Method for judging peeling position of rolling bearing

A judging method and technology of rolling bearings, which are applied in the testing of measuring devices, instruments, and mechanical components, etc., can solve the problems affecting the normal operation, maintenance and repair of equipment, the inability to accurately simulate the vibration signal of bearings, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following is a detailed description of the technical solution of the present invention in conjunction with the accompanying drawings.

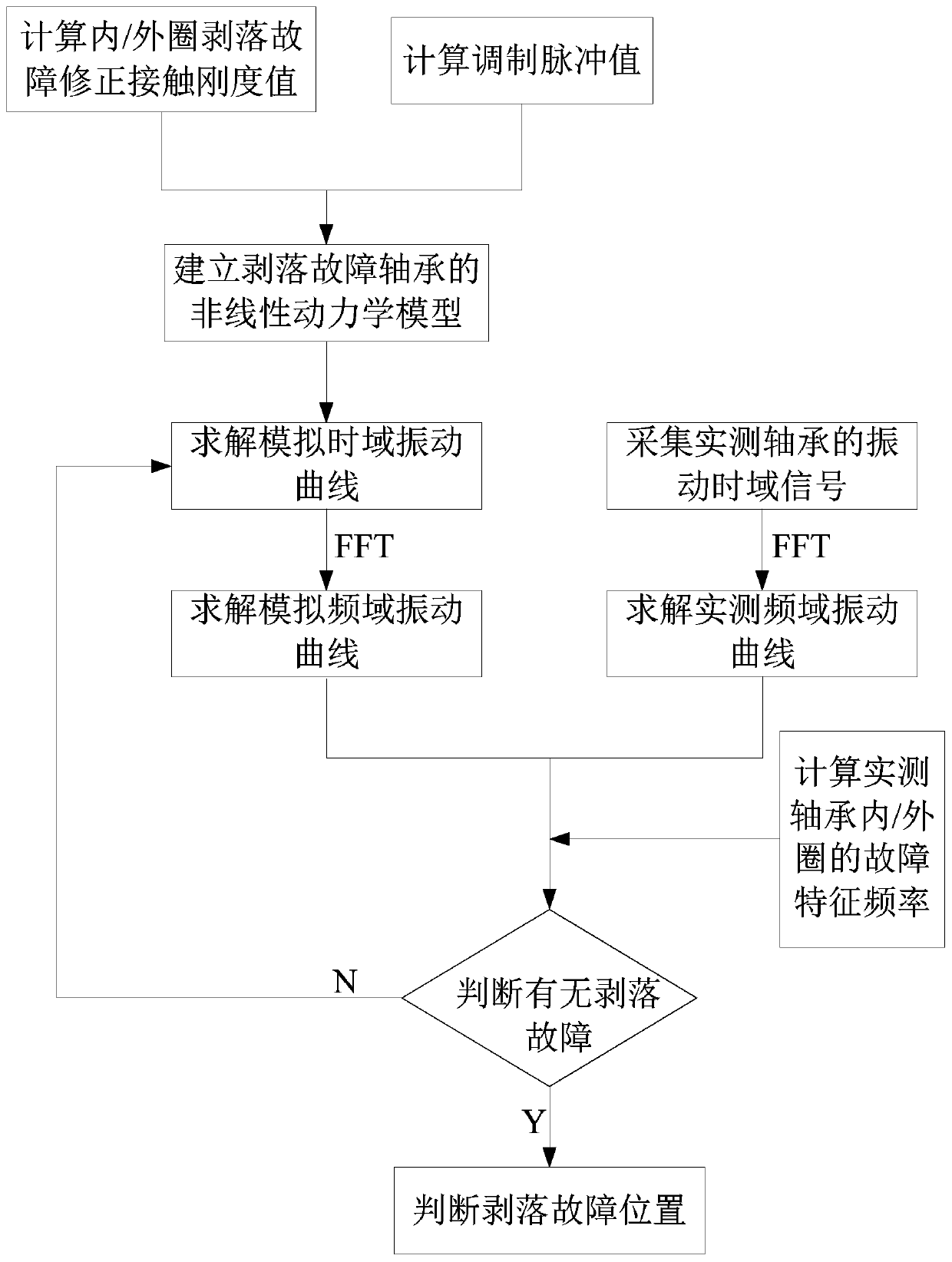

[0051] like figure 1 As shown, a method for judging the spalling position of a rolling bearing includes the following steps:

[0052] Step 1: Establish a nonlinear dynamic model of the spalling fault bearing, and obtain the simulated frequency domain vibration curve of the spalling fault bearing, including the following steps:

