Frame-type turnover frame for assisting in welding

A flip-stand, frame-type technology, applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of large use limitations, oil drum welding, and inability to adjust the size of oil drums, and achieve small limitations. , good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

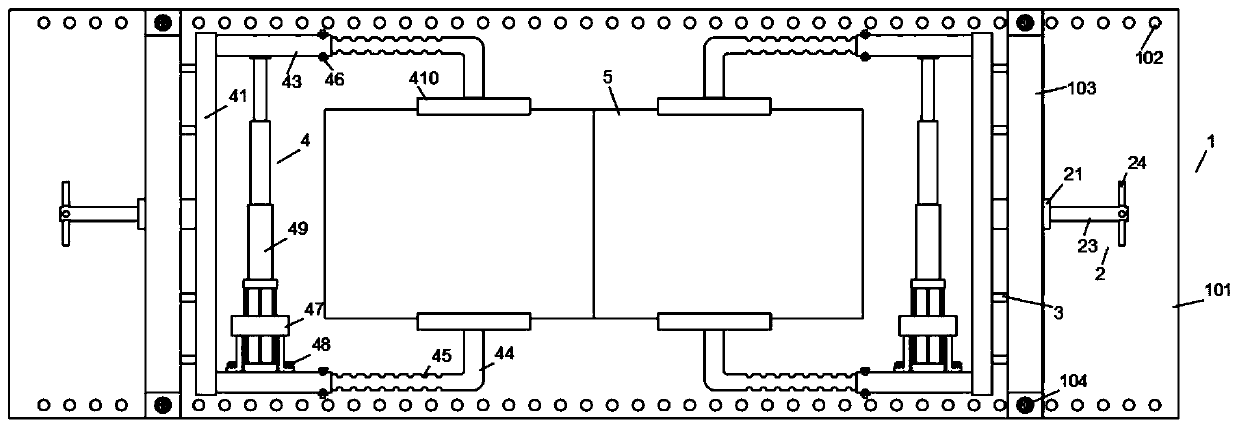

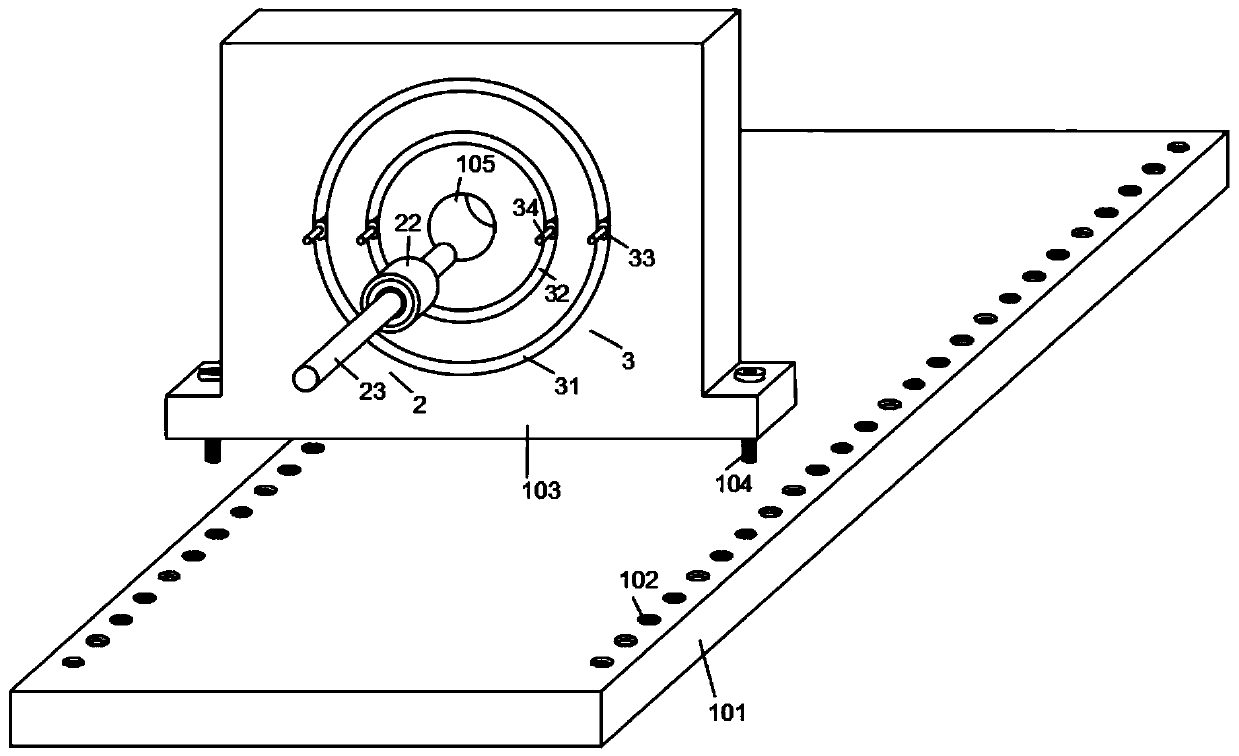

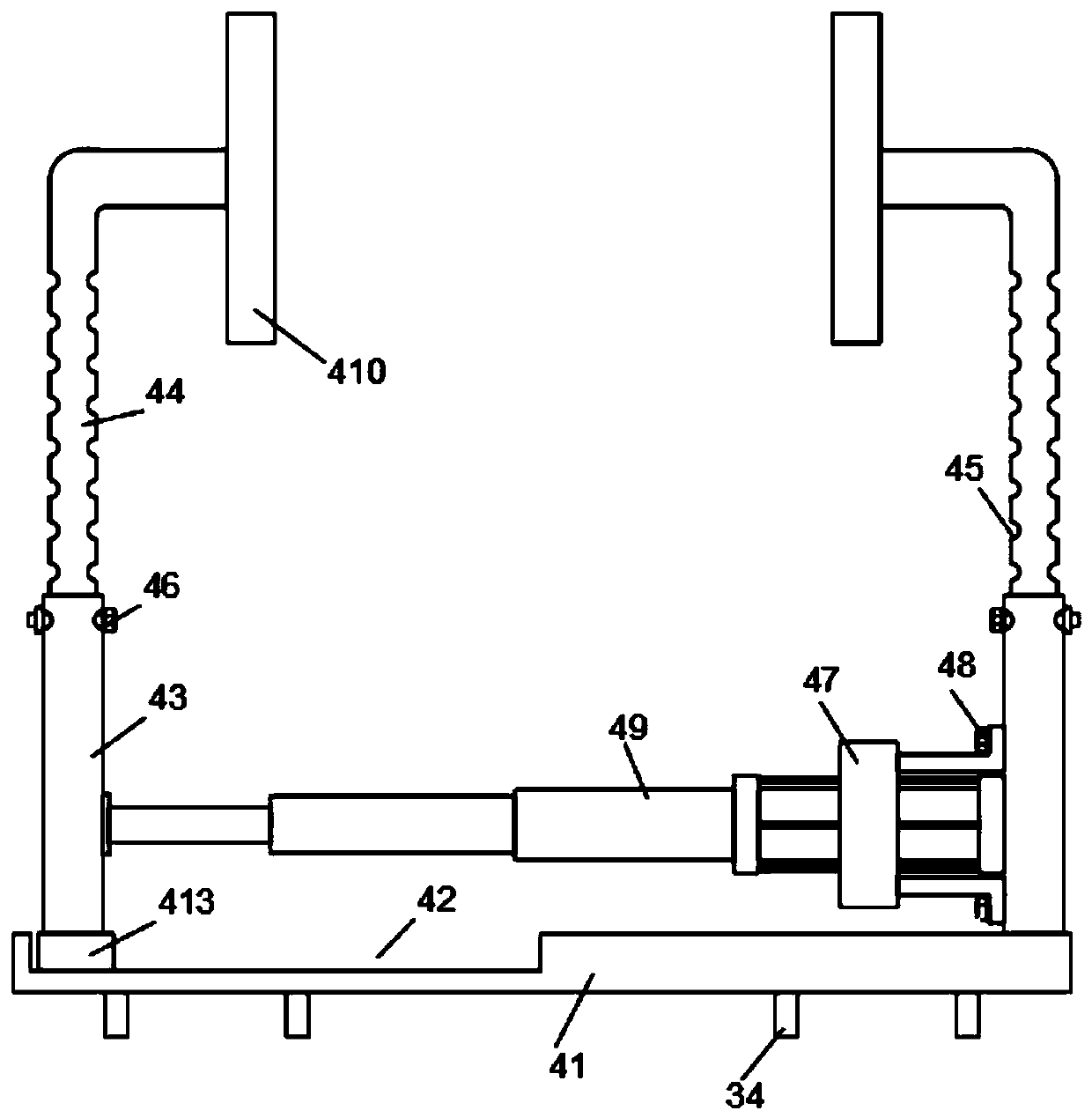

[0025] Embodiment 1: as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a frame-type welding auxiliary turning frame, including a fixing mechanism 1, and the fixing mechanism 1 includes a base 101, a screw groove 102, a T-shaped support seat 103, a limit screw 104 and a connecting groove 105, a number of screw grooves 102 are dug at the front and rear ends of the top of the base 101, T-shaped support seats 103 are arranged on both sides above the base 101, and limit screw rods 104 are inserted at the front and rear ends of the two T-shaped support seats 103, The tops of the side walls of the two T-shaped support bases 103 are drilled with connection grooves 105, and the two T-shaped support bases 103 are respectively connected with the rotating mechanism 2 through the connection grooves 105, and the two T-shaped support bases 103 are respectively located in the connection grooves. The outside of 105 is connected with auxiliary mechanism...

Embodiment 2

[0035] Embodiment 2: When the device is welded, if the side walls of the two oil barrels 5 are welded to each other and away from each other, the entire clamping mechanism 4 on both sides of the device can be removed, and only the two sides are kept. Support plate 41, fixed frame 47, No. 2 bolt 48 and electric telescopic rod 49, two fixed frames 47 are threadedly connected with support plate 41 by No. The side walls of the oil barrels 5 away from each other can clamp and limit the two oil barrels 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com