Hard rock non-explosive tunneling, drilling and splitting integrated trolley

A non-explosive, integrated technology, applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of inaccurate drilling of splitting rods, low construction efficiency, etc., achieve multi-functional operations, improve work efficiency, increase The effect of the drill-through function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

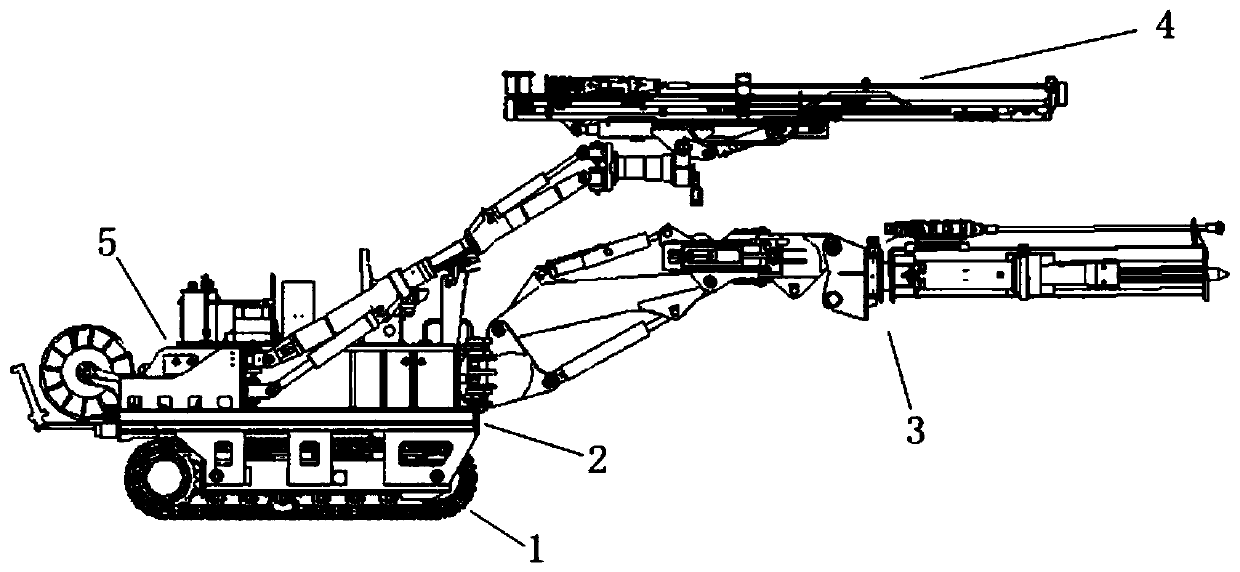

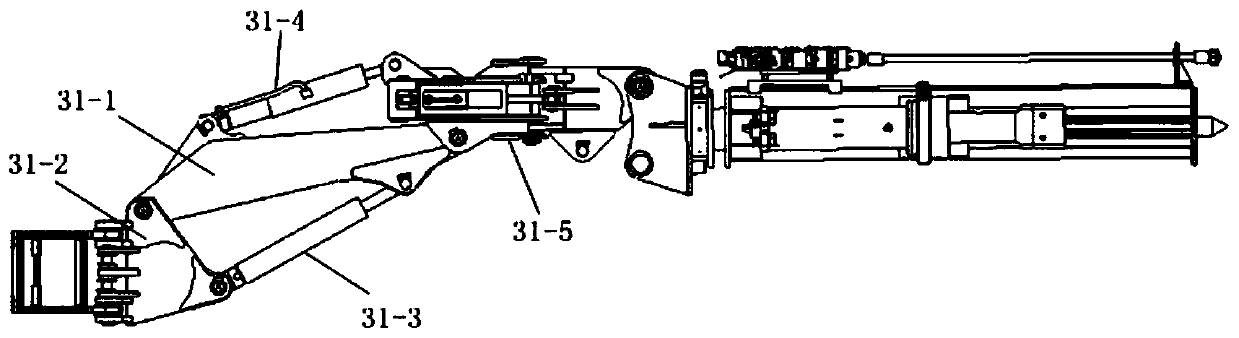

[0027] Such as Figure 1-8 and Figure 10 As shown, a hard rock non-explosive excavation drilling and splitting integrated trolley includes a traveling mechanism 1, a vehicle frame 2 and a drilling and splitting integrated machine 3. The vehicle frame 2 is fixed on the traveling mechanism 1, and the drilling and splitting integrated machine 3 is fixed on the on frame 2. The drilling and splitting machine 3 includes a first drilling arm 31 , a first drilling device 32 , a splitting device 33 , a positioning device 34 , a slewing support 35 and a support 36 . Wherein, the positioning device 34 includes a positioning shaft 34-1 and a positioning apex 34-2, one end of the positioning shaft 34-1 is fixedly connected with the support 36 through the slewing support 35, and the other end is fixedly connected with the positioning apex 34-2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com