Coal-fired boiler staged combustion air depth air staged combustion low NOx control method

An air grading, coal-fired boiler technology, applied in the field of boiler combustion, can solve the problems of NOx emission concentration and fly ash carbon content reduction, lift and other problems, to achieve reduction of NOx regeneration amount, NOx emission concentration reduction, avoid slagging and other problems. The effect of high temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

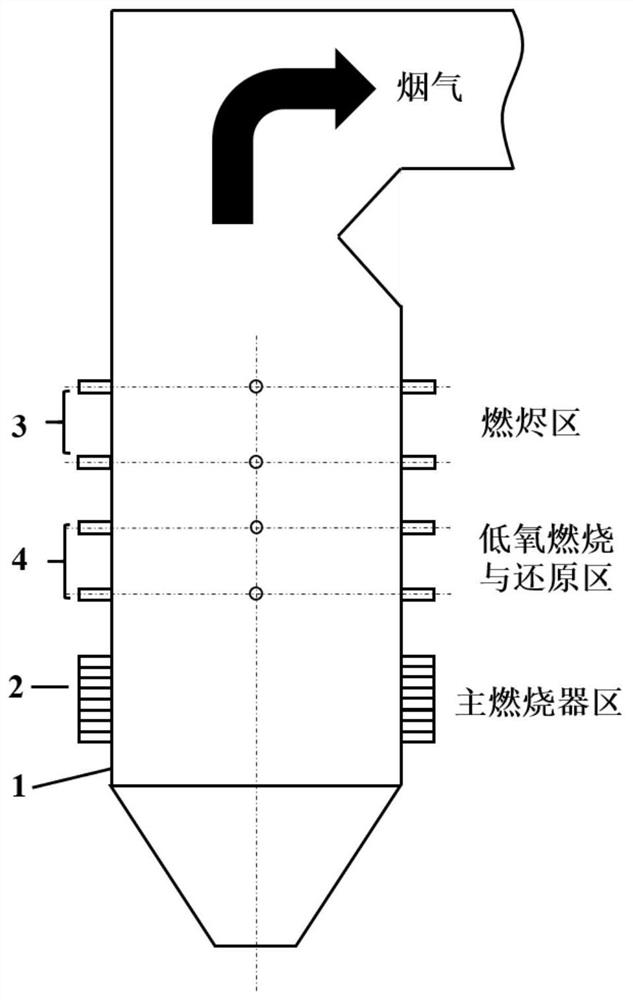

[0028] Such as figure 1 Shown is the application environment of this embodiment, which includes: boiler furnace 1, main burner nozzle 2, main combustion air nozzle 3 and auxiliary combustion air nozzle 4.

[0029] In this embodiment, through the optimal control of the air volume distribution and excess air coefficient of each combustion reaction area in the furnace height direction of the pulverized coal boiler, according to the combustion of the pulverized coal airflow in the furnace and the NOx generation and reduction characteristics, the boiler furnace is arranged along the flue gas flow direction of the furnace height. It is divided into three areas: the main burner area in the lower part of the furnace, the low-oxygen combustion and reduction area in the middle of the furnace, and the embers area in the upper part of the furnace.

[0030] The main burner area at the lower part of the furnace adopts different pulverized coal burners for different combustion modes, adopts ...

Embodiment 2

[0042] Such as image 3 As shown, it is a schematic diagram of the arrangement of auxiliary embering air nozzles in this embodiment. In this embodiment, two auxiliary embering air nozzles 4 are respectively arranged on the front and rear walls 5 and 6 of the boiler furnace and on the left and right side walls 7 and 8, and the auxiliary embering air nozzles 4 are perpendicular to the boiler furnace wall or form a jet flow not exceeding 10° Angle, each auxiliary embers air jet interacts and mixes strongly and evenly with the rising flue gas flow in the furnace, making the oxygen concentration distribution in the furnace cross-section more uniform.

[0043] The auxiliary embering air nozzle includes: a straight jet nozzle located in the center and a swirling secondary air nozzle and / or tertiary air nozzle located around the straight jet nozzle, wherein: the central straight jet assists the embering wind to facilitate reaching In the central area of the furnace, the swirling se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com