Hoisting machine with pipe cavity frame arc opening rubber supporting pad closing for pipeline construction

A technology for pipeline construction and hoisting machinery, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of small safety factor, affecting the construction process, low stability of composite single-strand steel cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

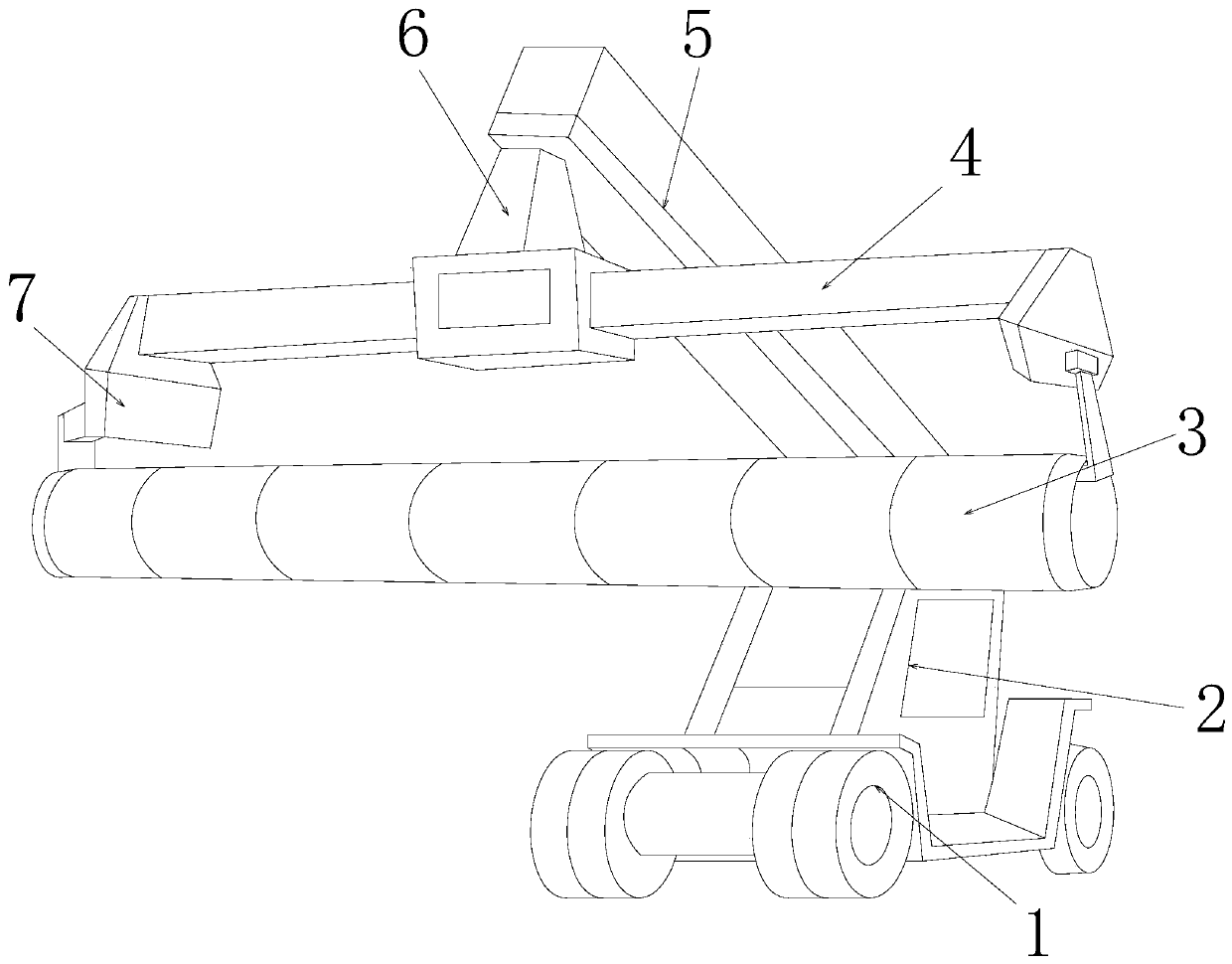

[0033] see Figure 1-Figure 6, the present invention provides a kind of hoisting machine with closed pipe lumen frame and arc opening rubber pad for pipeline construction, its structure includes: hub car chassis 1, driver's cab 2, transverse pipeline 3, hoisting cross bar 4, boom frame 5 , sliding buckle seat 6, rubber bracket pad hanging board frame 7, and described rubber bracket pad hanging board bracket 7 is provided with two and is respectively nested in the left and right sides of hoisting cross bar 4, and described boom bracket 5 is embedded in On the top of the cab 2, the hub car chassis 1 is mechanically connected to the cab 2, the sliding buckle seat 6 is buckled together with the hoisting cross bar 4 and is on the same level, and the crossing pipe 3 is installed on the hoisting cross bar 4. The bottom of the rod 4 is below and parallel to each other, the cross-pipe 3 is fastened together with the rubber bracket pad hanger frame 7, the slide button seat 6 is installe...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a kind of hoisting machine that the pipe lumen frame arc mouth rubber support pad closure is used for pipeline construction, other respects are the same as embodiment 1, the difference is:

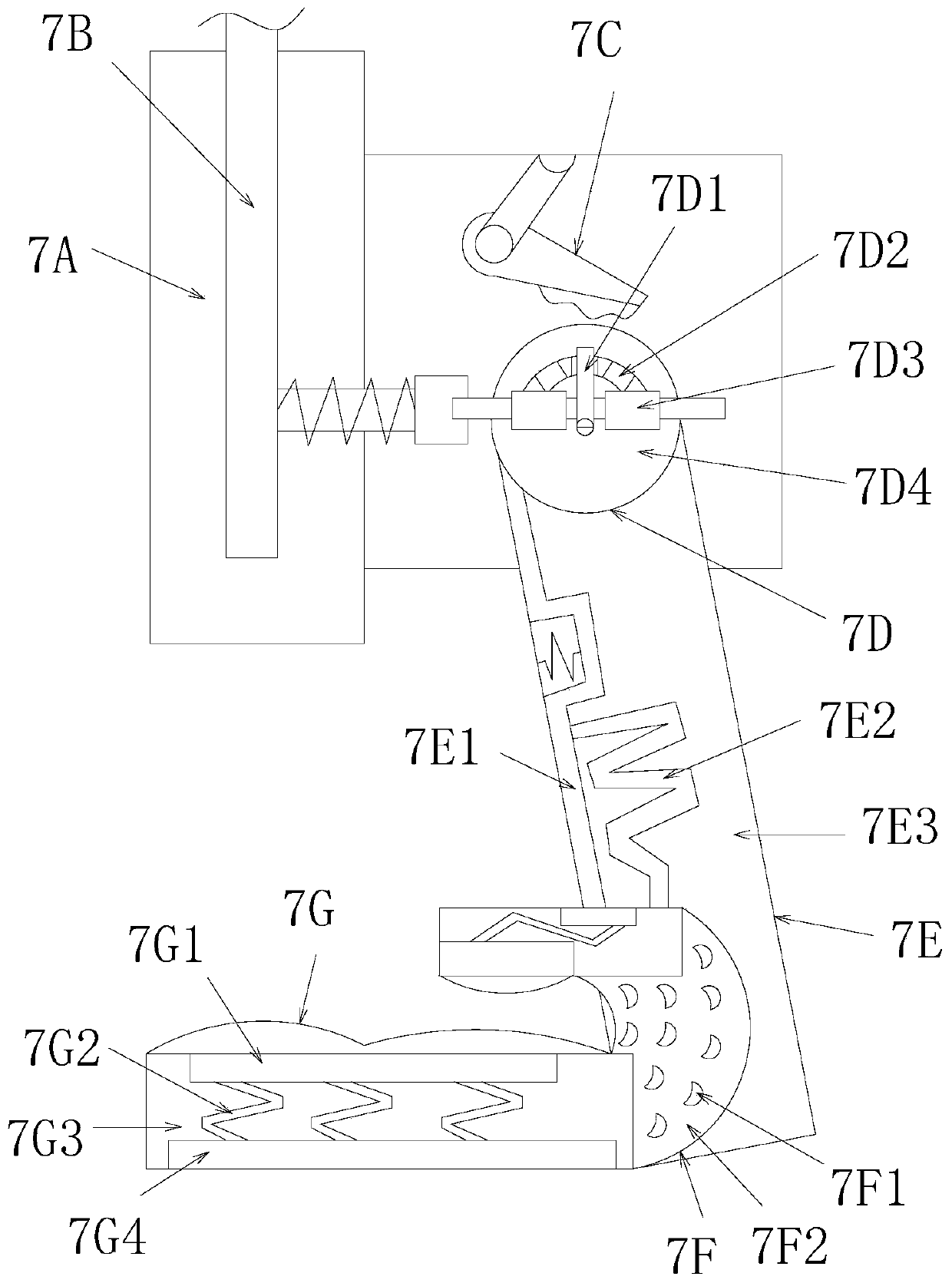

[0041] see figure 2 The rib riser 7E is composed of a side steel rod 7E1, a rib frame 7E2, and a thin vertical plate groove 7E3, and the side steel rod 7E1 and the rib frame 7E2 are inserted into the thin vertical plate groove 7E3 and are in the On the same vertical plane, through the side steel rod 7E1 and the rib frame 7E2 superimposed load-bearing swing, the angular speed of the rod member rotation is consistent, and the working efficiency of the synchronous limit is improved.

[0042] see Figure 4 , the rib frame 7E2 is composed of a knuckle bar 7E21, a short slot frame 7E22, and a column end block 7E23. Inserted under the bottom of the short groove frame 7E22, the knuckle rod 7E21 is a stiffener rod structure with fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com