Composite material and its preparation method and quantum dot light-emitting diode

A composite material and graphene technology, applied in the field of materials, can solve problems such as unsatisfactory hole transport performance, and achieve the effects of improved luminous efficiency and display performance, good conductivity and stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

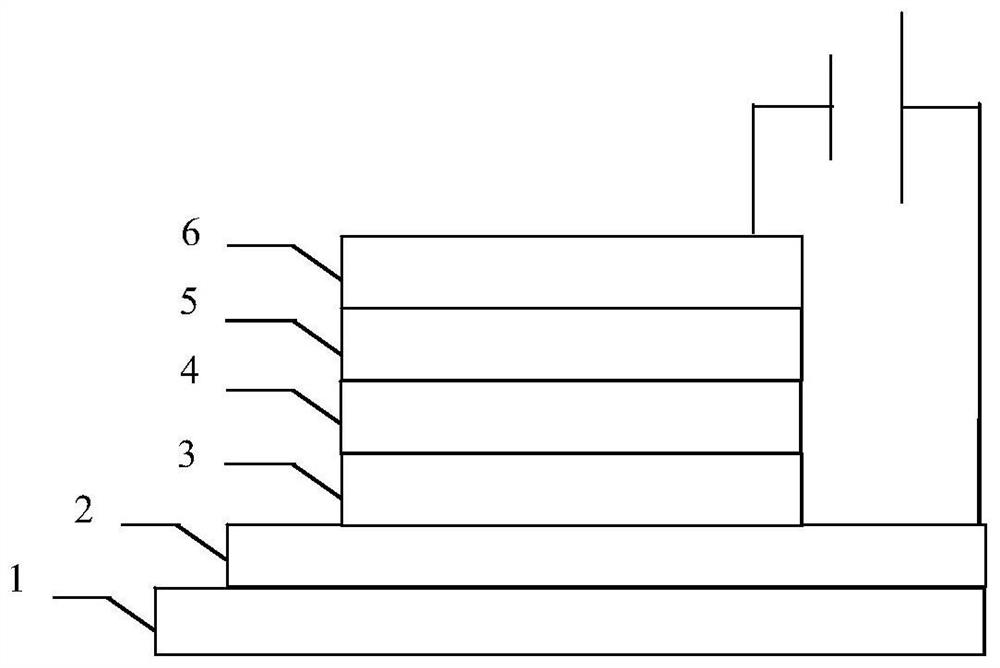

Image

Examples

preparation example Construction

[0026] On the other hand, the embodiment of the present invention also provides a method for preparing a composite material, comprising the following steps:

[0027] S01: Provide dopamine and graphene oxide;

[0028] S01: dissolving the dopamine and graphene oxide in a first solvent, and performing a first heat treatment to obtain graphene oxide with dopamine bound to its surface;

[0029] S03: dissolving the graphene oxide and nickel oxide with dopamine bound on the surface in a second solvent, and performing a second heat treatment to obtain a precursor solution;

[0030] S04: Deposit the precursor solution on the substrate, and perform annealing treatment to obtain the composite material.

[0031]The preparation method of the composite material provided by the embodiment of the present invention is a sol-gel method. First, dopamine and graphene oxide are dissolved in a solvent and heated, so that the amino terminal of dopamine is connected to the surface of graphene oxide ...

Embodiment 1

[0054] Take the use of nickel acetate, ethylene glycol, graphene oxide, sodium hydroxide, and dopamine as examples to introduce in detail.

[0055] (1) Preparation of graphene oxide: Add 1g of graphite powder, 0.5g of sodium nitrate and 3g of potassium permanganate to 23ml of concentrated sulfuric acid successively, and stir for 2h in an ice-water bath (the temperature is kept below 10°C); subsequently, heat up to 35°C, continue to stir for 30min, slowly add 150ml of deionized water; heat to 95°C, keep stirring for 30min, then add 30% hydrogen peroxide (15mL), filter while hot; and wash with 5% HCl solution and deionized water until there is no The filter cake is finally dried until sulfate is detected.

[0056] (2) An appropriate amount of dopamine was dissolved in 5 ml of ethylene glycol to form a solution with a concentration of 0.2M.

[0057] (3) Graphene oxide was dissolved in 10 ml of ethylene glycol, and ultrasonically dispersed at room temperature for 30 min to form a...

Embodiment 2

[0062] Take the use of nickel nitrate, ethanol, graphene oxide, potassium hydroxide, and dopamine as examples to introduce in detail.

[0063] (1) Preparation of graphene oxide: same as Example 1.

[0064] (2) An appropriate amount of dopamine was dissolved in 5 ml of ethanol to form a solution with a concentration of 0.2M.

[0065] (3) Graphene oxide was dissolved in 10 ml of ethanol, and ultrasonically dispersed at room temperature for 30 min to form a uniformly dispersed brown suspension (a solution with a concentration of 0.5 M). After uniformly mixing the brown suspension with an appropriate amount of dopamine solution (molar ratio, graphene oxide:dopamine=3:1), heat preservation at 70° C. for 5 hours to form precursor solution A.

[0066] (4) Dissolve nickel nitrate in 50ml of ethanol to form a transparent solution with a concentration of 0.5M. It was then dissolved with stirring at 70°C. Next, potassium hydroxide was dissolved in 10ml ethanol, stirred and dissolved at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com