High-simulation maxillary edentulous jaw soft and hard tissue in-vitro model and preparation method thereof

A hard tissue and edentulous technology, applied in the field of medical models, can solve the problems of being unable to directly simulate the structural state of maxillary tissues, unable to simulate soft tissues, and unable to effectively reflect the hardness of various tissues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

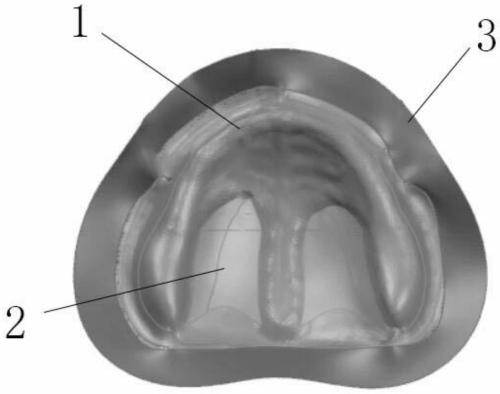

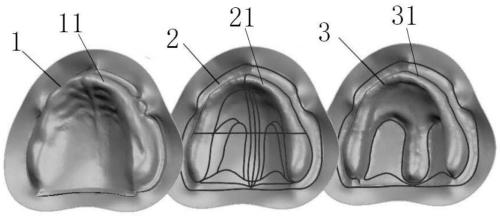

[0032] This embodiment discloses a highly simulated maxillary edentulous maxillary soft and hard tissue in vitro model, including a masticatory mucosa simulation layer 1 consistent with the shape of the masticatory mucosa, a palatal gland simulation layer 2 consistent with the shape of the palatine gland, and a shape consistent with the maxillary hard tissue Maxillary hard tissue simulation layer 3. The masticatory mucosa simulation layer 1, the palatal gland simulation layer 2 and the maxillary hard tissue simulation layer 3 are respectively provided with U-shaped protrusions that are the same as the physiological shape, including: the chewing mucosa simulation layer protrusion 11, the palatal gland simulation layer protrusions Part 21 and the protruding part 31 of the maxillary hard tissue simulation layer.

[0033] The protruding part 31 of the masticatory mucosa simulation layer, the protruding part 21 of the palatine gland simulation layer and the protruding part 31 of th...

Embodiment 2

[0037] This embodiment discloses a method for making the above-mentioned highly simulated maxillary edentulous maxillary soft and hard tissue in vitro model, including the following steps:

[0038] S1. Extract maxillary CBCT data of occlusal separation.

[0039] S2. Obtain the morphological data of maxillary hard tissue, palatine soft tissue and masticatory mucosa by threshold segmentation method; the soft tissue threshold is -156~+10000HU; the hard tissue threshold is +333~+10000HU.

[0040] S3. Correct and reconstruct maxillary hard tissue morphology based on the morphological data of palatal gland soft tissue and masticatory mucosa.

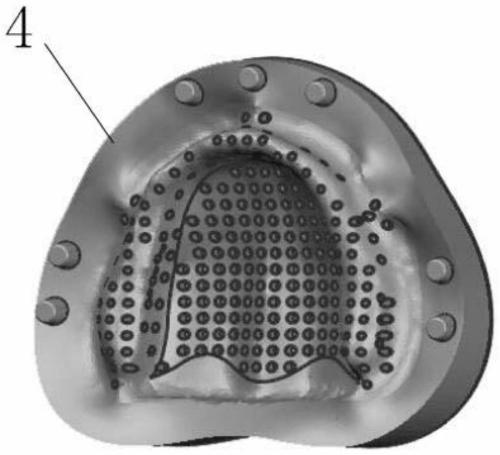

[0041] S4. Carry out digital modeling to maxillary hard tissue, and design the filling mold of palatine gland soft tissue simulation layer 2, chewing mucosa simulation layer 1; Figure 3-5 As shown, the filling mold of palatal gland soft tissue simulation layer 2 and chewing mucosa simulation layer 1 includes chewing mucosa simulation layer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com