Suspended self-locking type prestress tensioning platform and prestress tensioning and later-period mud jacking operation method thereof

A prestressed, self-locking technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of cumbersome construction procedures, many safety hazards, slow construction progress, etc., to achieve the safety and reliability of the structure itself, and the simple and convenient installation and dismantling. , The effect of convenient operation in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

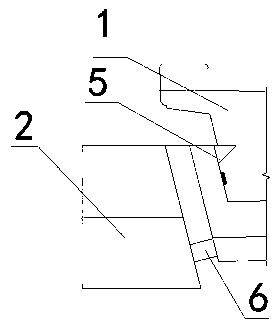

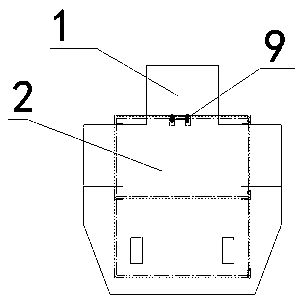

[0023] Such as Figure 1 to Figure 4 As shown, a suspended self-locking prestressed tensioning platform is applied to the prestressed tensioning of the cover beam, including a trapezoidal body frame 2 and a platform panel 3 at the bottom of the frame 2, and the front of the frame 2 is provided with a balanced support top 6, The back of the frame 2 is provided with a safety protection plate 7, the two sides of the frame 2 are provided with safety guardrails 4, and the lower part of the frame 2 facing the side of the ear wall 1 is provided with a balanced support top block 6, and the top of the side facing the ear wall 1 goes outward. A section is extended and a self-locking hook 5 for hooking on the block Y of the ear wall 1 is provided at the end of the extension section. A guide rail 9 is also provided on the top of the frame 2, and the guide rail 9 includes longitudinal guide rails 9-1 and 9 -2 and a transverse guide rail, a chain hoist 11 for hanging the jack 10 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com