car shock absorber

A technology of automobile shock absorbers and outer cylinders, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of poor adaptability of shock absorbers and poor shock absorption effects, and achieve improved shock absorption Shock effect, preventing the piston assembly from bottoming out, and improving the controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

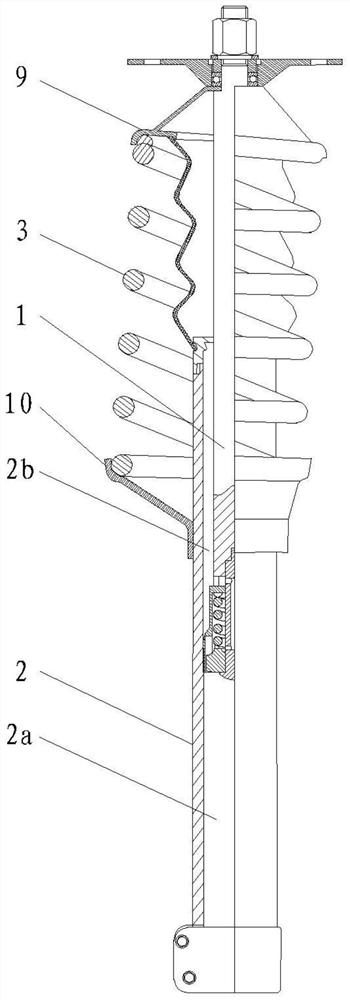

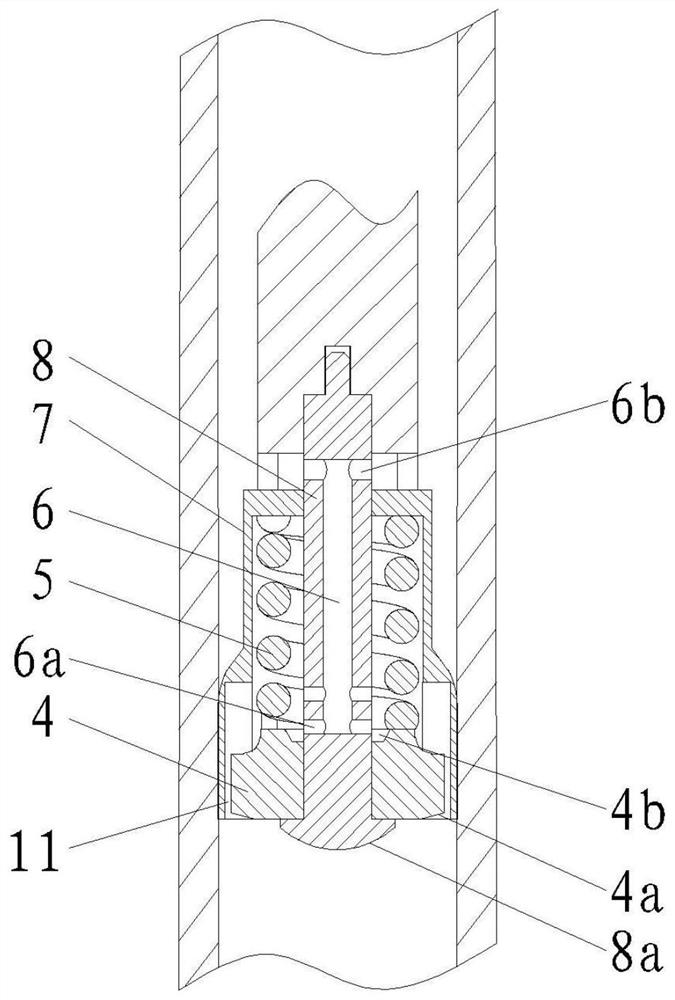

[0020] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the local structure of the present invention;

[0021] As shown in the figure: this embodiment provides an automobile shock absorber, which includes a spool 1, an outer cylinder 2, a piston assembly and a shock absorbing main spring 3. The main spring 3 is placed on the column and is axially sliding and sealingly matched with the inner circle of the outer cylinder. The shock-absorbing main spring 3 is sleeved on the sliding column and the outer cylinder at the same time to provide elastic buffer force for the sliding column. The piston assembly includes a piston body, a sliding sleeve 4 and an elastic 5, the piston body is connected to the sliding column, the piston body has a damping channel 6 connected to the upper and lower chambers of the outer cylinder, and the bottom of the damping channel has several sets of lower passages arranged in the axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com