Atomizer

A technology of nebulizer and atomizing hole, which is applied in the field of nebulizer, and can solve the problem of high temperature of ultrasonic atomizing sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

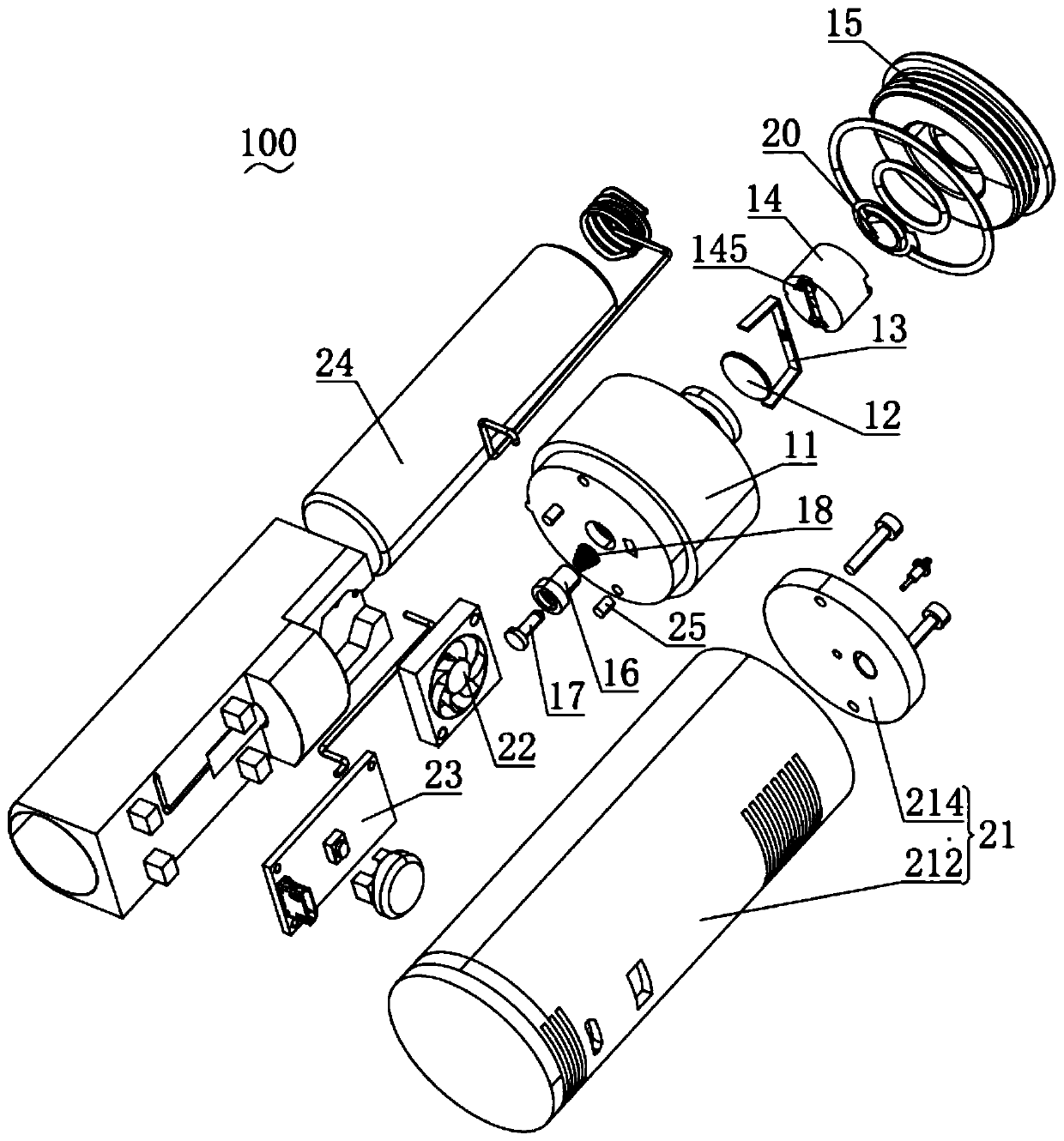

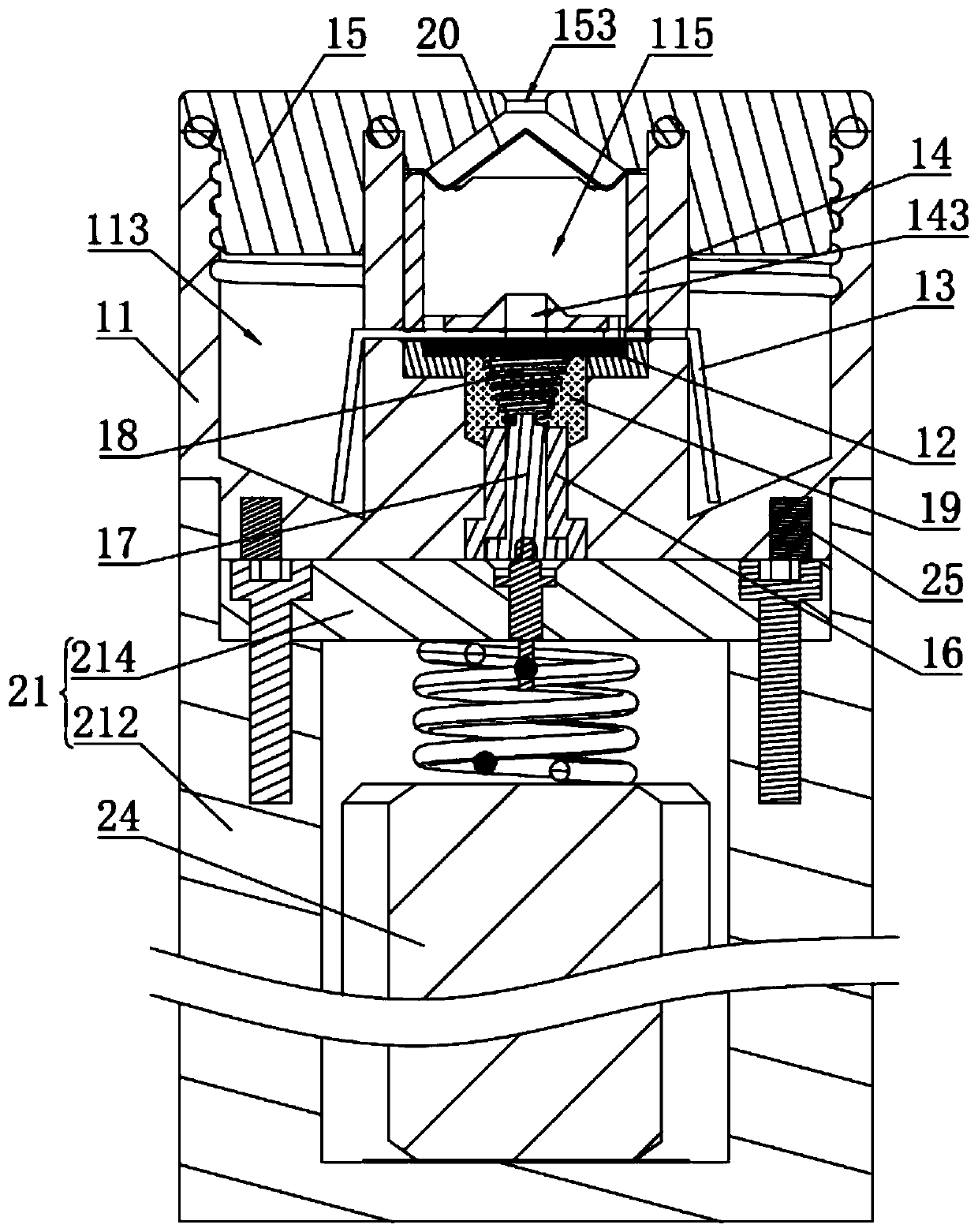

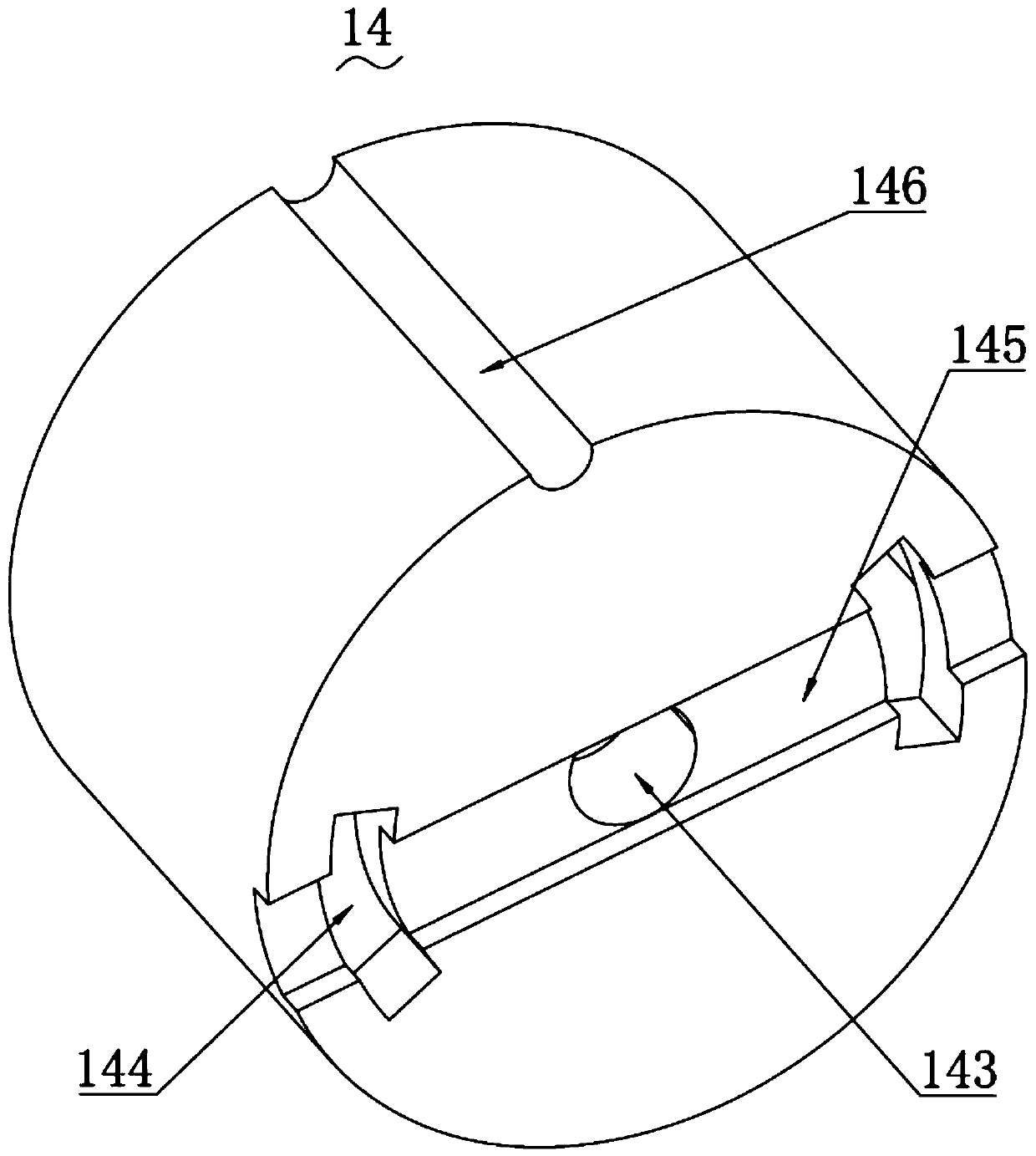

[0030] see figure 1 , figure 2 with image 3 , figure 1 It is a schematic diagram of the exploded structure of the atomizer 100 provided by the present invention, figure 2 It is a schematic cross-sectional structure diagram of the atomizer 100 provided by the present invention at a first viewing angle, image 3 It is a structural schematic diagram of the cooling block 14 provided by the present invention.

[0031] An atomizer 100 of the present invention, the atomizer 100 can atomize liquids such as essential oil, water, perfume, smoke oil and the like. The atomizer 100 includes a liquid stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com