Mortar spraying integrated machine

An all-in-one machine and mortar technology, which is applied in construction, building structure, and building material processing, etc., can solve the problems of insufficient mortar density, short horizontal distance, and easy hollowing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] The invention provides a mortar spraying integrated machine, the working principle of which is to feed the mortar through a hydraulic cylinder with a hopper, and spray it through a discharge pipe, so as to improve the head and horizontal distance, ensure the quality of the mortar and reduce the cost input. .

[0024] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

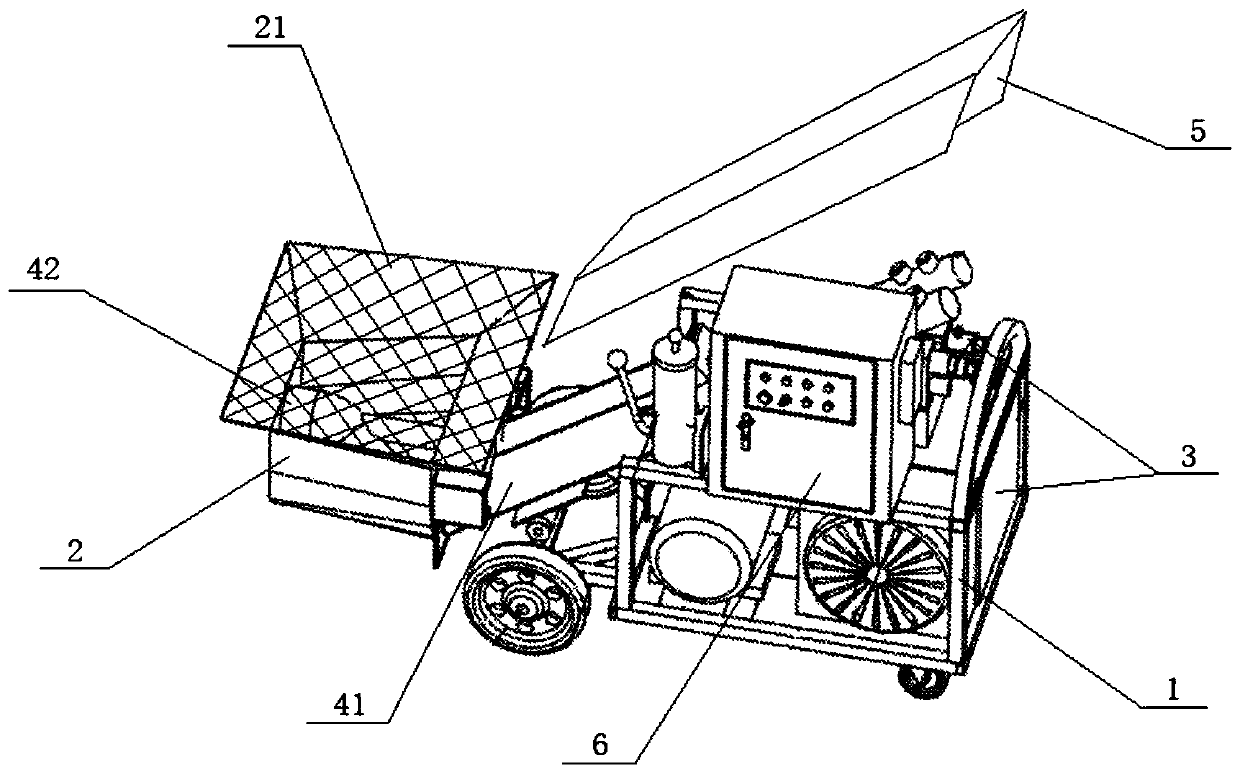

[0025] Such as figure 1 As shown, a mortar spraying all-in-one machine includes an organic body 1, and the body is equipped with production components, hydraulic components, conveying components and protection components;

[0026] The production assembly includes a hopper 2, and a screen 21 is also provided on the hopper;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com