is consistent with the feeding direction of the packaging bag, and the power drives the rotating shaft 31 to rotate to drive the two groups of pinch belts 21 to swing to the pinch position close to each other or the bag intake position far away from each other. The belt surfaces of the belts 21 are parallel to each other and are all located in the vertical plane. The adjacent belt surfaces at this position form a belt-shaped constraint area, and the length direction of the belt-shaped constraint area is consistent with the belt-feeding direction of the packaging bag. At the beginning, the power drives the rotating shaft 31 to rotate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com