Double-condenser air conditioning device

An air-conditioning, double-condenser technology, applied in air handling equipment, transportation and packaging, heating/cooling equipment, etc., can solve the mismatch of evaporation effect, condensation and heat dissipation effect, compressor protection can not be normally cooled, and the refrigeration system is not working properly and other issues, to achieve low cost, simple structure, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

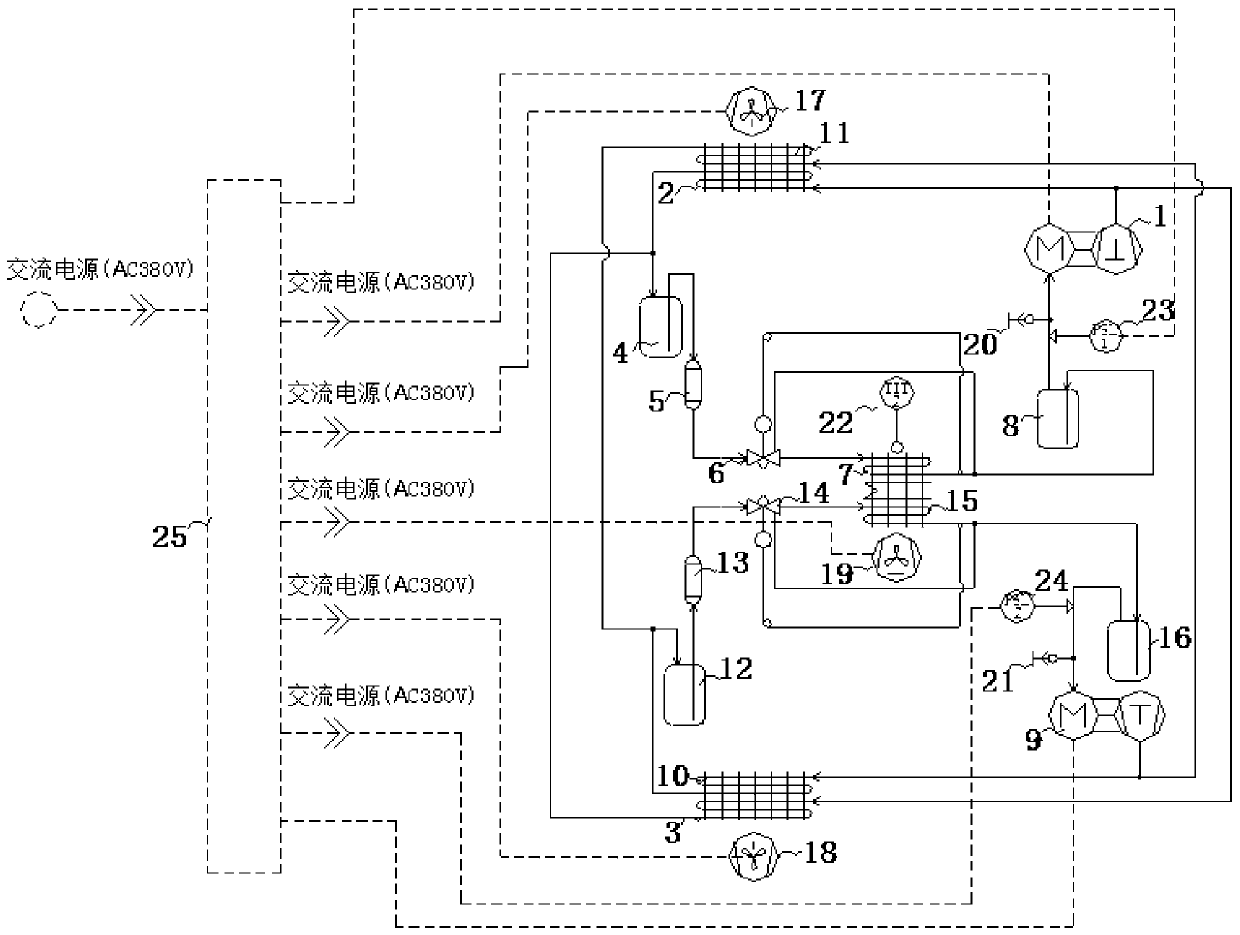

[0028] Such as figure 1 As shown, the double condenser air-conditioning device includes refrigeration system A, refrigeration system B, ventilation system, and electric control system, of which:

[0029] Refrigeration system A includes compressor A1, condenser AI2, condenser AII3, liquid receiver A4, filter A5, thermal expansion valve A6, evaporator A7, and gas-liquid separator A8;

[0030] Refrigeration system B includes compressor B9, condenser BI10, condenser BII11, liquid receiver 12, filter B13, thermal expansion valve B14, evaporator B15, and gas-liquid separator B16;

[0031] In refrigeration system A, compressor A1, condenser AI2, condenser AII3, liquid receiver A4, filter A5, thermal expansion valve A6, evaporator A7, and gas-liquid separator A8 form a refrigeration cycle loop. In refrigeration system B, the compressor B9, condenser BI10, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com