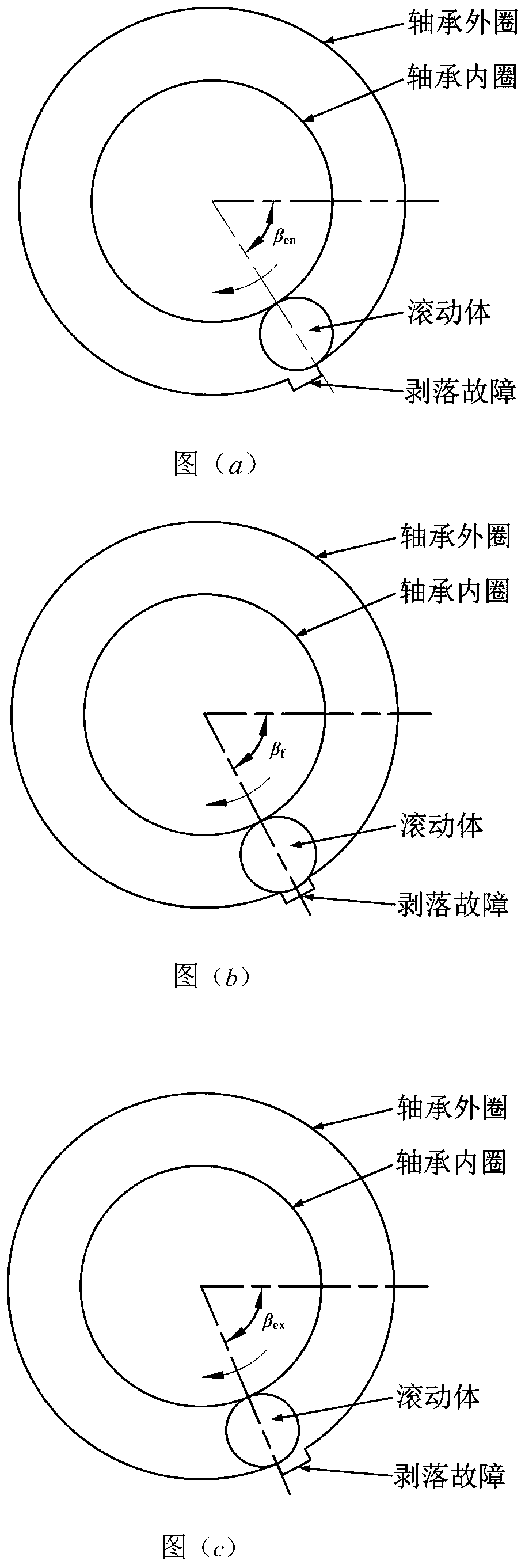

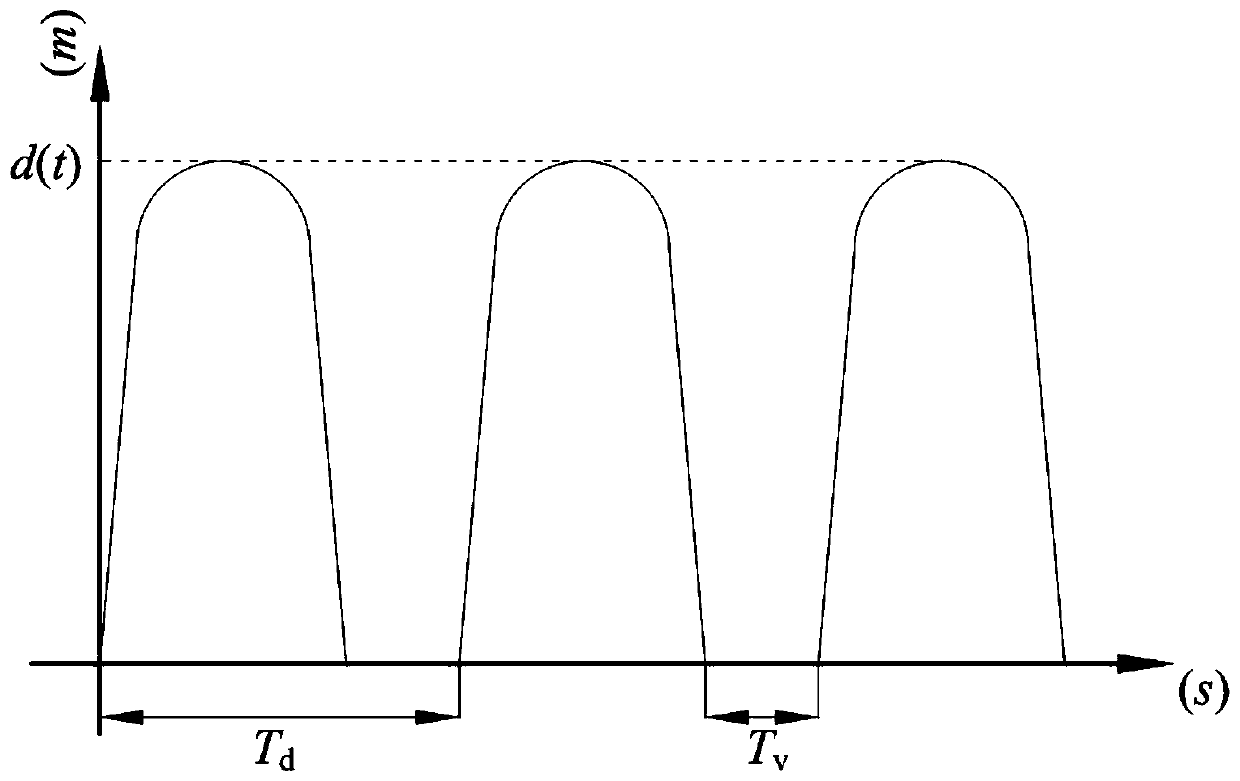

[0053] Step 1.1: First, the lumped parameter model is used to simulate the operating state of the spalling fault bearing, figure 2 It is a schematic diagram of the process of the rolling body when there is a spalling fault in the inner and outer rings of the bearing, and then according to the spalling fault position of the bearing rolling body and the bearing inner / outer ring, the change process of the contact stiffness between the bearing rolling body and the bearing inner / outer ring is obtained, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com