Motor rotor press-fitting tool and corresponding mounting method

A technology for motor rotors and press-fitting tooling, which is used in the manufacture of stator/rotor bodies, etc., can solve the problems of multiple alignment, low assembly efficiency, and large footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

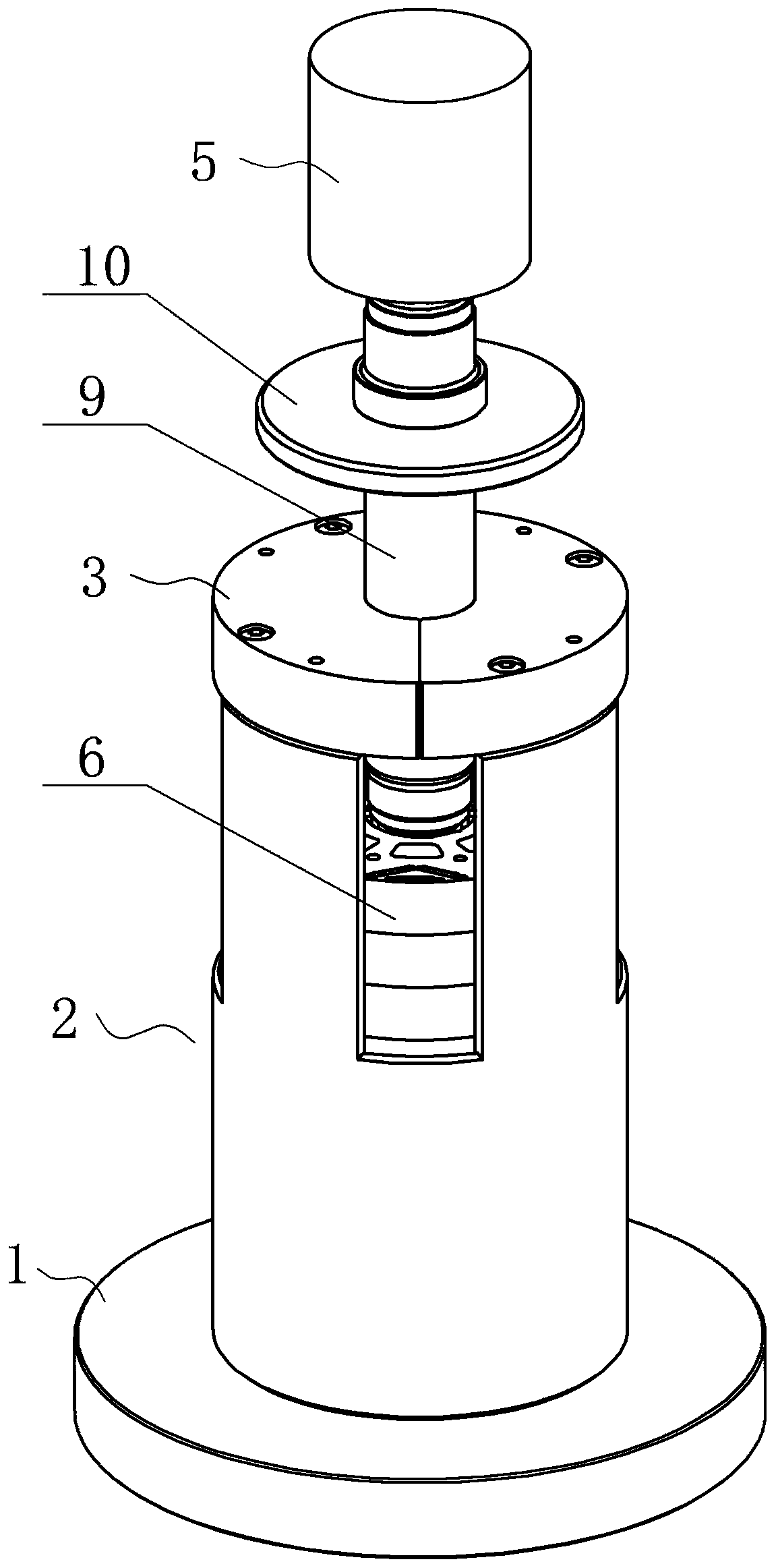

[0024] A motor rotor pressing tooling, see Figure 1-Figure 8 : It includes a base 1, a positioning support 2, a guide block 3, a guide thimble assembly 4, and a pressure head 5. The center of the base 1 is provided with an upwardly convex positioning ring sleeve 11, and the upper end surface of the positioning ring sleeve 11 is surrounded by several concaves. Dodging groove 12, the center of avoiding groove 12 is provided with positioning threaded hole 13, and positioning support 2 comprises lower guide sleeve 21, upper positioning sleeve 22, and the inner ring cavity diameter of lower guiding sleeve 21 is smaller than that of upper positioning sleeve 22. The diameter of the guide cavity, the inner ring part of the upper end surface of the lower guide sleeve 21 is provided with a concave positioning pin hole 211 corresponding to the position of the rivet hole of the rotor core 6, which also includes a matching positioning pin 7, and the positioning pin 7 is inserted. Installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com